Feeling lost in a sea of interview questions? Landed that dream interview for Head Filter Press Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Head Filter Press Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

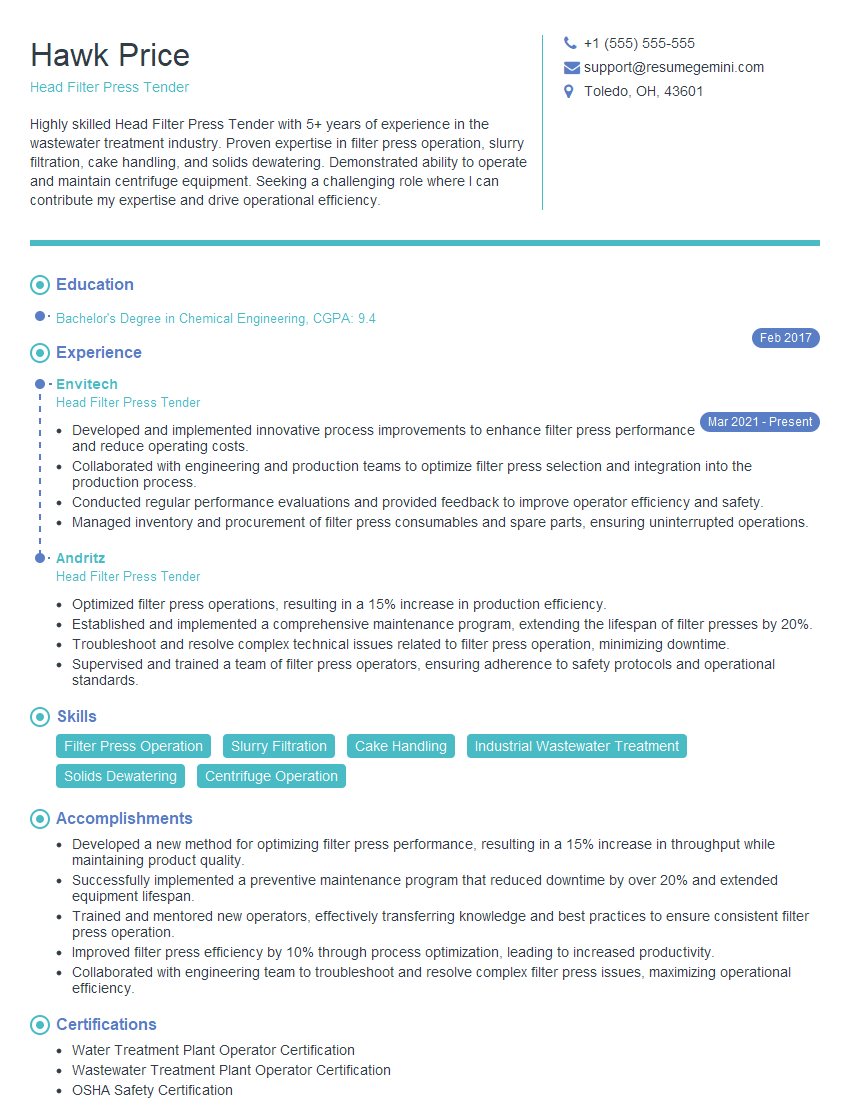

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Filter Press Tender

1. What are the key responsibilities of a Head Filter Press Tender?

As a Head Filter Press Tender, I would be responsible for:

- Operating, monitoring, and maintaining filter press equipment to ensure efficient and continuous operation.

- Controlling slurry flow and feed rates to optimize filter performance.

- Monitoring filter cake thickness, moisture content, and quality to meet specifications.

- Cleaning and maintaining filter press plates, frames, and ancillary equipment.

- Troubleshooting and resolving equipment malfunctions and process issues.

2. Describe the process of filter press operation.

Slurry Preparation

- Slurry is prepared by mixing solids and liquids to create a suspension.

- The slurry is pumped into the filter press.

Filtration

- The slurry enters the filter chambers and solids are trapped on the filter media.

- Liquids pass through the filter media and are discharged.

Cake Formation

- Solids accumulate on the filter media to form filter cakes.

- The cakes are compressed to expel residual liquids.

Cake Discharge

- The filter press is opened.

- The filter cakes are discharged from the chambers.

3. What are the different types of filter press designs?

Filter press designs include:

- Recessed-plate filter presses

- Chamber filter presses

- Membrane filter presses

- Automatic filter presses

- Semi-automatic filter presses

- Manual filter presses

4. What factors influence filter press performance?

Filter press performance is influenced by:

- Slurry composition

- Filter media

- Operating pressure

- Filtration time

- Filter press design

- Maintenance and operation practices

5. How do you troubleshoot common filter press problems?

Common filter press problems and troubleshooting steps include:

- Low filtrate flow rate: Clean or replace filter media, adjust slurry feed rate, check for blockages.

- Thick filter cakes: Optimize slurry chemistry, increase filtration pressure, reduce filtration time.

- Leaks: Inspect and tighten gaskets and seals, check for damaged plates or frames.

- Uneven cake thickness: Adjust feed distribution, inspect filter media for tears or holes.

- Mechanical failures: Check hydraulic systems, pumps, and other equipment for malfunctions.

6. What safety precautions are important when operating a filter press?

Safety precautions for filter press operation include:

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures when performing maintenance.

- Be aware of potential hazards such as moving parts, pressure systems, and hot surfaces.

- Keep work area clean and organized.

- Receive proper training and authorization before operating the filter press.

7. How do you ensure the quality of filter cakes produced by the filter press?

To ensure filter cake quality, I would:

- Monitor filter cake thickness, moisture content, and appearance.

- Conduct regular testing to verify cake quality against specifications.

- Adjust operating parameters such as filtration pressure and time as needed.

- Maintain filter press equipment and ensure proper operation.

- Document filter press performance and cake quality data for analysis and improvement.

8. Describe your experience in optimizing filter press operations.

In my previous role, I implemented several strategies to optimize filter press operations, including:

- Adjusted slurry feed rates and filtration pressures to improve filtrate flow rates and cake quality.

- Optimized cleaning and maintenance schedules to minimize downtime and extend equipment life.

- Trained operators on best practices for filter press operation and troubleshooting.

- Collaborated with process engineers to improve slurry preparation and filtration efficiency.

- As a result, I was able to significantly increase filter press productivity and reduce operating costs.

9. How do you stay up-to-date with the latest developments in filter press technology?

To stay up-to-date with the latest developments in filter press technology, I:

- Attend industry conferences and webinars.

- Read technical articles and research papers.

- Network with other filter press professionals.

- Explore new equipment and technologies from filter press manufacturers.

- Participate in ongoing training and development programs.

10. Why are you interested in working as a Head Filter Press Tender for our company?

I am eager to join your company as a Head Filter Press Tender because:

- I am highly skilled and experienced in filter press operation, maintenance, and optimization.

- I am passionate about delivering high-quality results and continuous improvement.

- I am impressed by your company’s commitment to safety and innovation.

- I believe that my skills and experience would be a valuable asset to your team.

- I am eager to contribute to the success of your company and the industry as a whole.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Filter Press Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Filter Press Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Head Filter Press Tender is responsible for overseeing the operation and maintenance of filter press equipment. They will assist in the production of specified products through mixing, filtering, and pressing operations. Their shift schedule is based on production requirements and can include weekends and holidays.

1. Operation of Equipment

The Head Filter Press Tender will be responsible for the operation of all the filter press equipment. They will maintain the systems in good working condition and make sure they are running safely and efficiently.

- Operate the filter press to separate solids from liquids.

- Monitor the operation of the filter press and make adjustments as needed.

- Maintain the filter press and its components.

- Clean the filter press and its components.

2. Maintenance

The Head Filter Press Tender will keep records of all maintenance performed on the filter press equipment. They will also be responsible for troubleshooting any problems that may occur.

- Perform routine maintenance on the filter press.

- Troubleshoot and repair problems with the filter press.

- Maintain a maintenance log for the filter press.

- Order and maintain a stock of spare parts for the filter press.

3. Safety

The Head Filter Press Tender will have a responsibility for ensuring a safe work environment. They will maintain a clean and orderly work area and will follow all safety procedures.

- Follow all safety rules and procedures.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and orderly work area.

- Report any unsafe conditions or practices to the supervisor.

4. Quality Control

The Head Filter Press Tender will be responsible for ensuring that the product produced by the filter press meets quality standards. They will monitor the product and make adjustments to the filter press as needed.

- Monitor the quality of the product produced by the filter press.

- Make adjustments to the filter press as needed to meet quality standards.

- Maintain records of all quality control checks performed.

- Report any quality control problems to the supervisor.

Interview Tips

Preparing for an interview for a Head Filter Press Tender position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you go on your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the position and what the company is looking for in a candidate.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company, if possible.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions ahead of time so that you can deliver your responses confidently and concisely.

- Write out your answers to common interview questions.

- Practice answering these questions out loud.

- Get feedback from friends or family members on your answers.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience and how it qualifies you for the position. Be prepared to talk about your experience in detail, including your responsibilities, accomplishments, and any relevant skills or knowledge you have.

- Create a resume that highlights your relevant experience and skills.

- Prepare stories that illustrate your experience and how it relates to the position.

- Be able to articulate your skills and how they can benefit the company.

4. Ask Questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position. It is also a chance to show the interviewer that you are interested in the position and that you have done your research.

- Prepare a few questions to ask the interviewer.

- These questions should be about the company, the position, or the industry.

- Asking questions shows that you are interested in the position and that you have done your research.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Head Filter Press Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!