Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hat Block Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

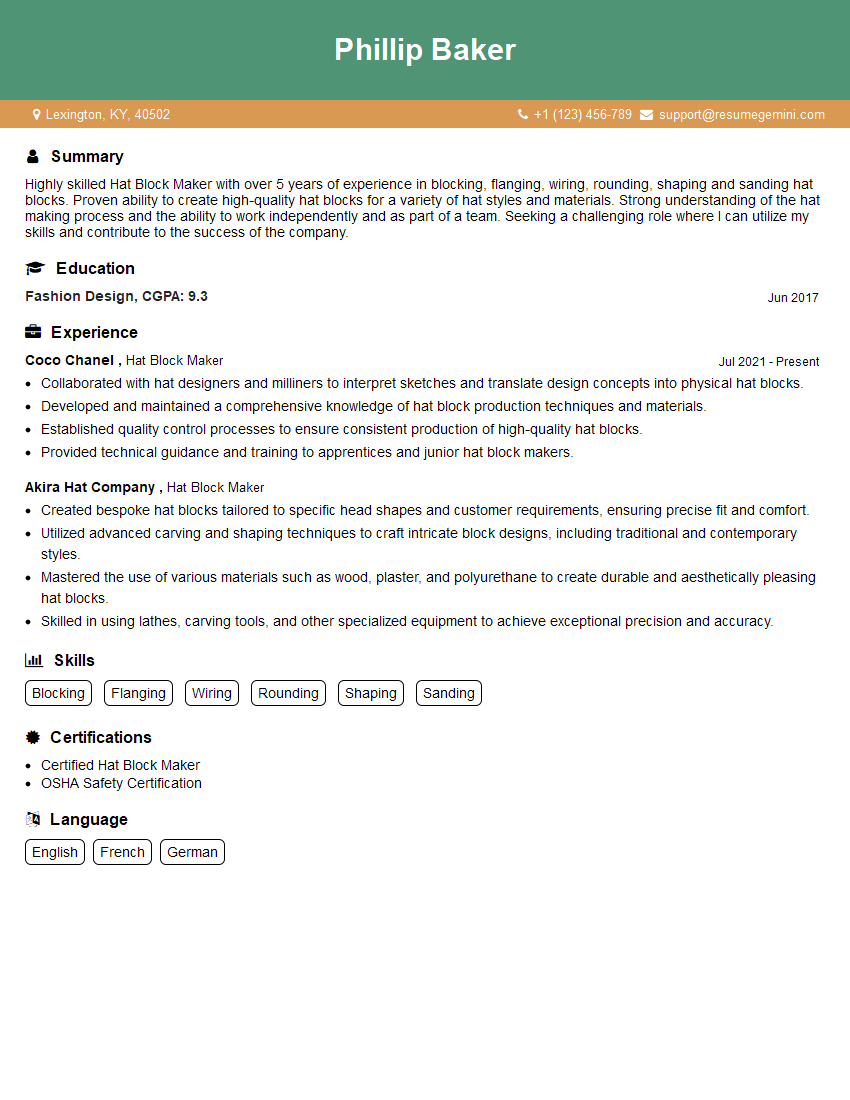

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hat Block Maker

1. What is the primary material used in hat block making, and how is it prepared?

- The primary material is wood, usually seasoned birch or maple.

- The wood is cut into blocks and then shaped using a variety of tools, including lathes, saws, and sanders.

- The blocks are then sanded smooth and sealed to protect them from moisture.

2. Describe the process of shaping a hat block by hand.

Using a Lathe

- The block is mounted on a lathe and rotated while a cutting tool is used to shape the exterior.

- This process requires skill and experience to achieve the desired shape and symmetry.

Using Hand Tools

- The block can also be shaped using hand tools such as gouges, chisels, and rasps.

- This method is more time-consuming but allows for greater precision and detail.

3. What factors should be considered when selecting wood for hat block making?

- The type of wood: Birch and maple are commonly used due to their strength, durability, and ability to hold detail.

- Grain direction: The direction of the wood grain affects the strength and stability of the block.

- Moisture content: The wood should be properly seasoned to prevent warping or cracking.

- Knots and defects: Avoid wood with excessive knots or defects that could weaken the block.

4. What are the different types of hat block finishes, and how do they affect the appearance and durability of the block?

- Lacquer: A clear finish that provides a glossy, protective layer.

- Shellac: A natural finish that gives a warm, amber tone and protects the wood from moisture.

- Oil: A penetrating finish that enhances the wood’s grain and provides some protection.

- Wax: A traditional finish that creates a matte surface and imparts a slight water resistance.

5. How do you ensure the accuracy and precision of the hat blocks you produce?

- Using precise measuring tools and templates.

- Employing calibrated equipment such as lathes and sanding machines.

- Regularly checking and adjusting tools to maintain accuracy.

- Inspecting each block thoroughly before finishing to ensure it meets specifications.

6. What are the common challenges faced in hat block making, and how do you overcome them?

- Warpage: Controlling the moisture content of the wood and using proper storage techniques.

- Splitting: Selecting high-quality wood with minimal defects and using proper grain orientation.

- Achieving precise shapes: Employing skilled craftsmanship, using templates, and employing specialized shaping tools.

- Maintaining durability: Using durable wood species, applying protective finishes, and storing blocks in controlled environments.

7. Describe the process of creating a hat block from a customer’s design or specification.

- Consulting with the customer to understand their design requirements.

- Translating the design into technical specifications, including measurements and shape details.

- Selecting appropriate wood and preparing the block.

- Shaping the block using a combination of hand tools and machinery.

- Applying any necessary finishes or modifications.

8. What are the safety precautions that need to be observed when working with hat block making equipment?

- Wearing appropriate safety gear, including gloves, eye protection, and earplugs.

- Keeping the work area clean and free of debris.

- Using sharp tools properly and storing them safely.

- Inspecting equipment regularly for any damage or malfunctions.

9. How do you stay up-to-date with the latest techniques and materials used in hat block making?

- Attending industry workshops and conferences.

- Reading trade publications and online resources.

- Networking with other hat block makers and professionals.

- Experimenting with new materials and techniques to improve craft.

10. Describe a particularly challenging or memorable project you worked on as a Hat Block Maker.

- Explain the unique challenges and requirements of the project.

- Highlight the skills and techniques used to overcome these challenges.

- Describe the outcome of the project and any lessons learned.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hat Block Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hat Block Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hat Block Maker is a skilled artisan responsible for crafting the wooden blocks or molds used in the creation of hats. They work closely with designers and milliners to ensure the accuracy and quality of the blocks, which are essential for producing well-fitting and aesthetically pleasing hats.

1. Block Carving

Hat Block Makers use specialized tools and techniques to carve and shape wooden blocks into the desired hat shape. They must have a deep understanding of hat design and anatomy to ensure that the blocks are anatomically correct and produce hats that fit comfortably.

- Carve and shape wooden blocks using hand tools, such as gouges, chisels, and rasps.

- Sand and finish blocks to achieve the desired smoothness and shape.

2. Block Design

Hat Block Makers collaborate with designers and milliners to translate hat designs into functional blocks. They must have a strong understanding of hat construction techniques to ensure that the blocks produce hats that meet the desired specifications.

- Interpret hat designs and translate them into block designs.

- Create and modify block designs to achieve the desired hat shape and fit.

3. Quality Control

Hat Block Makers are responsible for ensuring the accuracy and quality of the blocks they create. They must inspect blocks for any defects or imperfections and make necessary adjustments to ensure that they meet the required standards.

- Inspect blocks for accuracy, dimensions, and shape.

- Identify and correct any defects or imperfections in blocks.

4. Communication and Collaboration

Hat Block Makers work closely with designers, milliners, and other members of the hat-making team. They must have strong communication and collaboration skills to ensure that the blocks meet the desired requirements.

- Communicate with designers and milliners to understand hat design specifications.

- Collaborate with other team members to ensure smooth production processes.

Interview Tips

Preparing for an interview for a Hat Block Maker position requires thorough research, practice, and a deep understanding of the role. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Familiarize yourself with the hat-making industry, the company you’re interviewing with, and their products or services. This knowledge will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Practice Your Skills

Hat Block Making is a highly skilled craft. Showcase your abilities by bringing a portfolio of your work to the interview. If possible, demonstrate your carving and shaping techniques during the interview.

- Practice carving and shaping techniques to demonstrate your proficiency.

- Prepare a portfolio showcasing your best work.

3. Prepare for Common Interview Questions

Prepare for common interview questions related to your skills, experience, and the industry. Research hat-making techniques, block design principles, and quality control measures.

- Practice answering questions about your block carving and design skills.

- Research industry trends and advancements.

4. Be Enthusiastic and Passionate

Hat Block Making requires passion and dedication. Convey your enthusiasm for the craft and your desire to contribute to the team. Highlight your love for hat-making and your commitment to excellence.

- Share your experiences and knowledge in the industry.

- Express your eagerness to learn and grow within the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hat Block Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.