Feeling lost in a sea of interview questions? Landed that dream interview for Hazard Analysis and Critical Control Point Coordinator (HACCP Coordinator) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hazard Analysis and Critical Control Point Coordinator (HACCP Coordinator) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

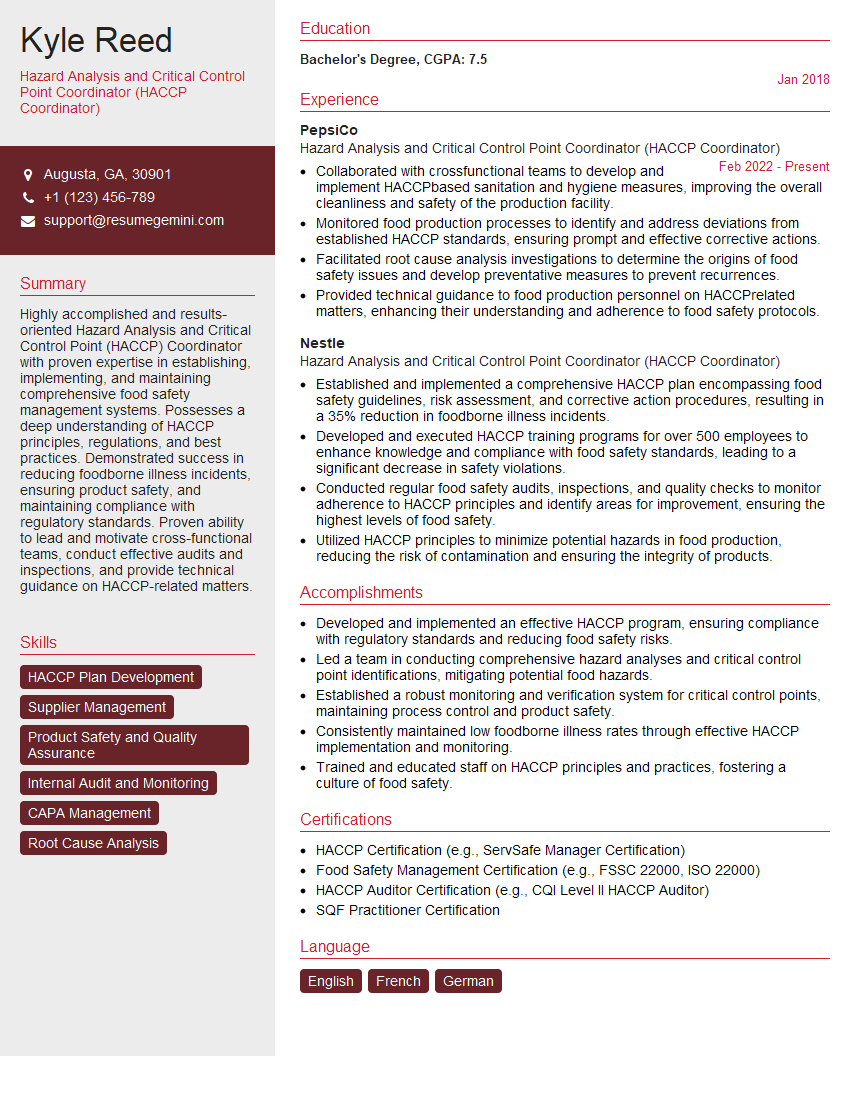

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hazard Analysis and Critical Control Point Coordinator (HACCP Coordinator)

1. Explain the seven principles of HACCP and how you would apply them in a food manufacturing environment?

The seven principles of HACCP are:

- Conduct a hazard analysis.

- Determine the critical control points (CCPs).

- Establish critical limits for each CCP.

- Establish monitoring procedures for each CCP.

- Establish corrective actions for each CCP.

- Establish verification procedures.

- Establish documentation and record-keeping procedures.

In a food manufacturing environment, I would apply the seven principles of HACCP by:

- Conducting a hazard analysis to identify the potential hazards that could occur during the production process.

- Determining the CCPs, which are the points in the process where the hazards can be controlled.

- Establishing critical limits for each CCP, which are the maximum or minimum values that the CCP must meet to prevent the hazard from occurring.

- Establishing monitoring procedures for each CCP to ensure that the CCPs are operating within the critical limits.

- Establishing corrective actions for each CCP to be taken if the CCPs deviate from the critical limits.

- Establishing verification procedures to ensure that the HACCP system is working effectively.

- Establishing documentation and record-keeping procedures to document the HACCP system and its implementation.

2. How would you develop and implement a HACCP plan for a new product or process?

Planning

- Assemble a HACCP team.

- Describe the product and its intended use.

- Identify the potential hazards associated with the product and its production process.

- Determine the CCPs.

- Establish critical limits for each CCP.

- Establish monitoring procedures for each CCP.

- Establish corrective actions for each CCP.

- Establish verification procedures.

- Establish documentation and record-keeping procedures.

Implementation

- Train employees on the HACCP plan.

- Implement the HACCP plan.

- Monitor the CCPs.

- Take corrective actions as needed.

- Verify the HACCP plan.

- Document and record the HACCP plan and its implementation.

3. How would you train and educate employees on HACCP?

I would train and educate employees on HACCP by:

- Developing a training plan that covers the seven principles of HACCP, the HACCP plan, and the employee’s role in implementing the HACCP plan.

- Conducting training sessions for employees at all levels of the organization.

- Providing employees with handouts and other resources to help them learn about HACCP.

- Answering employees’ questions about HACCP.

- Observing employees to ensure that they are following the HACCP plan.

- Providing feedback to employees on their performance.

4. How would you audit a HACCP system?

I would audit a HACCP system by:

- Reviewing the HACCP plan.

- Observing the HACCP system in operation.

- Interviewing employees about their understanding of the HACCP system.

- Reviewing records of HACCP monitoring and corrective actions.

- Evaluating the HACCP system’s effectiveness in preventing food safety hazards.

- Reporting my findings and recommendations to management.

5. What are the most common challenges in implementing a HACCP system?

The most common challenges in implementing a HACCP system are:

- Obtaining top management commitment.

- Assembling a HACCP team with the necessary expertise.

- Identifying all potential hazards and determining the CCPs.

- Establishing critical limits that are scientifically обоснованный.

- Developing monitoring procedures that are effective and efficient.

- Establishing corrective actions that are effective and feasible.

- Training employees on the HACCP system.

- Maintaining the HACCP system over time.

6. What are the benefits of implementing a HACCP system?

The benefits of implementing a HACCP system include:

- Improved food safety.

- Reduced risk of foodborne illness outbreaks.

- Increased consumer confidence.

- Improved brand reputation.

- Increased sales.

- Reduced costs associated with foodborne illness outbreaks.

- Improved compliance with regulatory requirements.

7. What are the key elements of a successful HACCP system?

The key elements of a successful HACCP system include:

- Top management commitment.

- A HACCP team with the necessary expertise.

- A comprehensive HACCP plan.

- Effective monitoring procedures.

- Effective corrective actions.

- Employee training.

- Regular audits.

- Continuous improvement.

8. What are the differences between HACCP and ISO 22000?

HACCP and ISO 22000 are both food safety management systems, but there are some key differences between the two.

- HACCP is a hazard-based system that focuses on identifying and controlling food safety hazards.

- ISO 22000 is a more comprehensive system that includes HACCP, as well as other elements such as good manufacturing practices (GMPs) and good hygiene practices (GHPs).

- HACCP is a mandatory requirement for food businesses in some countries, while ISO 22000 is a voluntary standard.

- HACCP is typically implemented by food businesses themselves, while ISO 22000 can be implemented by food businesses or by third-party certification bodies.

9. What are the future trends in HACCP?

The future trends in HACCP include:

- The use of technology to improve HACCP implementation.

- The development of HACCP systems for new and emerging food technologies.

- The increasing importance of HACCP in the global food supply chain.

- The harmonization of HACCP standards around the world.

10. What are your strengths and weaknesses as a HACCP Coordinator?

Strengths

- I have a strong understanding of the seven principles of HACCP.

- I have experience developing and implementing HACCP plans for a variety of food products and processes.

- I am a certified HACCP auditor.

- I am a good communicator and trainer.

- I am passionate about food safety.

Weaknesses

- I am relatively new to the role of HACCP Coordinator.

- I do not have experience with all types of food products and processes.

- I am not a registered dietitian.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hazard Analysis and Critical Control Point Coordinator (HACCP Coordinator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hazard Analysis and Critical Control Point Coordinator (HACCP Coordinator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A HACCP Coordinator is a critical role in the food industry, responsible for ensuring the safety and quality of food products. Here are their key job responsibilities:

1. Develop and implement HACCP plans

Understanding the HACCP principles and developing HACCP plans that outline the potential hazards and critical control points in food production processes.

- Conduct hazard analysis to identify potential biological, chemical, and physical hazards.

- Establish critical control points (CCPs) for the prevention, elimination, or reduction of identified hazards.

2. Monitor and verify HACCP systems

Monitoring and verifying the effectiveness of HACCP systems to ensure compliance with food safety regulations and standards.

- Monitor and record CCPs and other critical parameters to ensure they are within established limits.

- Conduct internal audits and inspections to assess the effectiveness of HACCP systems.

3. Train and educate staff

Providing training and education to staff on HACCP principles, procedures, and best practices to ensure food safety.

- Develop and deliver training programs on HACCP and food safety.

- Monitor staff knowledge and understanding of HACCP principles.

4. Maintain documentation and records

Maintaining accurate and up-to-date documentation and records of HACCP activities and findings.

- Maintain HACCP plans, monitoring records, and audit reports.

- Document and communicate any deviations from established HACCP procedures.

Interview Tips

To ace your interview for a HACCP Coordinator position, consider the following tips:

1. Research the company and the industry

Before the interview, thoroughly research the company and the food industry, demonstrating your knowledge and interest in the field.

- Visit their website, social media pages, and industry publications.

- Identify the company’s mission, values, and food safety initiatives.

2. Highlight your HACCP knowledge and experience

During the interview, emphasize your strong understanding of HACCP principles and experience in developing and implementing HACCP plans.

- Describe your involvement in the development and implementation of HACCP systems in previous roles.

- Discuss your knowledge of food safety regulations, standards, and best practices.

3. Demonstrate your communication and interpersonal skills

As a HACCP Coordinator, you will need to effectively communicate with staff at all levels, so highlight your strong communication and interpersonal skills.

- Explain how you have successfully trained and educated staff on HACCP principles.

- Share examples of how you have effectively communicated food safety issues to management and staff.

4. Prepare for common interview questions

Familiarize yourself with common interview questions for HACCP Coordinator positions and prepare thoughtful responses that showcase your knowledge and abilities.

- Describe your understanding of the HACCP principles and how you have applied them in your work.

- Explain your experience in monitoring and verifying HACCP systems.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hazard Analysis and Critical Control Point Coordinator (HACCP Coordinator), it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hazard Analysis and Critical Control Point Coordinator (HACCP Coordinator) positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.