Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hardener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

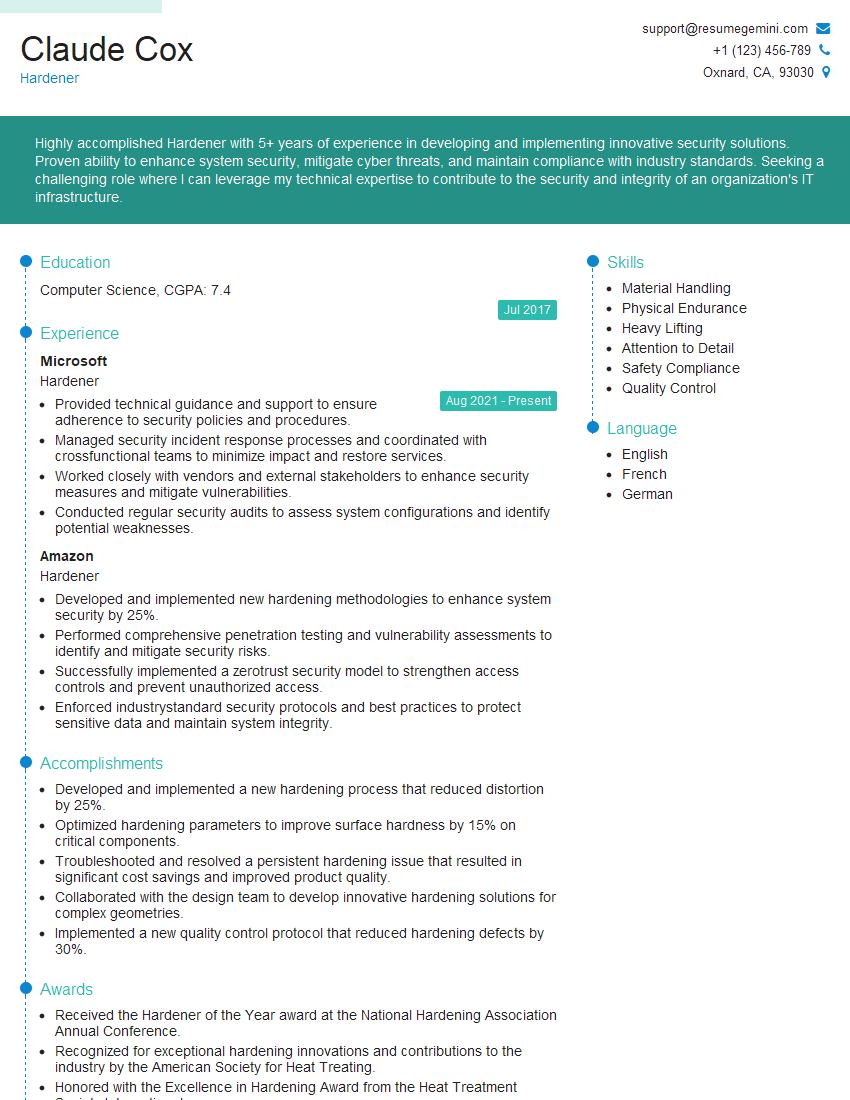

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hardener

1. What are the key responsibilities of a hardener?

As a hardener, my primary responsibilities include:

- Preparing and applying hardening agents to concrete surfaces

- Monitoring the curing process to ensure the desired hardness is achieved

- Inspecting hardened surfaces for any defects or imperfections

- Maintaining a safe and clean work environment

- Adhering to industry standards and regulations

2. What types of hardening agents are commonly used, and how do they differ?

Solvent-based Hardeners

- Highly volatile

- Penetrate deeply into the concrete

- Provide excellent abrasion resistance

Water-based Hardeners

- Less volatile than solvent-based

- Penetrate less deeply into the concrete

- Provide good abrasion resistance, but may need multiple applications

Lithium-based Hardeners

- Penetrate deeply into the concrete

- React with the concrete to form a harder surface

- Provide abrasion resistance and reduce dusting

3. What factors influence the curing time of a hardened surface?

The curing time of a hardened surface is influenced by several factors including:

- Type of hardening agent used

- Temperature and humidity of the environment

- Thickness of the hardened layer

- Condition of the concrete surface

- Ventilation of the area

4. How do you ensure that the hardened surface meets the desired specifications?

To ensure that the hardened surface meets the desired specifications, I follow these steps:

- Inspect the concrete surface for any defects or imperfections

- Prepare the surface according to the manufacturer’s instructions

- Apply the hardening agent evenly and thoroughly

- Monitor the curing process regularly

- Conduct hardness tests to verify the desired hardness is achieved

5. What are some common challenges you encounter as a hardener, and how do you overcome them?

Common challenges I encounter as a hardener include:

- Working in extreme weather conditions

- Dealing with difficult or uneven surfaces

- Ensuring that the hardened surface meets the desired specifications

- Protecting the environment from harmful chemicals

I overcome these challenges by:

- Wearing appropriate safety gear and following all safety procedures

- Using the right tools and equipment for the job

- Communicating effectively with colleagues and clients

- Staying up-to-date on industry best practices

6. What are some recent advancements in hardening techniques?

Recent advancements in hardening techniques include:

- The development of new and improved hardening agents

- The use of laser technology for hardening concrete surfaces

- The development of self-healing concrete

- The use of nanotechnology to improve the performance of hardened surfaces

7. How do you stay up-to-date on the latest hardening techniques?

I stay up-to-date on the latest hardening techniques by:

- Attending industry conferences and workshops

- Reading trade publications and journals

- Networking with other professionals in the field

- Conducting research and development

8. What is your experience with using power trowels and other equipment?

I have extensive experience using power trowels and other equipment, including:

- Ride-on power trowels

- Walk-behind power trowels

- Laser screeds

- Concrete grinders

- Concrete polishers

9. How do you ensure the safety of yourself and others while working as a hardener?

I ensure the safety of myself and others while working as a hardener by:

- Wearing appropriate safety gear, including a hard hat, safety glasses, gloves, and earplugs

- Following all safety procedures

- Being aware of my surroundings

- Communicating effectively with colleagues

- Reporting any unsafe conditions or practices

10. What is your availability to work overtime or on weekends?

I am available to work overtime or on weekends as needed. I understand that the construction industry often requires flexible work hours, and I am committed to meeting the needs of the project.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hardener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hardener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A hardener is responsible for a variety of tasks related to the hardening process in a manufacturing or industrial setting. These tasks may include:

1. Hardening and tempering of metals

This involves heating metals to a high temperature and then cooling them rapidly to increase their hardness and strength. Hardeners must have a good understanding of the different types of metals and the different hardening and tempering techniques that can be used.

2. Case hardening of metals

This involves hardening only the surface of a metal object, leaving the core softer and more ductile. Hardeners must be able to control the depth of the hardened case and the hardness of the surface.

3. Operating and maintaining hardening equipment

Hardeners must be able to operate and maintain a variety of hardening equipment, including furnaces, quenches, and tempering baths. They must also be able to troubleshoot and repair any problems that may occur.

4. Quality control

Hardeners must be able to inspect hardened parts to ensure that they meet the required specifications. They must also be able to identify and correct any defects that may occur.

Interview Tips

To ace an interview for a Hardener position, candidates should:

1. Research the company and the position

This will help you understand the company’s culture, values, and what they are looking for in a Hardener. You can find this information on the company’s website, LinkedIn page, or Glassdoor.

2. Practice your answers to common interview questions

This will help you feel more confident and prepared during the interview. Some common interview questions for Hardeners include:

- Tell me about your experience with hardening and tempering metals.

- What is case hardening? How is it different from traditional hardening?

- What types of hardening equipment are you familiar with?

- How do you ensure the quality of hardened parts?

3. Be prepared to talk about your skills and experience

Highlight your skills and experience that are relevant to the Hardener position. This may include your experience with hardening and tempering metals, case hardening, operating and maintaining hardening equipment, and quality control.

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic about the job and who are positive about their abilities. Show the interviewer that you are excited about the opportunity to work as a Hardener and that you are confident in your abilities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hardener, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hardener positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.