Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hardboard Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

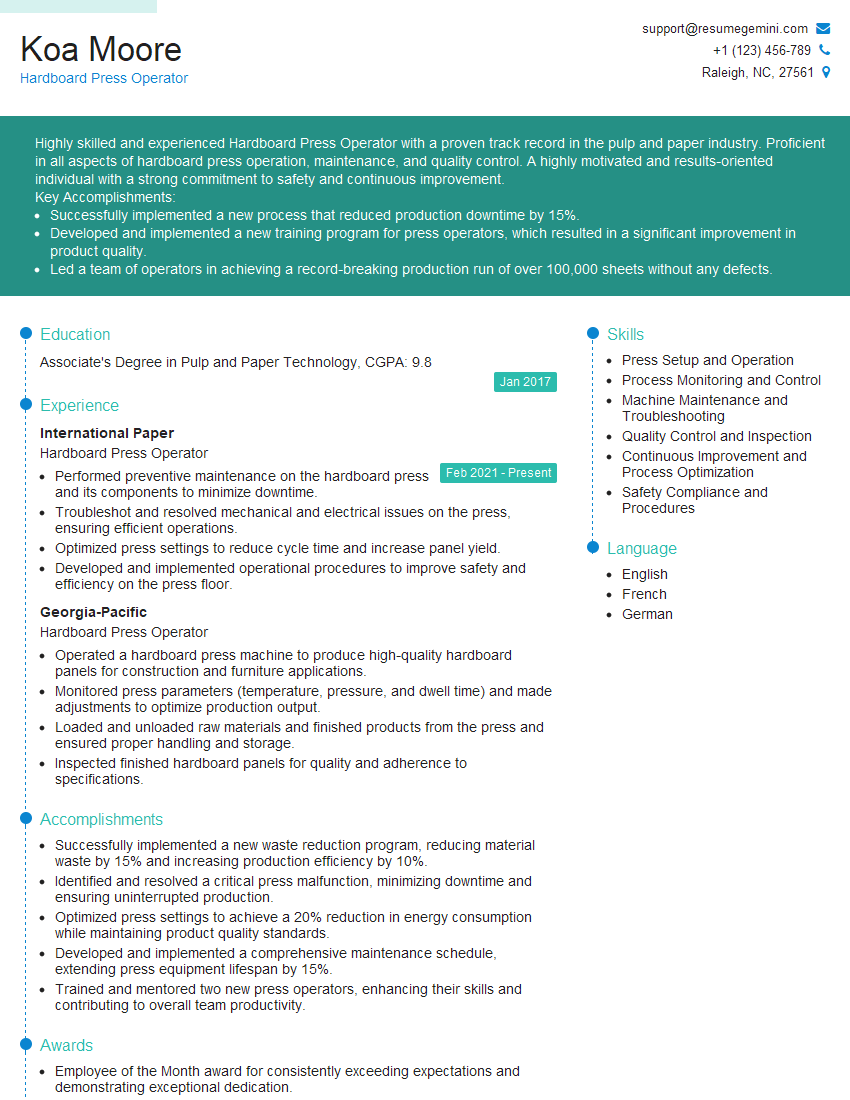

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hardboard Press Operator

1. What are the key responsibilities of a Hardboard Press Operator?

As a Hardboard Press Operator, my primary responsibilities include:

- Operating and monitoring hardboard presses to produce hardboard sheets that meet specifications.

- Setting up and adjusting press settings, including temperature, pressure, and cycle time.

- Loading and unloading raw materials and finished products.

- Conducting quality checks on hardboard sheets to ensure they meet standards.

- Maintaining and cleaning presses and work area to ensure safety and efficiency.

2. How do you ensure the quality of the hardboard sheets produced?

Pre-Production Checks

- Inspecting raw materials for defects and ensuring they meet specifications.

- Verifying press settings and making adjustments as needed.

During Production

- Monitoring press temperatures and pressures to ensure optimal conditions.

- Observing the sheets during pressing to identify any abnormalities or defects.

Post-Production Checks

- Conducting visual inspections for cracks, delamination, or other defects.

- Measuring sheet thickness, density, and other physical properties to ensure compliance.

3. What maintenance tasks are you responsible for as a Hardboard Press Operator?

To ensure smooth operation and optimal performance, I am responsible for the following maintenance tasks:

- Lubricating moving parts, such as bearings and chains.

- Inspecting and replacing worn or damaged components, such as gaskets and seals.

- Cleaning equipment, including presses, conveyors, and work surfaces.

- Performing minor repairs, such as replacing fuses or tightening bolts.

- Reporting any major issues or malfunctions to supervisors for timely resolution.

4. How do you troubleshoot common problems that may arise during hardboard production?

Some common problems and their troubleshooting steps include:

- Sheet delamination: Check press temperature and pressure settings, raw material quality, and pressing time.

- Uneven sheet thickness: Inspect the press bed for flatness, check pressure distribution, and adjust settings accordingly.

- Sheet surface defects: Examine raw materials for impurities or damage, adjust pressing conditions, and clean the press.

- Press malfunctions: Identify the source of the issue (e.g., electrical, mechanical), consult the manufacturer’s manual, and contact maintenance personnel if necessary.

5. How do you handle safety precautions when operating hardboard presses?

Safety is paramount in my role. I adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Following lockout/tagout procedures before performing maintenance or repairs.

- Maintaining a clean and organized work area to prevent accidents.

- Being aware of the location of emergency stops and knowing the evacuation procedures.

- Receiving regular safety training and staying up-to-date on industry best practices.

6. How do you measure the efficiency of your hardboard production process?

To assess efficiency, I track the following metrics:

- Output rate: Number of hardboard sheets produced per hour.

- Sheet quality: Percentage of sheets that meet or exceed quality standards.

- Downtime: Time spent on maintenance, repairs, or other interruptions.

- Material utilization: Percentage of raw materials used to produce finished sheets.

- Energy consumption: Monitoring press settings and energy usage to optimize efficiency.

7. How do you stay up-to-date on the latest advancements in hardboard manufacturing technology?

To maintain my knowledge and skills, I actively engage in the following activities:

- Attending industry conferences and seminars.

- Reading technical journals and industry publications.

- Participate in online forums and discussions related to hardboard production.

- Seeking training from equipment manufacturers or industry experts.

- Collaborating with colleagues and exchanging ideas to identify improvement opportunities.

8. How do you handle situations where there are production targets to meet but unforeseen challenges arise?

When faced with such situations:

- Assess the situation: Identify the cause of the challenge and its potential impact.

- Prioritize tasks: Determine which tasks are most critical to meet the production targets.

- Communicate: Inform supervisors and colleagues about the challenges and seek support where needed.

- Troubleshoot and resolve: Work systematically to resolve the issue, consult with experts if necessary.

- Adjust production schedule: If necessary, adjust the schedule to accommodate the challenges while minimizing impact on targets.

9. What is your approach to working in a team environment as a Hardboard Press Operator?

In a team environment:

- Collaboration: Work closely with colleagues to achieve common goals.

- Communication: Share information, updates, and concerns promptly.

- Support: Assist team members with tasks and provide support when needed.

- Respect: Value and respect the opinions and contributions of others.

- Flexibility: Adapt to changing priorities and support the team as required.

10. How do you prioritize quality control while maintaining production efficiency?

To balance quality control and efficiency:

- Establish clear standards: Define specific quality parameters and tolerances.

- Implement inspection procedures: Regularly inspect raw materials, work-in-progress, and finished products.

- Use quality control tools: Utilize gauges, measuring devices, and other tools to ensure accuracy.

- Train staff: Ensure that all operators are trained on quality control procedures.

- Continuous improvement: Monitor quality metrics and identify areas for improvement to enhance efficiency without compromising quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hardboard Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hardboard Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Hardboard Press Operator plays a pivotal role in the production of hardboard, ensuring the smooth and efficient operation of the pressing machines. The main responsibilities include:

1. Operation of Hardboard Press Machine

Operating and monitoring the hardboard press machine, ensuring optimal performance and product quality.

- Setting up and adjusting the press machine according to production specifications.

- Loading and unloading raw materials into and out of the press machine.

2. Quality Control

Conducting regular quality checks on the finished hardboard products, ensuring they meet the required standards.

- Inspecting the hardboard for defects, such as cracks, tears, or uneven thickness.

- Taking corrective actions to address any quality issues.

3. Production Monitoring

Monitoring the production process and making adjustments as needed to maintain efficiency and output.

- Tracking production rates and identifying areas for improvement.

- Conducting preventative maintenance checks on the press machine to minimize downtime.

4. Safety Compliance

Adhering to all safety protocols and regulations to ensure a safe work environment.

- Wearing appropriate safety gear and following safety procedures.

- Reporting any potential hazards or safety concerns to supervisors.

Interview Tips

To prepare for an interview for the Hardboard Press Operator position, consider these tips:

1. Research the Company and Industry

Learn about the company’s history, culture, and products. Understanding the industry trends and technological advancements will demonstrate your interest and knowledge.

- Read the company website and industry publications.

- Attend industry events or webinars to stay informed.

2. Practice Answering Common Interview Questions

Prepare for questions related to your technical skills, experience, and safety awareness. Consider using the STAR method to structure your answers:

- Situation: Describe the situation or task.

- Task: Explain your role and responsibilities.

- Action: Outline the actions you took.

- Result: Describe the positive outcome or impact.

3. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining hardboard press machines. Mention specific knowledge of controls, hydraulics, and electrical systems.

- Provide examples of troubleshooting and resolving technical issues.

- Discuss any certifications or training you have received.

4. Showcase Your Quality Consciousness

Demonstrate your attention to detail and commitment to producing high-quality hardboard products. Explain how you ensure consistent quality through inspections and corrective actions.

- Share examples of implementing quality control measures.

- Discuss your understanding of industry standards and regulations.

5. Emphasize Safety and Compliance

Stress your commitment to safety and adherence to all relevant protocols. Describe your experiences in maintaining a safe work environment and preventing accidents.

- Provide examples of identifying and mitigating potential hazards.

- Explain your understanding of OSHA regulations and industry best practices.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hardboard Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!