Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Harness Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

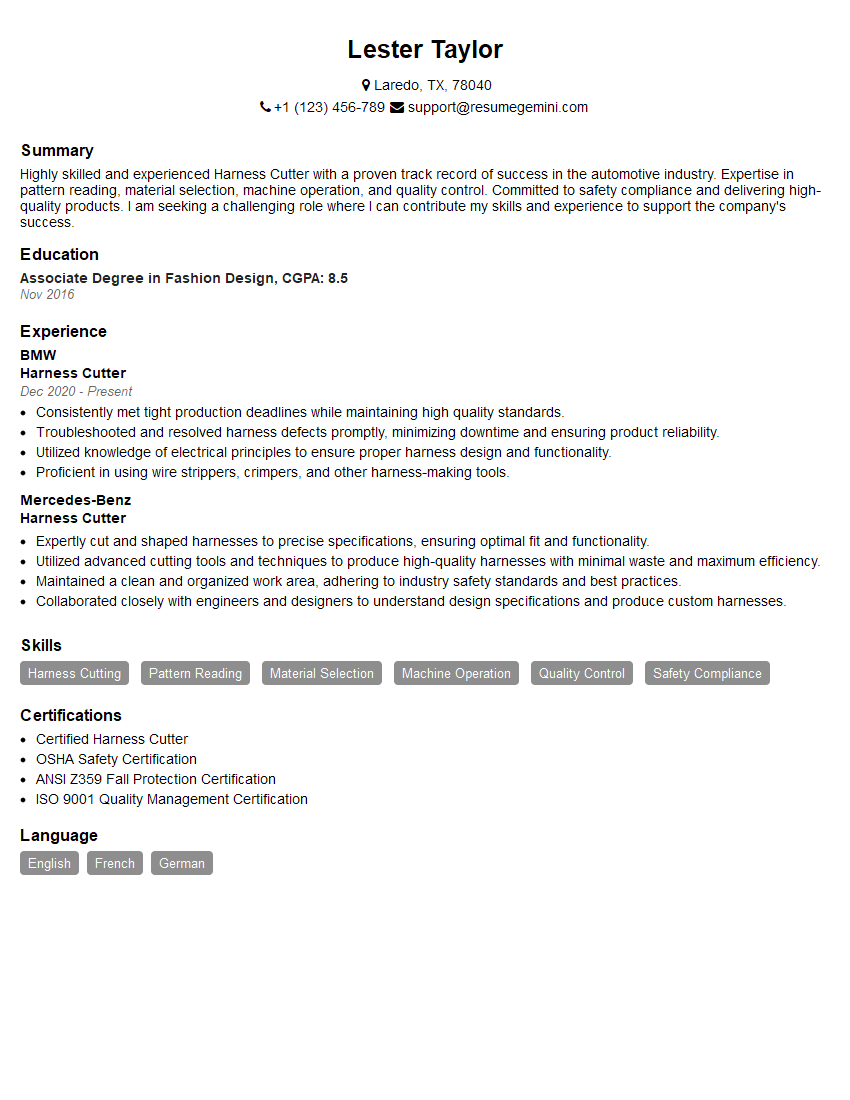

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Harness Cutter

1. What are the different types of materials used in harness making and their properties?

- Leather: Strong, durable, conformable to horse’s body, needs regular care.

- Nylon: Lightweight, strong, water-resistant, less durable than leather.

- Biothane: Strong, durable, water-resistant, easy to clean, not as conformable as leather.

- Rope: Durable, lightweight, can be used for halter ties or lead ropes.

2. Describe the steps involved in fitting a harness to a horse.

Measuring the Horse

- Measure the horse’s height, weight, and girth.

- Determine the type of harness needed (e.g., driving harness, riding harness).

Fitting the Harness

- Place the collar on the horse’s neck and adjust the buckles so that it fits snugly but not too tightly.

- Attach the traces to the collar and adjust the length so that the horse can move freely.

- Place the bridle on the horse’s head and adjust the bit so that it fits comfortably in the horse’s mouth.

- Attach the reins to the bridle and adjust the length so that the rider can comfortably control the horse.

3. What are the common problems that can occur with harness equipment and how to troubleshoot them?

- Broken straps: Replace the broken strap or have it repaired by a professional.

- Loose buckles: Tighten the buckles or replace them if they are damaged.

- Sore spots on the horse: Adjust the harness to eliminate pressure points or use padding to protect the horse’s skin.

- Harness slipping: Check the fit of the harness and make sure all straps are properly tightened.

- Horse refusing to wear the harness: Start by introducing the harness gradually and reward the horse for cooperation.

4. How do you maintain and care for harness equipment to ensure its longevity?

- Leather harness: Clean with a leather cleaner and conditioner regularly. Store in a cool, dry place.

- Nylon harness: Wash with mild soap and water. Air dry completely before storing.

- Biothane harness: Clean with a mild detergent and water. Air dry completely before storing.

- Metal parts: Oil or grease metal parts to prevent rust and corrosion.

- Store harness properly: Hang harness on a rack or store it in a box or bag to prevent damage.

5. What are the safety precautions to observe when working with harness equipment?

- Always inspect harness equipment before using it.

- Use proper lifting techniques to avoid injury.

- Wear gloves to protect your hands from sharp edges.

- Be aware of your surroundings and other people working with horses.

- Never leave horses unattended while wearing a harness.

6. What are the different types of harnesses used for different purposes (e.g., driving, riding, pulling)?

- Driving harness: Designed for pulling carts or carriages. Features a collar, traces, reins, and a bit.

- Riding harness: Designed for riding horses. Features a saddle, bridle, and reins.

- Pulling harness: Designed for pulling heavy loads. Features a collar, traces, and a breastplate.

- Pack harness: Designed for carrying loads on the back of a horse. Features a saddle, saddlebags, and a crupper.

7. What are the key features to consider when choosing the right harness for a specific horse and purpose?

- Size: The harness should fit the horse snugly without being too tight or too loose.

- Purpose: The harness should be designed for the intended use (e.g., driving, riding, pulling).

- Material: The harness should be made from durable, high-quality materials that are appropriate for the horse’s activity level.

- Comfort: The harness should be comfortable for the horse to wear and should not cause any pain or discomfort.

- Safety: The harness should be designed to protect the horse from injury in case of a fall or other accident.

8. Describe the process of custom fitting a harness to a horse.

- Measure the horse: Take accurate measurements of the horse’s height, weight, and girth.

- Select the appropriate harness: Choose a harness that is the correct size and design for the intended use.

- Fit the harness to the horse: Place the harness on the horse and adjust the straps and buckles until it fits snugly and comfortably.

- Test the fit: Have the horse wear the harness for a period of time to ensure that it is comfortable and does not cause any problems.

- Make final adjustments: Make any necessary adjustments to the harness to ensure a perfect fit.

9. What is the importance of proper harness maintenance and how often should it be checked?

- Safety: Regular maintenance helps to ensure that the harness is in good condition and safe to use.

- Durability: Proper maintenance extends the lifespan of the harness.

- Performance: A well-maintained harness will perform better and provide a more comfortable fit for the horse.

- Frequency: Harness should be checked and maintained regularly, especially before and after each use.

10. What are the common materials used for harness repair and their advantages and disadvantages?

- Leather: Durable, strong, conformable, but requires regular maintenance.

- Nylon: Lightweight, strong, water-resistant, but less durable than leather.

- Biothane: Strong, durable, water-resistant, easy to clean, but not as conformable as leather.

- Metal: Strong, durable, but can rust or corrode.

- Thread: Used to stitch or repair harness, must be strong and durable.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Harness Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Harness Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Harness Cutter, as a key member of a production team, is responsible for overseeing the production of harnesses, a crucial component connecting electrical and mechanical systems. This highly skilled professional collaborates with engineers, assemblers, and quality control inspectors to ensure the efficient and precise production of harnesses.

1. Harness Assembly

The Harness Cutter is directly involved in the assembly process, using cutting-edge equipment and techniques. Their responsibilities include:

- Precisely cutting wires and cables to specified lengths, ensuring optimal performance and durability.

- Stripping insulation from wires to prepare them for connection, maintaining high electrical conductivity.

- Terminating wires using appropriate connectors, adhering to industry standards and specifications.

2. Quality Control

The Harness Cutter is committed to maintaining the highest standards of quality and accuracy. Their role involves:

- Thoroughly inspecting completed harnesses for any defects or inconsistencies, ensuring flawless connections

- Verifying the electrical continuity of harnesses through rigorous testing, guaranteeing proper functionality.

- Collaborating with quality control inspectors to address any quality concerns, maintaining a commitment to excellence.

3. Production Optimization

To maximize productivity and efficiency, the Harness Cutter actively engages in:

- Analyzing production processes to identify areas for improvement, promoting innovation and streamlining.

- Working closely with engineers to optimize harness designs, reducing material waste and enhancing performance.

- Training and mentoring new team members, fostering a culture of expertise and professionalism.

4. Safety and Compliance

The Harness Cutter is committed to maintaining a safe and compliant work environment, ensuring:

- Strict adherence to safety protocols, minimizing risks and promoting a healthy workplace.

- Compliance with relevant industry regulations and standards, maintaining ethical and legal integrity.

- Active participation in safety training programs, staying abreast of best practices and advancements.

Interview Tips

To excel in a Harness Cutter interview, it’s crucial to prepare meticulously. Here are some tips to help you ace the interview:

1. Research the Company and Industry:

Demonstrate your interest and enthusiasm by researching the company, its products or services, and the harness manufacturing industry. Understanding their values, mission, and market position will show your dedication and eagerness to contribute.

- Example Outline:

I took the time to learn about your company’s commitment to innovation in the automotive industry. Your focus on sustainability and quality manufacturing aligns perfectly with my values and career goals.

2. Highlight Your Skills and Experience:

Confidently present your relevant skills and experience that make you an ideal candidate for the Harness Cutter position. Emphasize your expertise in harness assembly, quality control, and production optimization.

- Example Outline:

In my previous role, I consistently exceeded production targets while maintaining a 99% accuracy rate, ensuring the highest quality standards.

3. Prepare for Technical Questions:

Expect technical questions related to harness cutting techniques, equipment operation, and quality control procedures. Brush up on your knowledge of wire gauges, insulation types, and termination methods.

- Example Outline:

I’m familiar with various cutting and stripping tools, including precision cutters, wire strippers, and crimping pliers. I also have a strong understanding of electrical continuity testing using multimeters.

4. Demonstrate Your Problem-Solving Ability:

Interviewers may present you with hypothetical scenarios to assess your problem-solving skills. Think critically about potential challenges in harness production and articulate your approach to resolving them.

- Example Outline:

If I encounter a defective component during the assembly process, I would promptly isolate the issue, determine the root cause, and take corrective action to prevent future occurrences.

5. Practice and Stay Calm:

Practice your answers to common interview questions and prepare thoughtful questions to ask the interviewer. Staying calm and confident during the interview will help you make a positive impression and showcase your professionalism.

- Example Outline:

I’ve prepared by practicing my answers to questions about my experience, skills, and problem-solving approach. I’m confident that I can clearly articulate my qualifications and demonstrate my enthusiasm for the Harness Cutter role.

Next Step:

Now that you’re armed with the knowledge of Harness Cutter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Harness Cutter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini