Are you gearing up for an interview for a Hardwood Sawyer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hardwood Sawyer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

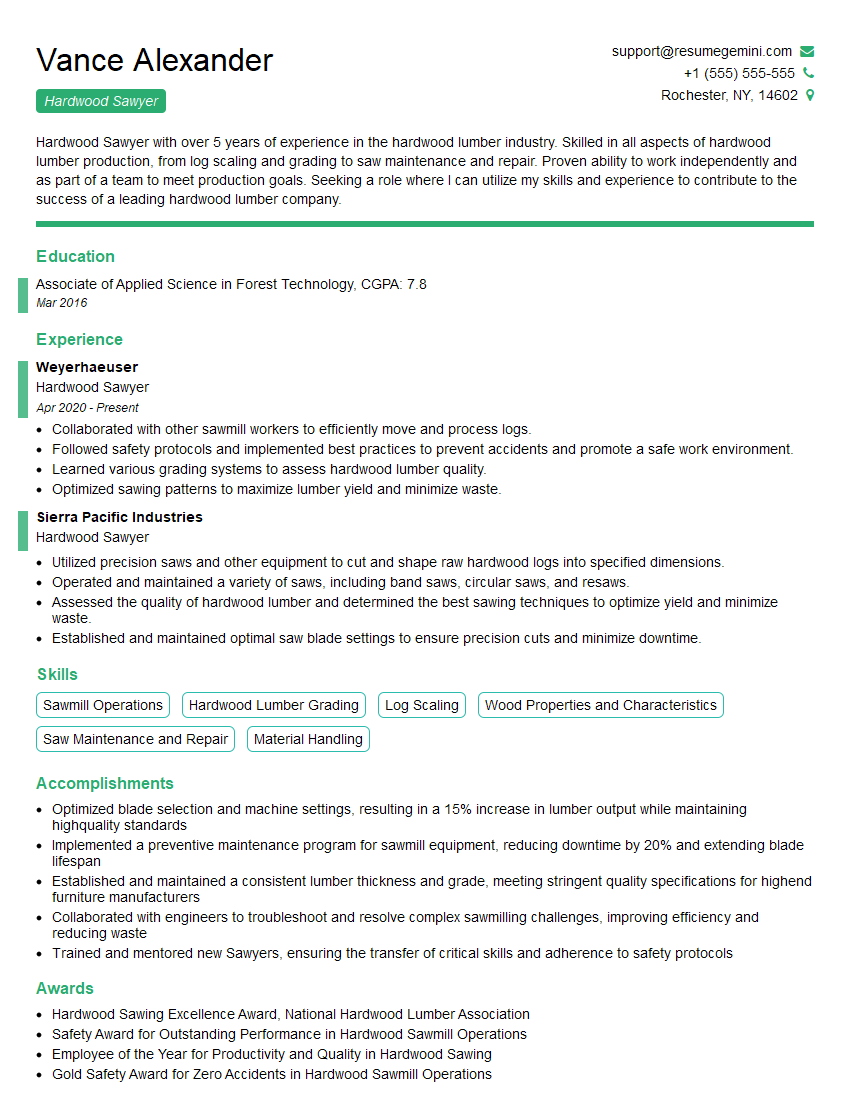

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hardwood Sawyer

1. How do you measure the moisture content of hardwood before sawing?

There are several methods to measure moisture content in hardwood before sawing:

- Moisture meter: A handheld device that measures the electrical resistance of the wood, which varies with moisture content.

- Oven method: Weighing the wood sample before and after drying in an oven at a specific temperature (e.g., 103°C) to calculate the moisture loss.

- Weight-to-volume ratio: Comparing the weight and volume of the wood sample to determine its density, which is affected by moisture content.

2. What are the key factors to consider when choosing a saw blade for hardwood sawing?

Blade Material

- High-carbon steel: Durable and affordable, suitable for general-purpose sawing.

- Carbide-tipped: Extremely hard and wear-resistant, ideal for cutting hardwoods with nails or embedded objects.

Tooth Design

- Triple-chip grind: Three cutting edges per tooth for smoother cuts and less tear-out.

- Alternate top bevel: Alternate teeth with angled tops to reduce feed force and create a cleaner finish.

Teeth Per Inch (TPI)

- Lower TPI (e.g., 6-8): For rough cutting and removing large amounts of material.

- Higher TPI (e.g., 12-16): For fine finishing and cleaner cuts with less sanding required.

3. How do you maintain and sharpen a circular saw blade for hardwood sawing?

Maintenance:

- Clean the blade regularly with a solvent to remove pitch and sawdust.

- Inspect the teeth for damage or dulling.

- Check the arbor hole for wear or looseness.

Sharpening:

- Use a sharpening jig or file guide to ensure proper tooth angles.

- File or grind the teeth to restore their sharp edges.

- Check the balance of the blade after sharpening to prevent vibration during operation.

4. What are the common defects in hardwood sawing and how can they be prevented?

Defects:- Warping and twisting: Caused by uneven drying or moisture content, can be minimized by proper drying techniques.

- Checking: Surface cracks due to rapid drying, can be prevented by controlled drying and minimizing surface exposure.

- Tear-out: Splintering or breakage of the wood fibers, can be reduced with sharp blades and proper feed rates.

5. What techniques can you use to improve the quality of finished hardwood surfaces?

- Select high-quality lumber: Look for straight-grained, knot-free pieces with minimal defects.

- Proper sawing: Use sharp blades and appropriate feed rates to minimize tear-out and splintering.

- Sanding: Start with coarse sandpaper and gradually move to finer grits to remove any imperfections and smooth the surface.

- Finishing: Apply appropriate finishes such as oil, varnish, or stain to protect and enhance the appearance of the wood.

6. What safety precautions should be taken when operating a hardwood saw?

- Wear appropriate safety gear: Safety glasses, earplugs, gloves, and a dust mask.

- Secure the wood: Use clamps or a vise to hold the workpiece firmly in place.

- Inspect the saw: Check for any loose parts, damaged blades, or electrical hazards before operating.

- Maintain a clean work area: Remove any tripping hazards or sawdust accumulation.

- Be aware of the blade’s path: Keep hands and body clear of the blade during operation.

7. What is the importance of maintaining proper feed rates when sawing hardwood?

Maintaining proper feed rates is crucial for several reasons:

- Safety: Excessive feed rates can cause the blade to stall or kickback, potentially leading to injuries.

- Blade life: Proper feed rates prevent the blade from overheating and becoming dull prematurely.

- Cut quality: Slower feed rates allow the blade to remove material more effectively, resulting in cleaner and smoother cuts.

- Machine performance: Maintaining appropriate feed rates ensures that the saw operates efficiently and without excessive strain.

8. How do you calculate the appropriate feed rate for a hardwood saw?

The appropriate feed rate depends on several factors, including:

- Wood type: Different hardwoods have varying densities and hardness, requiring different feed rates.

- Blade size and type: Larger blades typically require slower feed rates.

- Saw power: More powerful saws can handle higher feed rates.

- Blade sharpness: A sharp blade can cut more effectively at higher feed rates.

Refer to the manufacturer’s instructions or consult experienced professionals to determine the optimal feed rates for specific hardwood species and sawing conditions.

9. What are the potential hazards associated with working with hardwood dust?

- Respiratory problems: Inhaling hardwood dust can cause irritation, allergies, and in severe cases, respiratory diseases such as asthma.

- Skin irritation: Hardwood dust particles can cause skin rashes and itching, especially for individuals with sensitive skin.

- Eye irritation: Dust particles can get into the eyes and cause irritation, redness, and watering.

10. What measures can be taken to minimize the risks associated with hardwood dust exposure?

- Ventilation: Use proper ventilation systems to remove dust from the work area.

- Dust collection: Install dust collection devices on saws and sanders to capture dust at the source.

- Personal protective equipment: Wear respirators, gloves, and goggles to protect against dust exposure.

- Regular cleaning: Clean work surfaces and equipment regularly to prevent dust accumulation.

- Educate employees: Train workers on the hazards of hardwood dust and proper safety measures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hardwood Sawyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hardwood Sawyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hardwood Sawyers are responsible for operating and maintaining saws to cut hardwood logs into lumber or other products. Their responsibilities typically include:

1. Operating Saws

Hardwood Sawyers are responsible for operating a variety of saws, including head saws, band saws, and gang saws, to cut hardwood logs into lumber or other products. They must be able to adjust the saws to cut lumber to the desired thickness and width, and to maintain the saws in good working order.

- Operate head saws, band saws, and gang saws

- Adjust saws to cut lumber to desired thickness and width

- Maintain saws in good working order

2. Preparing Logs

Hardwood Sawyers are responsible for preparing logs for sawing. This may include removing bark and knots from the logs, and cutting the logs to the desired length. They must be able to identify the different types of hardwood trees and to determine the best way to cut each type of log.

- Remove bark and knots from logs

- Cut logs to desired length

- Identify different types of hardwood trees

- Determine the best way to cut each type of log

3. Monitoring Lumber

Hardwood Sawyers are responsible for monitoring the lumber produced by the saws to ensure that it meets the desired specifications. They must be able to identify defects in the lumber and to make adjustments to the saws to correct any problems.

- Monitor lumber produced by saws

- Ensure that lumber meets desired specifications

- Identify defects in lumber

- Make adjustments to saws to correct problems

4. Maintaining Equipment

Hardwood Sawyers are responsible for maintaining the saws and other equipment used in the sawing process. This may include cleaning the saws, oiling the bearings, and replacing worn parts. They must be able to troubleshoot problems with the equipment and to make minor repairs.

- Clean saws

- Oil bearings

- Replace worn parts

- Troubleshoot problems with equipment

- Make minor repairs

Interview Tips

Here are some tips to help you ace your interview for a Hardwood Sawyer position:

1. Research the company and the position

The more you know about the company and the position, the better prepared you’ll be to answer questions and demonstrate your interest in the role. Be sure to read the company website, LinkedIn page, and Glassdoor reviews. You should also research the specific duties and responsibilities of the Hardwood Sawyer position.

- Visit the company website

- Read LinkedIn page

- Check Glassdoor reviews

- Research the specific duties and responsibilities of the Hardwood Sawyer position

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice your answers to common interview questions

- Deliver them confidently and concisely

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Hardwood Sawyer. Be prepared to discuss your previous roles, the types of saws you’ve operated, and the different types of hardwood you’ve worked with. You should also be able to highlight your skills and abilities, such as your attention to detail, your ability to work independently, and your problem-solving skills.

- Discuss your previous roles

- Types of saws you’ve operated

- Different types of hardwood you’ve worked with

- Highlight your skills and abilities

4. Ask questions

Asking questions at the end of the interview shows that you’re interested in the position and that you’re taking the interview seriously. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include: “What are the most important qualities you’re looking for in a Hardwood Sawyer?” and “What are the opportunities for career advancement?”

- Ask questions at the end of the interview

- Shows that you’re interested in the position

- Taking the interview seriously

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hardwood Sawyer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!