Feeling lost in a sea of interview questions? Landed that dream interview for Hardness Tester but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hardness Tester interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

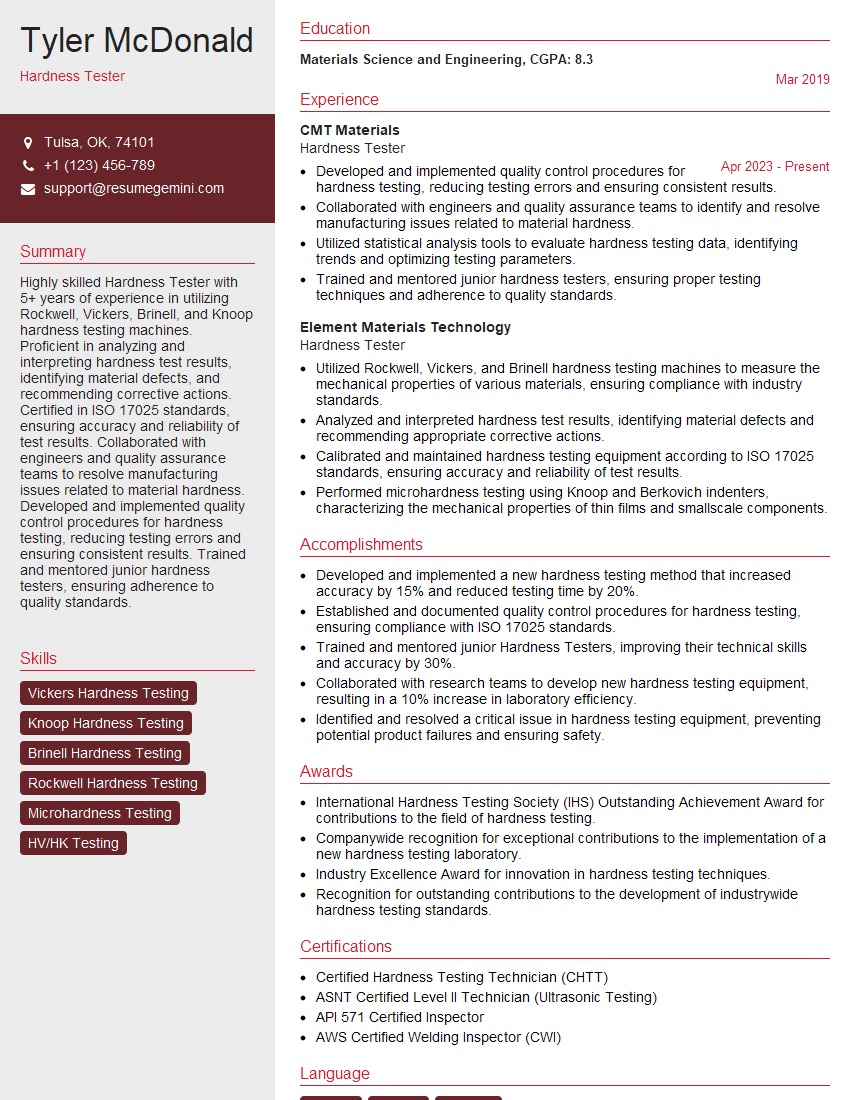

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hardness Tester

1. What are the different types of hardness tests and how do they work?

- Brinell Hardness Test: Measures the permanent deformation of a material by indenting it with a hardened steel ball under a specific load. The hardness is calculated by dividing the load by the surface area of the indentation.

- Rockwell Hardness Test: Measures the depth of penetration of a diamond or hardened steel ball into the material under a specific load. The hardness is determined by comparing the depth of penetration to a standard reference value.

- Vickers Hardness Test: Measures the diagonal length of the indentation made by a diamond pyramid indenter under a specific load. The hardness is calculated by dividing the load by the surface area of the indentation.

- Knoop Hardness Test: Similar to the Vickers test, but uses a diamond indenter with a different shape, resulting in a smaller and more elongated indentation.

- Microhardness Test: Uses smaller loads and indenters to measure the hardness of small samples or specific areas within a material.

2. What factors affect the accuracy of a hardness test?

Surface Preparation

- The surface must be smooth and free from defects to ensure accurate indentation.

Load and Indenter Type

- The load and indenter type must be appropriate for the material being tested to avoid material deformation or fracture.

Calibration and Verification

- Equipment should be regularly calibrated to ensure accuracy.

- Verification tests using reference blocks should be performed to confirm consistency.

Environmental Conditions

- Temperature, humidity, and vibrations can affect the accuracy of the test results.

3. What are the applications of hardness testing?

- Material Characterization: Determining the mechanical properties of materials.

- Quality Control: Ensuring that materials meet specified hardness requirements.

- Failure Analysis: Investigating the cause of material failures or damage.

- Research and Development: Developing and optimizing new materials.

- Heat Treatment Evaluation: Assessing the effectiveness of heat treatment processes.

4. How do you interpret and report hardness test results?

- Hardness Value: The numerical value obtained from the test, which represents the resistance to deformation.

- Scale and Units: Specify the hardness scale used (e.g., Brinell Hardness Number, Rockwell Hardness Number) and the corresponding units.

- Location and Orientation: Indicate the location and orientation of the test on the material.

- Uncertainty and Repeatability: Provide estimates of the uncertainty or repeatability of the test results.

- Interpretation: Compare the results to reference values or specifications to determine the acceptability of the material.

5. What are the advantages and limitations of different hardness testing methods?

Brinell Hardness Test

Advantages:- Large indentation, suitable for thick samples.

- Less sensitive to surface preparation than other methods.

- Cannot measure very hard materials.

- Leaves a permanent indentation.

Rockwell Hardness Test

Advantages:- Rapid and convenient to use.

- Wide range of scales available.

- Not suitable for small or thin samples.

- Surface preparation is critical for accurate results.

6. How do you choose the appropriate hardness test method for a specific application?

- Material Type: Consider the hardness range and material properties.

- Sample Size and Geometry: Choose a method suitable for the sample size and shape.

- Accuracy Requirements: Select a method that meets the required level of accuracy.

- Surface Condition: Determine if the surface preparation requirements of the method are compatible with the sample.

- Destructive vs. Non-Destructive: Consider if the indentation caused by the test is acceptable.

7. Explain the theory behind the Vickers Hardness Test.

- Indentation: A diamond pyramid indenter is pressed into the material under a specific load.

- Plastic Deformation: The material deforms plastically around the indenter, forming an indentation.

- Measurement: The diagonals of the indentation are measured using a microscope.

- Hardness Calculation: The Vickers Hardness Number (HV) is calculated using the formula HV = 1.8544 * (F/A), where F is the load and A is the surface area of the indentation.

8. How do you calibrate a Rockwell Hardness Tester?

- Test Block: Use a certified reference test block with a known hardness.

- Zero Adjustment: Set the zero point of the dial indicator by applying a minor load.

- Load Adjustment: Apply the specified major load and adjust the load indicator to match the reference value.

- Indenter Adjustment: Ensure that the indenter is properly aligned and seated.

- Verification: Repeat the test on multiple test blocks to verify calibration.

9. Describe the different hardness scales and their applications.

- Brinell Hardness Number (HB): Used for measuring the hardness of metals with a wide range of hardness levels.

- Rockwell Hardness Number (HR): Available in various scales (A, B, C, etc.) for different materials and hardness ranges.

- Vickers Hardness Number (HV): Suitable for measuring the hardness of very thin or small samples.

- Knoop Hardness Number (HK): Used for measuring the hardness of very hard materials.

- Shore Hardness: Used for measuring the hardness of elastomers and polymers.

10. What are the factors that can affect the hardness of a material?

- Alloy Composition: The presence of alloying elements can increase or decrease hardness.

- Heat Treatment: Processes such as annealing, quenching, and tempering can alter the hardness of a material.

- Grain Size: Smaller grain sizes generally result in higher hardness.

- Cold Working: Cold working processes, such as rolling or drawing, can increase hardness.

- Crystal Structure: Different crystal structures have different inherent hardness levels.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hardness Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hardness Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hardness Tester is responsible for ensuring the accuracy and reliability of hardness testing equipment and procedures within a manufacturing or quality control setting. The key job responsibilities include:

1. Setup and Calibration of Equipment

Sets up and calibrates hardness testing equipment, including Rockwell, Vickers, and Brinell testers, according to established standards and specifications.

- Performs routine maintenance and troubleshooting on equipment to ensure optimal performance.

- Develops and maintains calibration records and ensures traceability of calibration results.

2. Specimen Preparation and Testing

Prepares specimens for hardness testing, including grinding, polishing, and etching as required.

- Conducts hardness tests on a variety of materials, including metals, plastics, and ceramics.

- Records and interprets test results accurately and in accordance with established procedures.

3. Data Analysis and Reporting

Analyzes hardness test data and generates reports summarizing the results.

- Identifies trends and patterns in hardness data and provides recommendations for corrective actions.

- Collaborates with engineers, technicians, and quality managers to ensure the accuracy and reliability of hardness testing results.

4. Quality Assurance and Compliance

Participates in quality assurance programs and ensures compliance with industry standards and regulatory requirements.

- Maintains a clean and organized work area and follows safety protocols.

- Continuously improves processes and procedures to enhance the efficiency and accuracy of hardness testing.

Interview Tips

Preparing thoroughly for an interview is crucial for showcasing your skills and increasing your chances of success. Here are some tips to help you ace your interview for a Hardness Tester position:

1. Research the Company and Industry

Research the company’s history, products, and industry trends to demonstrate your interest and knowledge.

- Review the company website, LinkedIn page, and any relevant industry publications.

- This will help you understand the company’s culture, values, and business objectives.

2. Highlight Your Technical Skills

Emphasize your technical skills in hardness testing equipment, specimen preparation, and data analysis.

- Quantify your accomplishments by providing specific examples of projects or tasks where you successfully used these skills.

- Use technical terms and industry jargon appropriately to demonstrate your expertise.

3. Showcase Your Quality Assurance Experience

Highlight your experience in quality assurance and compliance to demonstrate your commitment to accuracy and reliability.

- Describe your involvement in developing and maintaining calibration records, as well as your understanding of industry standards.

- Share examples of how you have ensured the quality and integrity of hardness testing results.

4. Prepare for Common Interview Questions

Research common interview questions for Hardness Testers and practice your answers.

- Prepare answers to questions about your technical skills, experience with specific equipment, and quality assurance procedures.

- Practice articulating your strengths and how they align with the requirements of the role.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer during the interview to show your engagement and interest.

- Ask questions about the company’s quality assurance practices or industry trends in hardness testing.

- This demonstrates your curiosity and your desire to learn more about the role and the industry.

Next Step:

Now that you’re armed with the knowledge of Hardness Tester interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hardness Tester positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini