Are you gearing up for a career in Head Knitting Machine Fixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Head Knitting Machine Fixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

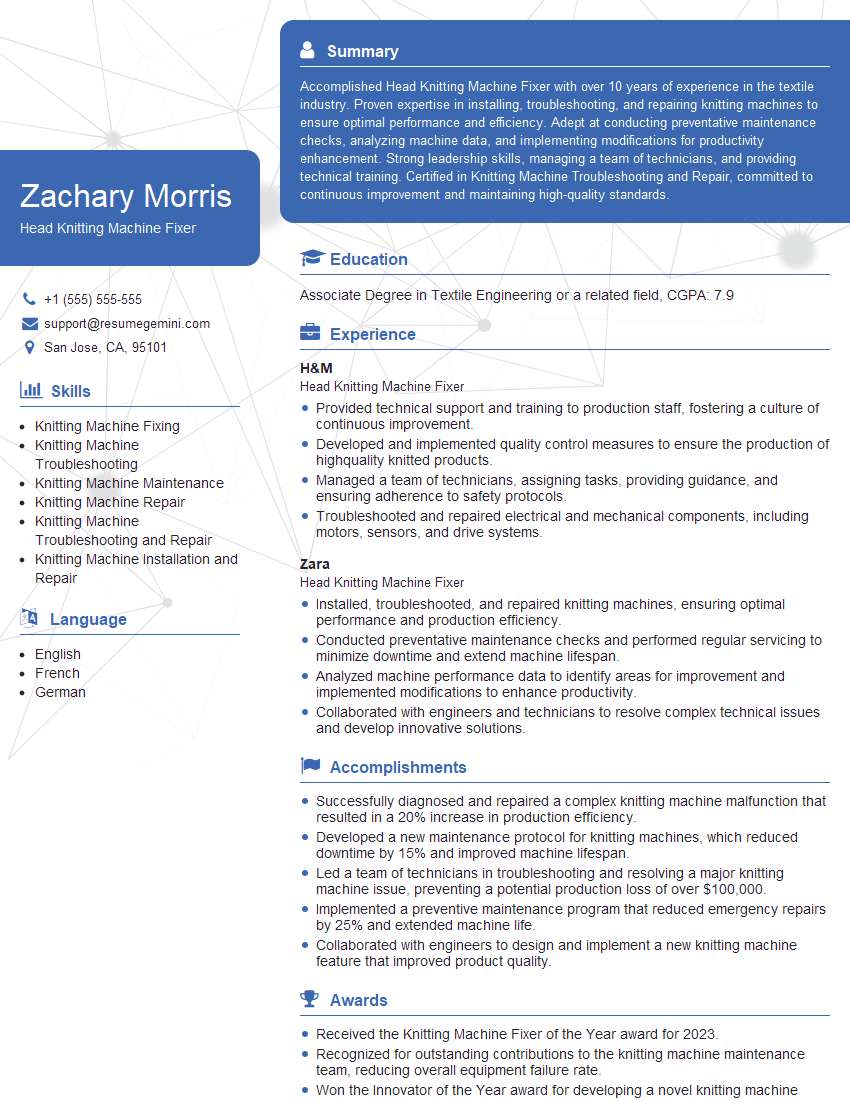

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Knitting Machine Fixer

1. Explain the role and responsibilities of a Head Knitting Machine Fixer?

- Supervise and coordinate the activities of knitting machine mechanics and technicians.

- Diagnose and troubleshoot knitting machine malfunctions and repairs.

- Develop and implement preventative maintenance programs.

- Train and supervise new knitting machine mechanics.

- Ensure that knitting machines are operating at peak efficiency.

2. Describe the different types of knitting machines and their applications?

- Flat knitting machines: Used to produce flat fabrics, such as T-shirts and sweatshirts.

- Circular knitting machines: Used to produce tubular fabrics, such as socks and stockings.

- Warp knitting machines: Used to produce fabrics with a high degree of stretch, such as swimwear and lingerie.

3. Explain the principles of operation of a knitting machine?

Knitting machines use needles to form loops of yarn into fabric. The needles are arranged in a specific pattern to create the desired stitch. The yarn is fed through the needles and the needles are then moved in a specific sequence to form the loops.

4. Describe the different types of knitting needles and their uses?

- Latch needles: Used to create plain stitches.

- Spring needles: Used to create ribbed stitches.

- Compound needles: Used to create a variety of stitches.

5. Explain the process of setting up a knitting machine for a new job?

- Select the appropriate yarn and needles for the job.

- Set the machine to the correct stitch pattern.

- Adjust the machine settings to the desired fabric width and length.

- Thread the yarn through the machine.

- Start the machine and monitor the fabric production.

6. Describe the different types of knitting defects and their causes?

- Dropped stitches: Caused by a needle not picking up the yarn correctly.

- Runaway stitches: Caused by a needle not holding the yarn correctly.

- Holes in the fabric: Caused by a broken needle or a yarn break.

- Puckering: Caused by uneven tension on the yarn.

- Wrinkles: Caused by improper handling of the fabric after it has been knitted.

7. Explain the importance of preventive maintenance for knitting machines?

Preventive maintenance helps to keep knitting machines running smoothly and efficiently. It can help to prevent breakdowns, reduce downtime, and extend the life of the machines.

8. Describe the different types of preventive maintenance tasks that should be performed on knitting machines?

- Cleaning and lubricating the machine.

- Inspecting and replacing worn parts.

- Calibrating the machine.

- Performing test runs.

9. Explain the importance of safety when working with knitting machines?

Knitting machines can be dangerous if they are not operated properly. It is important to follow all safety precautions, such as wearing appropriate clothing, keeping hands away from moving parts, and never operating a machine that is not in good condition.

10. What are the latest trends in knitting technology?

- The use of computerized knitting machines.

- The development of new knitting yarns.

- The use of 3D knitting technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Knitting Machine Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Knitting Machine Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Head Knitting Machine Fixer is responsible for overseeing the maintenance and repair of knitting machines within a manufacturing facility. They work closely with production staff to ensure that machines are operating efficiently and effectively, and they play a crucial role in minimizing downtime and maximizing productivity.

1. Maintenance and Repair

The Head Knitting Machine Fixer is responsible for performing regular maintenance tasks on all knitting machines, including:

- Inspecting and cleaning machines

- Adjusting and calibrating machines

- Replacing worn parts

- Repairing minor breakdowns

2. Troubleshooting

When a knitting machine breaks down, the Head Knitting Machine Fixer is responsible for troubleshooting the problem and implementing a solution. This may involve:

- Identifying the source of the problem

- Replacing or repairing damaged parts

- Adjusting machine settings

3. Training and Supervision

The Head Knitting Machine Fixer is also responsible for training and supervising other knitting machine fixers. This includes:

- Providing on-the-job training

- Answering questions and providing support

- Evaluating performance and providing feedback

4. Safety

The Head Knitting Machine Fixer is responsible for ensuring that all knitting machines are operated safely. This includes:

- Identifying potential hazards

- Implementing safety procedures

- Training machine operators on safety protocols

Interview Tips

Preparing for an interview for a Head Knitting Machine Fixer position can be challenging, but there are a few things you can do to increase your chances of success.

1. Research the Company and the Position

Before you go on an interview, it’s important to do your research and learn as much as you can about the company and the position you’re applying for. This will help you understand the company’s culture, goals, and needs, and it will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about its history, products, and services.

- Read news articles and industry publications to learn about the company’s recent developments.

- Network with people who work at the company or in the industry.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “What is your experience with knitting machines?”

- “What are your salary expectations?”

It’s important to practice your answers to these questions so that you can deliver them confidently and clearly.

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a clean, pressed suit or business casual attire. You should also make sure that your shoes are clean and polished, and that your hair and nails are neatly groomed.

4. Be Punctual

Punctuality is important for any job interview, but it’s especially important for a Head Knitting Machine Fixer position. This is because you need to demonstrate that you’re reliable and that you can manage your time effectively.

5. Be Prepared to Answer Technical Questions

In addition to the common interview questions, you’re also likely to be asked technical questions about knitting machines. These questions may be designed to test your knowledge of the different types of knitting machines, their components, and their operation. It’s important to review your notes on knitting machines before your interview so that you can answer these questions confidently.

6. Ask Questions

At the end of the interview, you should always ask the interviewer questions. This shows that you’re interested in the position and that you’re taking the interview seriously. Some good questions to ask include:

- “What are the biggest challenges facing the company right now?”

- “What are the company’s goals for the next year?”

- “What is the company culture like?”

- “What are the opportunities for advancement?”

- “When can I expect to hear back from you?”

7. Follow Up

After the interview, it’s important to follow up with the interviewer. This shows that you’re still interested in the position and that you’re eager to learn more. You can follow up with a thank-you note or an email, and you can also check in with the interviewer a few days later to see if they have any updates.

Next Step:

Now that you’re armed with the knowledge of Head Knitting Machine Fixer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Head Knitting Machine Fixer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini