Are you gearing up for an interview for a Hardboard Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hardboard Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

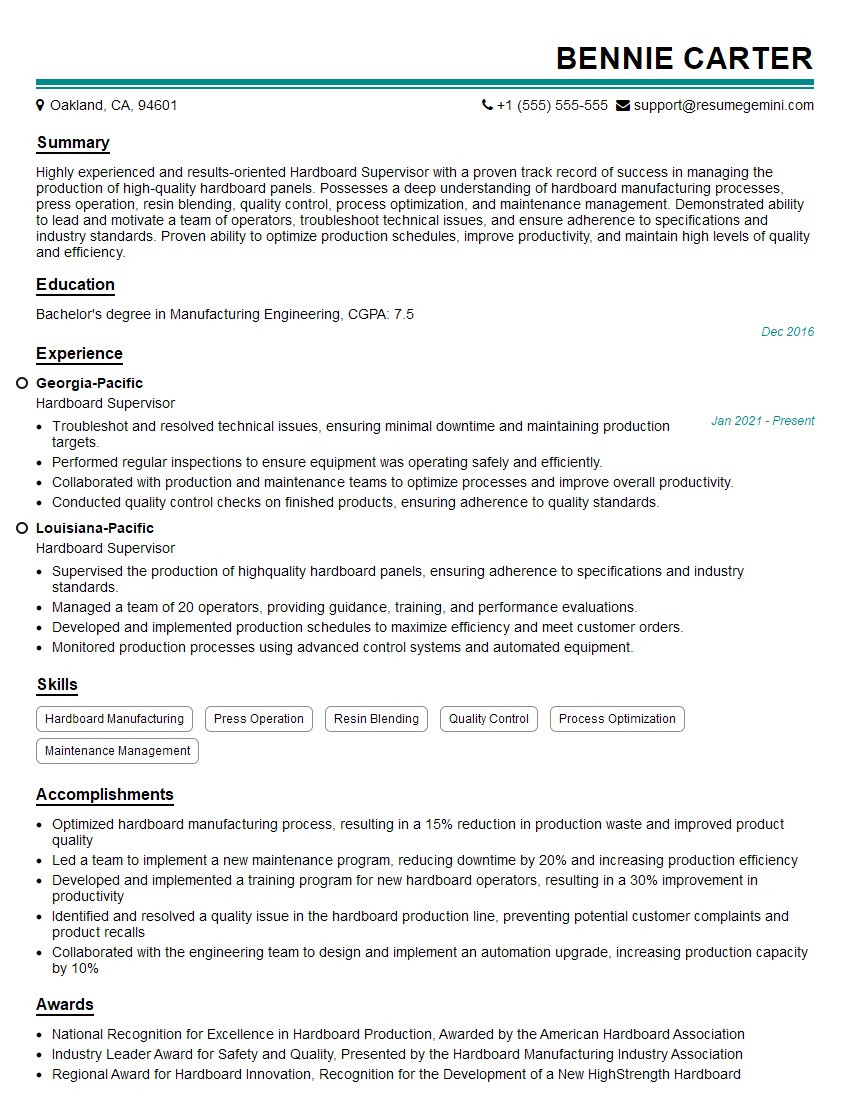

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hardboard Supervisor

1. What are the key responsibilities of a Hardboard Supervisor?

As a Hardboard Supervisor, my responsibilities would include:

- Overseeing the day-to-day operations of the hardboard production process

- Ensuring that all products meet quality standards

- Maintaining a safe and efficient work environment

- Training and supervising staff

- Troubleshooting any problems that arise

2. What are the different types of hardboard?

Types of Hardboard

- Standard hardboard

- Tempered hardboard

- Oil-tempered hardboard

- Perforated hardboard

- Decorative hardboard

Applications of Hardboard

- Furniture

- Cabinetry

- Shelving

- Wall paneling

- Automotive parts

3. What are the key factors that affect the quality of hardboard?

The key factors that affect the quality of hardboard include:

- The quality of the raw materials

- The manufacturing process

- The storage conditions

4. What are the different grades of hardboard?

Hardboard is typically graded according to its thickness, density, and surface finish. The most common grades of hardboard are:

- S1S (one side smooth)

- S2S (two sides smooth)

- T1-11 (textured one side, striated one side)

- U1S (unfinished one side)

5. What are the most common defects in hardboard?

The most common defects in hardboard include:

- Warping

- Blistering

- Cracking

- Delamination

- Surface voids

6. How do you troubleshoot problems with hardboard production?

To troubleshoot problems with hardboard production, I would first try to identify the root cause of the problem. Once I have identified the root cause, I would then develop a plan to correct the problem.

Some of the most common problems with hardboard production include:

- Poor quality raw materials

- Incorrect manufacturing process

- Improper storage conditions

7. What are the safety precautions that must be taken when working with hardboard?

When working with hardboard, it is important to take the following safety precautions:

- Wear appropriate safety gear, such as gloves, safety glasses, and a dust mask.

- Be aware of the potential for sharp edges and splinters.

- Use caution when handling heavy pieces of hardboard.

- Store hardboard in a dry, well-ventilated area.

8. What are the environmental regulations that apply to hardboard production?

The environmental regulations that apply to hardboard production vary depending on the country or region in which the production takes place. However, some of the most common regulations include:

- Regulations on the use of hazardous chemicals

- Regulations on the emission of air pollutants

- Regulations on the disposal of wastewater

9. What are the trends in the hardboard industry?

The hardboard industry is currently experiencing a number of trends, including:

- The increasing use of hardboard in green building projects

- The development of new, innovative hardboard products

- The growing demand for hardboard in emerging markets

10. What are the challenges facing the hardboard industry?

The hardboard industry is currently facing a number of challenges, including:

- The rising cost of raw materials

- The increasing competition from other building materials

- The global economic downturn

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hardboard Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hardboard Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Hardboard Supervisor, you’ll oversee the daily operations of a manufacturing facility that produces hardboard, a type of fiberboard made from wood fibers. Your key responsibilities will include:

1. Production Management

Directing and coordinating production activities to ensure efficient and timely production of hardboard.

- Scheduling production runs and allocating resources to optimize production efficiency.

- Monitoring production processes to identify and address bottlenecks or inefficiencies, implementing corrective actions as needed.

2. Quality Assurance

Ensuring that hardboard products meet specified quality standards and customer requirements.

- Establishing and implementing quality control procedures to maintain product consistency.

- Inspecting finished products and conducting quality audits to verify compliance with standards.

3. Equipment Maintenance

Overseeing the maintenance and repair of production equipment to ensure optimal performance and minimize downtime.

- Coordinating with maintenance personnel to schedule and execute equipment maintenance and repairs.

- Monitoring equipment performance and identifying potential issues to prevent breakdowns.

4. Safety Management

Creating and maintaining a safe work environment for employees.

- Developing and implementing safety protocols and training programs for employees.

- Conducting safety inspections and audits to identify and mitigate potential hazards.

5. Team Management

Leading and motivating a team of production operators and support staff.

- Providing training and development opportunities to enhance employee skills and performance.

- Communicating effectively with team members and fostering a positive and productive work environment.

Interview Tips

To ace your interview for a Hardboard Supervisor position, consider these tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company and the hardboard industry. Research their products, processes, and market position. This shows that you’re genuinely interested in the role and have taken the time to understand the company’s business.

- Visit the company’s website to learn about their history, products, and operations.

- Read industry publications and articles to stay abreast of current trends and best practices.

2. Highlight Your Relevant Experience

Focus on your experience in production management, quality assurance, equipment maintenance, safety management, and team leadership. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Describe a specific project where you successfully improved production efficiency or reduced downtime.

- Provide examples of your quality control initiatives and how they resulted in improved product quality.

3. Emphasize Your Technical Skills

Hardboard production involves specialized equipment and processes. Highlight your technical skills and knowledge in areas such as fiberboard manufacturing, press operations, and finishing techniques.

- Discuss your experience with different types of hardboard presses, such as single-opening or continuous presses.

- Explain the curing and finishing processes involved in hardboard production.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare your answers accordingly. Some questions you may encounter include:

- “Describe your experience in managing a production team in a manufacturing environment.”

- “How would you ensure the quality and consistency of hardboard products?”

- “What measures would you implement to improve safety and minimize risks in a hardboard production facility?”

5. Be Confident and Enthusiastic

Confidence and enthusiasm are essential in any interview, but they are particularly important for a leadership role like Hardboard Supervisor. Show the interviewer that you are confident in your abilities and passionate about the industry. Maintain eye contact, speak clearly, and convey your excitement about the opportunity.

- Practice your answers to common interview questions to build confidence.

- Dress professionally and arrive on time for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hardboard Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!