Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hat Stock Laminating Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

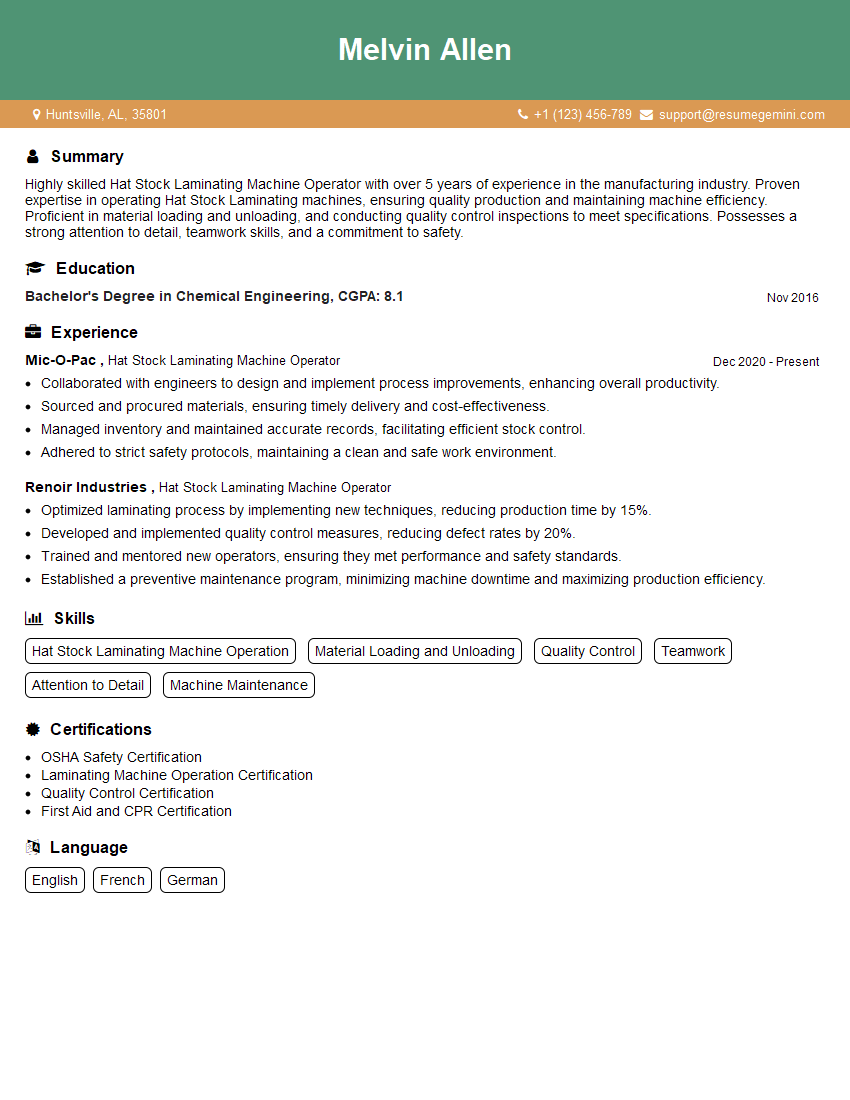

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hat Stock Laminating Machine Operator

1. Explain the process of laminating hat stock paper?

The process of laminating hat stock paper involves several steps:

- Prepare the adhesive: Apply a thin layer of adhesive to the back of the hat stock paper using a brush, roller, or sprayer.

- Align the fabric: Place the fabric on top of the adhesive-coated paper, ensuring that it is aligned properly.

- Press the fabric: Use a laminating machine or hand roller to apply pressure on the fabric, ensuring that it bonds firmly with the paper.

- Trim the excess fabric: Use a sharp knife or scissors to cut away any excess fabric around the edges.

- Cure the adhesive: Allow the adhesive to cure according to the manufacturer’s instructions. This may involve leaving the laminated piece at room temperature or applying heat.

2. What are the different types of laminating machines used for hat stock?

Manual Laminating Machines

- Require manual application of pressure using levers or rollers.

- Suitable for small-scale operations or prototyping.

Semi-Automatic Laminating Machines

- Combine manual feeding with automated pressure application.

- Offer increased efficiency compared to manual machines.

Automatic Laminating Machines

- Fully automated, handling both feeding and pressure application.

- Capable of high-volume production.

3. How do you maintain and troubleshoot a hat stock laminating machine?

Regular maintenance is crucial to ensure optimal performance and prevent breakdowns:

- Clean the machine: Regularly remove any adhesive residue, fabric scraps, or dust from the machine’s rollers, platens, and other components.

- Lubricate the machine: Apply lubricant to moving parts as per the manufacturer’s instructions.

- Calibrate the machine: Ensure that the pressure and temperature settings are calibrated correctly.

- Troubleshooting: If the machine is not functioning properly, identify the issue and consult the manufacturer’s manual or contact a qualified technician.

4. What are the safety precautions to be taken while operating a hat stock laminating machine?

- Wear appropriate safety gear: Wear safety glasses, gloves, and protective clothing to prevent exposure to adhesives and other materials.

- Keep the work area clean: Avoid slips and falls by maintaining a clean and organized work environment.

- Be aware of pinch points: Pay attention to areas where fingers or other body parts could get caught, such as the machine’s rollers.

- Follow operating instructions: Always follow the manufacturer’s instructions for safe operation of the machine.

5. How do you ensure the quality of laminated hat stock?

- Inspect the materials: Check the quality of the hat stock paper and fabric before laminating.

- Control the lamination process: Monitor the temperature, pressure, and adhesive application to ensure optimal bonding.

- Inspect the finished product: Examine the laminated hat stock for any defects, such as bubbles, wrinkles, or delamination.

- Establish quality control standards: Define clear specifications for acceptable quality and implement a system to monitor and maintain these standards.

6. What is the difference between hot and cold laminating for hat stock?

Hot Laminating

- Uses heat and pressure to bond the materials.

- Produces a durable and water-resistant bond.

- Requires specialized equipment and materials.

Cold Laminating

- Uses pressure alone to bond the materials.

- Creates a less durable bond than hot laminating.

- Requires less specialized equipment.

7. What types of adhesives are used in hat stock lamination?

- Water-based adhesives: Environmentally friendly, easy to clean up, but may require longer drying times.

- Solvent-based adhesives: Strong and fast-setting, but may emit harmful fumes.

- Hot-melt adhesives: Applied as hot, molten liquid, providing a strong and heat-resistant bond.

8. How do you handle and store laminated hat stock?

- Handle with care: Avoid bending or creasing the laminated hat stock.

- Store in a dry environment: Protect the laminated hat stock from moisture and humidity.

- Use protective materials: Store the laminated hat stock between layers of paper or plastic to prevent scratches.

9. What is the typical production rate for a hat stock laminating machine?

The production rate depends on factors such as the machine’s speed, the size of the hat stock, and the type of adhesive used.

For example, a semi-automatic machine may produce around 1000 laminated hat stocks per hour, while a fully automatic machine can produce up to 2500 laminated hat stocks per hour.

10. What are the common challenges faced in hat stock laminating and how can they be overcome?

- Bubbles and wrinkles: Ensure proper alignment, apply even pressure, and use a suitable adhesive.

- Delamination: Check the compatibility of the materials, use the correct adhesive, and control the lamination process.

- Machine malfunctions: Follow regular maintenance schedules, troubleshoot issues promptly, and contact a qualified technician if necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hat Stock Laminating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hat Stock Laminating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hat Stock Laminating Machine Operators have the primary responsibility to operate laminating machinery to join two or more layers of hat stock material together, ensuring proper bonding and alignment.

1. Machine Setup and Operation

Duties involve setting up and operating laminating machines according to specified parameters, including temperature, pressure, and speed.

- Configure machine settings and select appropriate adhesives for specific hat stock materials.

- Thread hat stock material through the laminating machine, ensuring proper alignment and tension.

- Monitor machine operation, adjust settings as needed, and perform routine maintenance to ensure optimal performance.

2. Quality Control and Inspection

Inspect laminated hat stock to ensure it meets quality standards, including proper adhesion, thickness, and appearance.

- Examine laminated materials for defects such as bubbles, wrinkles, or delamination.

- Conduct physical and dimensional checks to ensure compliance with specifications.

- Reject non-conforming materials and report any quality issues to supervisors.

3. Production and Efficiency

Maintain high levels of productivity and efficiency in the laminating process.

- Optimize machine settings and operating procedures to maximize output.

- Troubleshoot and resolve production issues promptly to minimize downtime.

- Adhere to safety guidelines and maintain a clean and organized work area.

4. Material Handling and Storage

Handle and store hat stock materials and adhesives safely and efficiently.

- Load and unload hat stock rolls onto and off of laminating machines.

- Maintain inventory of adhesives and other supplies.

- Follow proper storage procedures to ensure the integrity of materials.

Interview Tips

To ace an interview for a Hat Stock Laminating Machine Operator position, it’s essential to prepare thoroughly and highlight your relevant skills and experience.

1. Research the Company and Role

Familiarize yourself with the company’s background, products, and industry standing. Understand the specific requirements of the Hat Stock Laminating Machine Operator role.

- Visit the company’s website and social media pages.

- Read industry publications and articles to gain insights into the field.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating laminating machinery, including specific models and materials. Showcase your understanding of adhesive properties and bonding techniques.

- Quantify your accomplishments, using specific metrics and examples.

- Demonstrate your ability to troubleshoot and resolve production issues.

3. Prepare for Technical Questions

Expect technical questions related to laminating processes, machine operation, and quality control. Prepare for questions on troubleshooting, safety procedures, and maintenance.

- Review the principles of laminating and bonding.

- Study the operating manuals for common laminating machines.

4. Practice Your Answers

Rehearse your answers to common interview questions. This will help you articulate your skills and experience clearly and confidently.

- Use the STAR method (Situation-Task-Action-Result) to structure your answers.

- Seek feedback from a mentor or career counselor to improve your interview skills.

5. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Maintain a positive and enthusiastic attitude throughout the process.

- Show interest in the company and the position.

- Ask thoughtful questions to demonstrate your engagement and curiosity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hat Stock Laminating Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.