Are you gearing up for an interview for a Hardboard Grinder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hardboard Grinder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

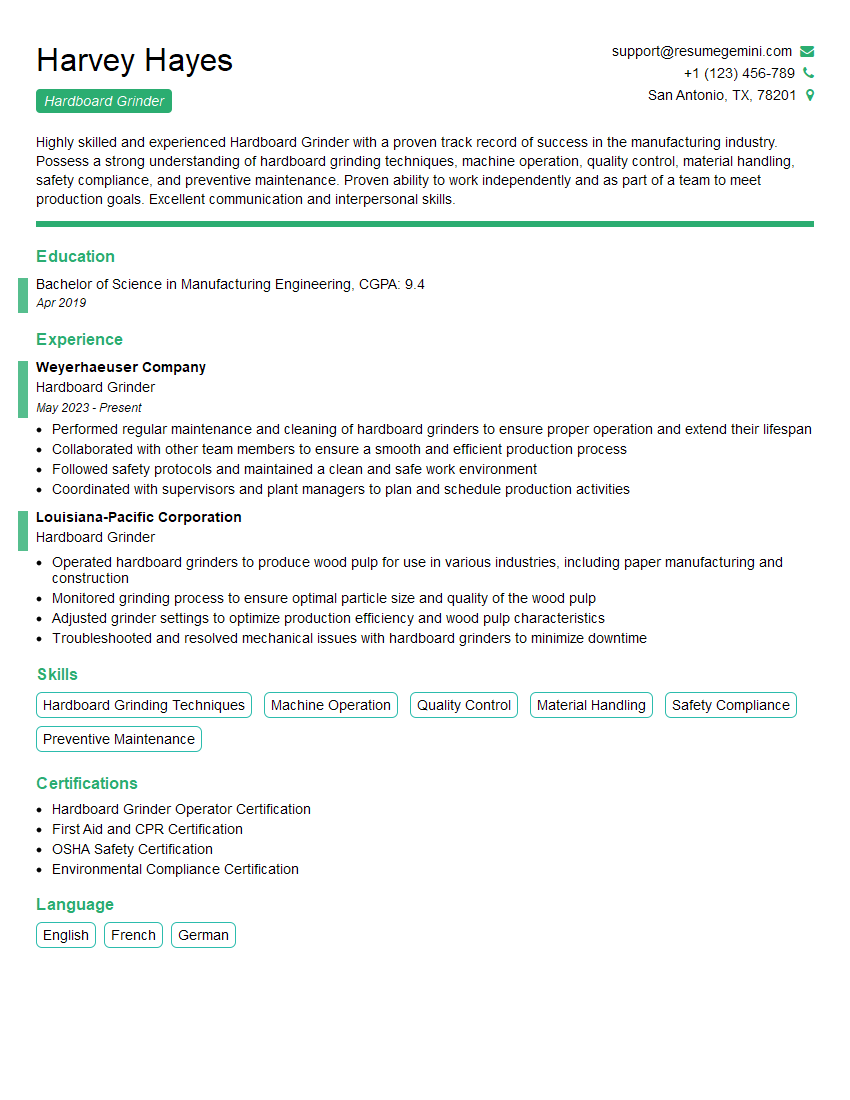

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hardboard Grinder

1. Describe the process of grinding hardboard?

The process of grinding hardboard involves several steps to transform raw wood fibers into smooth, flat panels.

- Fiber Preparation: Wood fibers are obtained from logs or wood chips, which are then mechanically or chemically pulped to separate the cellulose fibers.

- Mat Formation: The separated fibers are mixed with water and formed into a mat on a wire screen. The mat is pressed to remove excess water and create a dense sheet.

- Hardening: The mat enters a hot press where heat and pressure are applied, causing the fibers to bond together and form a hard, durable board.

- Grinding: The hardened board is ground using abrasive belts or stones to create a smooth and flat surface, removing imperfections and ensuring uniform thickness.

- Finishing: After grinding, the hardboard may undergo further processing such as sealing, sanding, or printing to enhance its appearance and properties.

2. What are the different types of hardboard and their applications?

Standard Hardboard

- General-purpose hardboard used in furniture, wall panels, and door cores.

- Available in various grades depending on density and smoothness.

Tempered Hardboard

- Treated with heat and oil to increase strength and water resistance.

- Suitable for exterior applications such as siding, fencing, and outdoor furniture.

Perforated Hardboard

- Contains small holes or perforations for sound absorption or ventilation.

- Used in architectural acoustics, speaker grilles, and perforated ceilings.

High-Density Hardboard

- Extremely dense and durable, making it ideal for heavy-duty applications.

- Used in countertops, flooring, and industrial components.

3. What are the key factors that affect the quality of hardboard grinding?

- Abrasive Belt Quality: The sharpness and grit of the abrasive belts used in grinding significantly impact the smoothness and precision of the finished surface.

- Machine Calibration: The accuracy of the grinding machine, including proper alignment and calibration, ensures consistent thickness and flatness.

- Feed Rate: The speed at which the hardboard is fed through the grinding machine determines the amount of material removed and the surface finish.

- Grain Direction: Grinding with the grain helps minimize tearing and ensures a cleaner cut.

- Dust Control: Effective dust extraction systems prevent excessive buildup and ensure a safe and clean work environment.

4. How do you ensure the accuracy and consistency of hardboard grinding?

- Regular Machine Inspection and Calibration: Regularly checking and calibrating the grinding machine ensures optimal performance and accuracy.

- Use of Precision Measurement Tools: Micrometers or calipers are used to measure the thickness and flatness of the hardboard, ensuring it meets specifications.

- Implementation of Quality Control Procedures: Establishing clear quality standards and performing regular inspections helps identify and correct any deviations.

- Training and Supervision of Operators: Providing proper training and ongoing supervision to operators ensures they adhere to correct grinding techniques and maintain high-quality standards.

- Continuous Improvement: Regularly reviewing processes and seeking feedback from operators helps identify areas for improvement and optimize grinding operations.

5. Describe the safety protocols and precautions necessary for hardboard grinding operations.

- Proper Ventilation: Adequate ventilation is essential to remove dust and fumes generated during grinding.

- Personal Protective Equipment: Operators must wear safety glasses, gloves, and respiratory masks to protect against dust and flying debris.

- Machine Guarding: Grinding machines should have proper guards to prevent accidental contact with moving parts.

- Fire Safety: Grinding operations can generate sparks, so fire extinguishers should be readily available and regularly inspected.

- Noise Control: Grinding operations can produce noise, so hearing protection is important for operators and nearby personnel.

6. What types of maintenance are required for hardboard grinding machines?

- Regular Cleaning and Inspection: Daily cleaning and inspection of the machine and its components ensure optimal performance and prevent breakdowns.

- Belt Replacement: Abrasive belts should be replaced regularly to maintain sharpness and prevent uneven grinding.

- Lubrication: Regular lubrication of moving parts reduces wear and tear, extending the machine’s lifespan.

- Calibration and Alignment: Periodic calibration and alignment ensure precision grinding and prevent defects.

- Preventive Maintenance Schedule: Implementing a comprehensive preventive maintenance schedule helps identify potential issues early and prevent costly repairs.

7. How do you troubleshoot common problems encountered during hardboard grinding?

- Uneven Surface: Check belt sharpness, machine alignment, and feed rate to identify and resolve the cause of uneven grinding.

- Excessive Dust: Inspect dust extraction system for blockages or leaks, and consider using higher-quality abrasive belts.

- Burning or Discoloration: Adjust feed rate, reduce pressure, or use a coarser abrasive belt to prevent overheating the hardboard surface.

- Tearing or Splintering: Ensure grinding with the grain, use sharper belts, and adjust the feed rate to minimize material damage.

- Machine Vibration: Check machine alignment, tighten loose bolts or bearings, and inspect belts for damage or imbalances.

8. What techniques or best practices can you share to improve the efficiency of hardboard grinding operations?

- Optimized Feed Rate: Determine the optimal feed rate to maximize output while maintaining quality.

- Sharp Abrasive Belts: Regularly replace dull belts to ensure efficient grinding and prevent surface defects.

- Proper Machine Maintenance: Regular maintenance and calibration minimize downtime and ensure consistent performance.

- Automated Loading and Unloading: Consider automating the loading and unloading process to improve efficiency and reduce labor costs.

- Process Optimization: Regularly review and analyze grinding operations to identify bottlenecks and implement improvements.

9. How do you stay up-to-date on the latest advancements in hardboard grinding technology?

- Industry Trade Shows and Exhibitions: Attend industry events to learn about new technologies and advancements.

- Technical Journals and Publications: Subscribe to relevant publications to stay informed about the latest research and developments.

- Online Resources: Utilize online forums, websites, and social media platforms to connect with industry experts and learn from their experiences.

- Manufacturer Training and Webinars: Participate in training programs and webinars offered by equipment manufacturers to gain in-depth knowledge of new technologies.

- Collaboration with Peers and Experts: Network with other professionals in the field and exchange knowledge and best practices.

10. What are your career goals and aspirations as a Hardboard Grinder?

My career aspirations as a Hardboard Grinder are to become a highly skilled and experienced professional in the field. I am eager to contribute my knowledge and skills to optimize grinding operations, improve productivity, and enhance the quality of hardboard products.

In the long term, I envision myself as a lead operator or supervisor, responsible for training and mentoring new team members, implementing innovative techniques, and ensuring the smooth running of the grinding department. I am confident that my dedication, hard work, and continuous learning will enable me to excel in this role and contribute to the success of the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hardboard Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hardboard Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hardboard Grinder is a skilled professional responsible for operating and maintaining equipment used in the production of hardboard sheets. These individuals play a crucial role in ensuring the quality and efficiency of the production process.

1. Material Handling

Hardboard Grinders are responsible for managing incoming wood chips and other materials required for hardboard production. They ensure that the materials meet the necessary specifications and are properly loaded into the grinding equipment.

- Inspecting incoming materials (wood chips, sawdust, etc.) for consistency, size, and quality

- Feeding materials into grinding machines and monitoring the grinding process

2. Machine Operation

Hardboard Grinders operate complex grinding machines that transform wood chips into wood pulp. They adjust the machines’ settings to achieve the desired pulp consistency and texture.

- Operating and monitoring grinding machines to produce wood pulp

- Adjusting machine settings to optimize grinding efficiency and pulp quality

- Troubleshooting and resolving any issues with grinding machines

3. Quality Control

Hardboard Grinders perform quality control checks throughout the grinding process to ensure that the pulp meets the specified specifications. They analyze pulp samples and make adjustments to the grinding process as needed.

- Inspecting pulp samples to ensure compliance with quality standards

- Conducting tests on pulp to determine its consistency, moisture content, and other properties

4. Maintenance and Repair

Hardboard Grinders are responsible for basic maintenance and repair of grinding equipment. They perform regular inspections, lubricate moving parts, and replace worn components.

- Performing routine maintenance tasks to ensure equipment longevity

- Troubleshooting and repairing any malfunctions in grinding machines

- Reporting any major issues to supervisors for further maintenance or repairs

5. Safety and Compliance

Hardboard Grinders are responsible for adhering to safety protocols and maintaining a clean and hazard-free work environment. They wear appropriate safety gear and follow established procedures to minimize risks.

- Complying with all safety regulations and guidelines

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work area

6. Communication and Coordination

Hardboard Grinders communicate effectively with supervisors, colleagues, and other departments to ensure smooth production processes. They keep records of grinding operations and report any anomalies or quality issues.

- Communicating with supervisors and colleagues to coordinate production schedules

- Keeping accurate records of grinding operations and pulp quality

- Reporting any production issues or quality concerns to appropriate personnel

Interview Tips

Interview preparation is essential for any job seeker. Here are some tips to help candidates ace their Hardboard Grinder interview:

1. Research the Company and Role

Before the interview, take the time to thoroughly research the company and the specific Hardboard Grinder role you are applying for. This will demonstrate your interest and enthusiasm for the position.

- Visit the company website and read about their history, values, and products/services.

- Review the job description and identify the key responsibilities and qualifications required.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview.

- Tell me about your experience in hardboard production.

- Describe your role in maintaining and troubleshooting grinding equipment.

- How do you ensure that the wood pulp meets the required specifications?

- What are the safety precautions you observe when operating grinding machines?

3. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that are most relevant to the Hardboard Grinder role. Provide specific examples from your previous work history to demonstrate your capabilities.

- Highlight your expertise in operating and maintaining grinding machines.

- Emphasize your understanding of wood pulp characteristics and quality control processes.

- Share your experience in troubleshooting and resolving equipment issues.

4. Ask Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your engagement and interest in the role. Prepare a few questions that show you are curious and have done your research.

- What are the current challenges faced by the hardboard production department?

- What technologies are being used to optimize the grinding process?

- What opportunities are there for career growth within the company?

5. Be Professional and Enthusiastic

Throughout the interview, maintain a professional demeanor and show enthusiasm for the position. Be respectful, make eye contact, and actively listen to the interviewer’s questions.

- Dress appropriately and arrive on time for the interview.

- Be polite and respectful to the interviewer and other staff members.

- Show genuine interest in the role and the company.

6. Follow Up

After the interview, send a thank-you note to the interviewer expressing your appreciation for their time and consideration. This shows your continued interest in the position and leaves a positive impression.

- Send a personalized thank-you note within 24 hours of the interview.

- Reiterate your interest in the role and highlight any key points from the interview.

- Inquire about the next steps in the hiring process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hardboard Grinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hardboard Grinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.