Are you gearing up for an interview for a Harness Rigger position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Harness Rigger and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

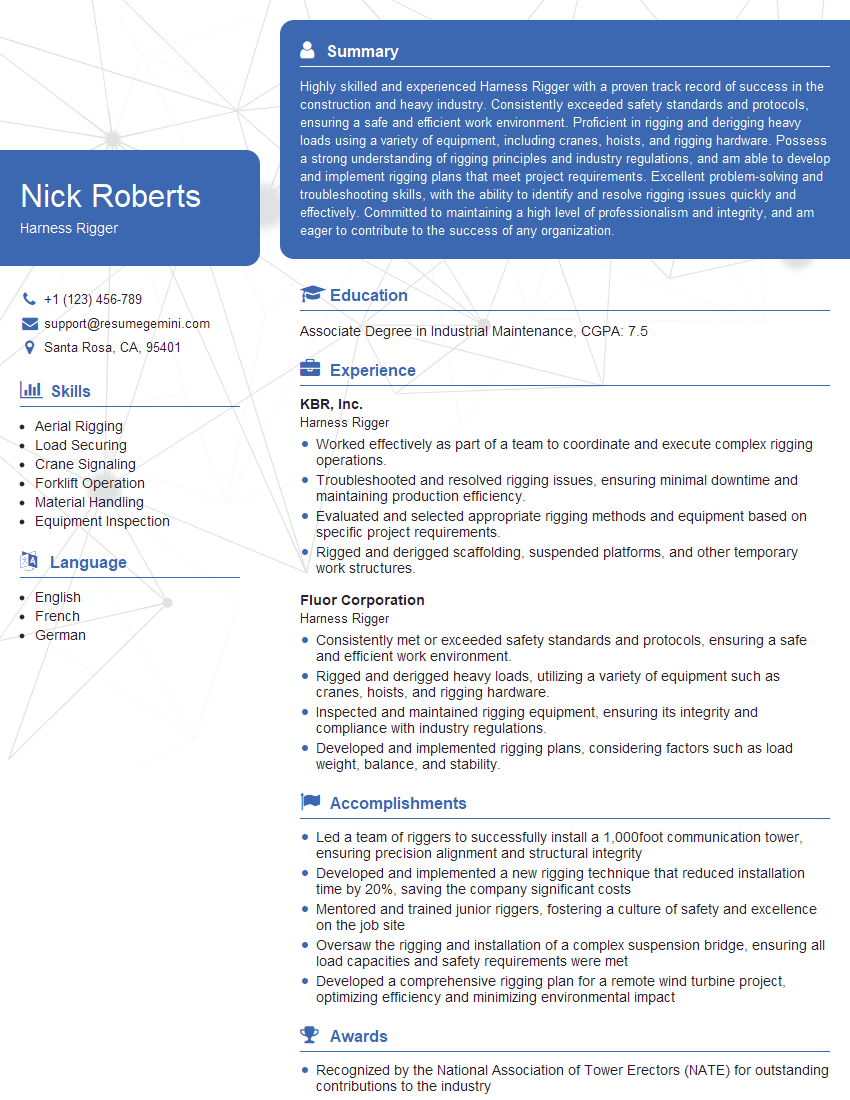

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Harness Rigger

1. What is the primary responsibility of a Harness Rigger?

The primary responsibility of a Harness Rigger is to ensure the safe and efficient use of rigging equipment, including the inspection, assembly, disassembly, maintenance, and certification of harnesses, slings, ropes, and other lifting devices.

2. Describe the types of knots and hitches used in rigging operations.

Common Knots

- Bowline knot: Forms a non-slip loop at the end of a rope

- Figure-eight knot: Used to secure a rope to itself or to another rope

- Square knot: Joining two ropes together

Common Hitches

- Clove hitch: Securing a rope to a pole or bar

- Sheet bend: Connecting a rope to a larger rope or ring

- Becket bend: Joining a rope to a loop

3. Explain the importance of load calculation in rigging operations.

Load calculation determines the maximum weight that a rigging system can safely support. It involves considering factors such as the weight of the load, the angle of the lift, and the capacity of the equipment being used. Proper load calculation ensures that the rigging system does not exceed its limits, preventing accidents and damage.

4. What are the different inspection techniques used for rigging equipment?

Rigging equipment is regularly inspected to ensure its integrity and safety. Inspection techniques include:

- Visual inspection: Checking for any visible damage or wear

- Magnetic particle inspection: Detecting cracks and other defects

- Ultrasonic testing: Identifying internal flaws or defects

5. How do you maintain and store rigging equipment properly?

Proper maintenance and storage extend the lifespan and ensure the safety of rigging equipment.

- Cleaning: Rigging equipment should be cleaned regularly to remove dirt, debris, and chemicals

- Lubrication: Moving parts of rigging equipment should be lubricated to reduce wear and corrosion

- Storage: Equipment should be stored in a dry, well-ventilated area, protected from moisture and sunlight

6. What are the safety precautions you take when working with rigging equipment?

Safety precautions for working with rigging equipment include:

- Wear appropriate PPE: Hard hat, safety glasses, gloves

- Inspect the equipment thoroughly before use

- Never exceed the rated capacity of the equipment

- Use proper lifting techniques and avoid sudden jerks or movements

- Be aware of your surroundings and potential hazards

7. Describe the different types of lifting slings and their applications.

Types of Lifting Slings

- Web slings: Made from synthetic materials, offer flexibility and are lightweight

- Chain slings: Made from alloy steel links, provide strength and durability

- Wire rope slings: Made from high-tensile wire ropes, ideal for heavy loads

- Round slings: Made from endless round slings, offer easy handling and less abrasion

Applications depend on factors such as load weight, shape, and the environment.

8. Explain the principles of selecting the correct lifting equipment for a given task.

Selecting the correct lifting equipment involves considering the following factors:

- Weight and shape of the load

- Height and angle of the lift

- Environmental conditions

- Safety regulations and standards

The goal is to choose equipment that is both safe and efficient for the specific task.

9. What are your experiences in working with different types of machinery and equipment?

As a Harness Rigger, I have worked with a wide range of machinery and equipment, including cranes, hoists, winches, forklifts, and various types of lifting devices. I am proficient in operating these machines safely and efficiently, ensuring the smooth and controlled movement of loads.

10. Describe a situation where you encountered a problem during a rigging operation and how you resolved it.

Once, while working on a construction site, I encountered a situation where a load was not balanced properly and began to sway dangerously during a lift. To resolve the issue, I quickly assessed the situation and adjusted the rigging points to create a more stable and secure lift. By taking prompt and decisive action, I prevented a potential accident and ensured the safety of the crew and equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Harness Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Harness Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Harness Rigger is accountable for assembling and maintaining safety harnesses, lanyards, and related equipment used for fall protection in industrial and construction settings. The role demands a thorough understanding of rigging techniques, safety regulations, and industry best practices to ensure the safety of workers at heights.

1. Equipment Inspection and Maintenance

Harness Riggers regularly inspect and maintain safety equipment, including harnesses, lanyards, lifelines, and other rigging components. They meticulously examine these items for damage, wear, or defects that could compromise safety. Additionally, they ensure that equipment conforms to industry standards and regulations.

2. Fall Protection Planning and Implementation

Riggers play a crucial role in developing and implementing fall protection plans. They assess work sites, identify potential hazards, and select appropriate fall protection systems. They also determine the correct positioning of anchors, lifelines, and other equipment to ensure the effectiveness of the fall protection plan.

3. Training and Education

Harness Riggers are responsible for training workers on the proper use and maintenance of safety harnesses and fall protection equipment. They provide instruction on donning, adjusting, and inspecting harnesses, as well as on safe work practices and emergency procedures. They also stay up-to-date on industry best practices, regulations, and new technologies related to fall protection.

4. Hazard Identification and Mitigation

Riggers are responsible for identifying and mitigating hazards that could lead to falls. They conduct thorough site inspections, assess potential risks, and make recommendations for corrective actions. They also work closely with other safety professionals and supervisors to ensure that work areas are safe and comply with regulations.

Interview Tips

Preparing for a Harness Rigger interview requires a combination of technical knowledge and an understanding of safety best practices. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Familiarize yourself with the company’s safety policies, industry regulations, and best practices. This will demonstrate your interest in the role and your commitment to safety.

2. Highlight Your Expertise

Emphasize your knowledge of rigging techniques, fall protection systems, and safety standards. Provide specific examples of your experience in inspecting, maintaining, and implementing fall protection plans.

3. Showcase Your Safety Mindset

Convey your passion for safety and your commitment to ensuring the well-being of workers. Discuss your understanding of the importance of fall protection and your role in mitigating risks.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to harness rigging, such as:

- What are the key steps involved in inspecting a safety harness?

- How do you determine the appropriate fall protection system for a specific work site?

- Describe a time when you identified and mitigated a fall hazard.

5. Seek Feedback

After your interview, ask for feedback to identify areas where you can improve your preparation for future interviews.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Harness Rigger interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!