Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Head Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

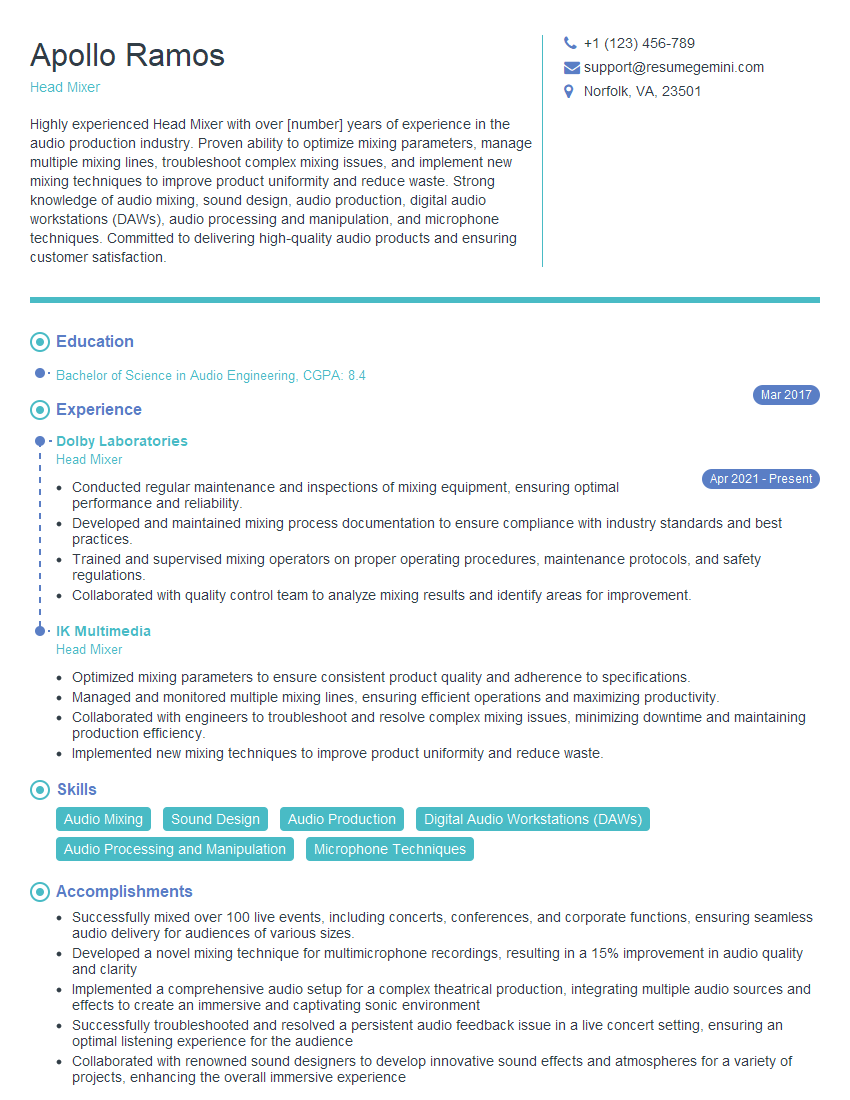

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Mixer

1. What are the key responsibilities of a Head Mixer?

As a Head Mixer, I would be responsible for leading, supervising, and ensuring the efficient operation of the mixing department within a manufacturing facility. My key responsibilities would include:

- Supervising and guiding a team of mixing operators to ensure adherence to established mixing processes and quality standards.

- Monitoring and controlling mixing equipment, including blenders, mixers, and agitators, to achieve optimal mixing results.

- Developing and implementing standardized operating procedures (SOPs) to ensure quality and consistency in mixing operations.

- Maintaining detailed records and documentation related to mixing processes, including batch logs, quality control data, and equipment maintenance.

- Working closely with other departments, such as production, quality control, and engineering, to facilitate smooth production processes.

2. Describe the different types of mixing processes and the factors that influence their selection.

Batch Mixing

- Suitable for small-scale production or when high precision is required.

- Involves mixing ingredients in a single batch, which is then discharged before the next batch is processed.

Continuous Mixing

- Used for large-scale production and when a consistent mixture is required.

- Involves continuously feeding ingredients into a mixer and discharging the mixed product.

Factors Influencing Selection:

- Product characteristics (e.g., viscosity, particle size, reactivity)

- Desired degree of mixing and uniformity

- Production capacity and batch size requirements

- Equipment availability and cost

3. What are the common challenges faced in mixing operations and how would you overcome them?

Some common challenges in mixing operations include:

- Achieving uniform mixing and avoiding segregation of ingredients.

- Controlling mixing time and energy input to avoid overmixing or undermixing.

- Preventing cross-contamination between different products or batches.

To overcome these challenges, I would implement the following strategies:

- Selecting the appropriate mixing equipment and process based on product characteristics and mixing requirements.

- Optimizing mixing parameters (e.g., speed, time, temperature) through experimentation and data analysis.

- Implementing rigorous cleaning and sanitation procedures to prevent cross-contamination.

4. How do you ensure the quality of mixed products?

To ensure the quality of mixed products, I would implement a comprehensive quality assurance program that includes:

- Establishing and maintaining clear quality standards and specifications for mixed products.

- Conducting regular quality control checks, including in-process testing and finished product analysis.

- Maintaining detailed records and documentation of all quality control activities.

- Investigating and implementing corrective actions in case of any quality deviations.

5. What are the safety protocols that you would implement in a mixing department?

To ensure a safe work environment in the mixing department, I would implement the following safety protocols:

- Providing proper training and safety gear to all employees.

- Establishing clear operating procedures and safety guidelines.

- Conducting regular safety inspections and audits.

- Maintaining a clean and organized work area.

- Having emergency response plans in place and conducting drills.

6. How do you stay updated with the latest advancements in mixing technology?

To stay updated with the latest advancements in mixing technology, I would:

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Consult with equipment manufacturers and industry experts.

- Participate in continuing education programs.

7. Describe a situation where you had to troubleshoot a mixing issue and what steps you took to resolve it.

In a previous role, we encountered a problem with uneven mixing in a batch mixing process. To troubleshoot the issue, I followed these steps:

- Examined the ingredients and mixing procedure to identify any potential sources of error.

- Checked the mixing equipment (blender) for proper operation and calibration.

- Adjusted the mixing parameters (speed, time, temperature) to optimize mixing.

- Tested different mixing sequences and techniques to improve uniformity.

After implementing these measures, we successfully resolved the mixing issue and achieved the desired uniformity in the mixed product.

8. How do you motivate and lead a team of mixing operators?

To motivate and lead a team of mixing operators, I would:

- Communicate clear expectations and provide regular feedback.

- Recognize and reward individual and team achievements.

- Foster a positive and supportive work environment.

- Empower team members to take ownership of their responsibilities.

- Provide opportunities for professional development and growth.

9. Tell me about a time when you faced a difficult customer complaint related to mixing. How did you handle the situation?

In a previous role, I received a complaint from a customer about inconsistent mixing in a product. I took the following steps to resolve the issue:

- Contacted the customer to gather specific details about the issue.

- Investigated the mixing process and identified the root cause of the inconsistency.

- Implemented corrective actions to address the issue.

- Communicated the resolution to the customer and followed up to ensure satisfaction.

By handling the complaint promptly and effectively, I was able to maintain a positive relationship with the customer and preserve their trust in our products.

10. How do you prioritize tasks and manage multiple projects simultaneously in a fast-paced manufacturing environment?

In a fast-paced manufacturing environment, I prioritize tasks based on the following criteria:

- Impact on production and customer satisfaction

- Urgency and deadlines

- Resource availability

- Potential risks and consequences

To manage multiple projects simultaneously, I use a combination of tools and techniques, including:

- Project planning and scheduling

- Delegation and teamwork

- Effective communication and coordination

- Continuous monitoring and evaluation

By following these principles, I am able to ensure that critical tasks are completed on time and to the required standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The head mixer plays a pivotal role in ensuring the smooth and efficient operation of the mixing process. Their primary responsibilities encompass managing the day-to-day operations of the mixing department, supervising staff, and maintaining quality standards.

1. Production and Quality Management

Overseeing the entire mixing process, the head mixer is responsible for:

- Scheduling and coordinating mixing operations

- Establishing and maintaining production targets

- Monitoring and ensuring product quality meets specifications

- Identifying and resolving production issues promptly

2. Staff Management

Leading and supervising a team of mixing operators, the head mixer is responsible for:

- Training, mentoring, and motivating staff

- Assigning tasks and monitoring performance

- Maintaining a positive and productive work environment

- Ensuring adherence to safety regulations and procedures

3. Equipment Maintenance

Maintaining and troubleshooting mixing equipment is a crucial aspect of the head mixer’s role, including:

- Inspecting and maintaining equipment regularly

- Identifying and repairing equipment malfunctions

- Coordinating with maintenance technicians for major repairs

- Ensuring equipment is operating safely and efficiently

4. Process Optimization

Continuously striving to improve the mixing process, the head mixer is responsible for:

- Identifying and implementing process improvements

- Reducing waste and optimizing resource utilization

- Collaborating with other departments to enhance overall efficiency

- Staying abreast of industry best practices and technological advancements

Interview Tips

To ace the interview for a head mixer position, thorough preparation and showcasing your relevant skills and experience are essential. Here are some tips to help you succeed:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Learn about the specific responsibilities and requirements of the head mixer role within that company.

2. Highlight Your Technical Expertise

Demonstrate your in-depth understanding of mixing processes, equipment, and quality control techniques. Provide specific examples of how you have optimized processes and resolved production issues.

3. Emphasize Leadership and Management Skills

Showcase your ability to lead and motivate a team, delegate tasks effectively, and create a positive work environment. Share instances where you have successfully managed and developed staff.

4. Quantify Your Accomplishments

Use data and metrics to quantify your accomplishments in previous roles. For example, highlight how you improved production efficiency by a certain percentage or reduced waste through process optimization.

5. Be Prepared for Industry-Specific Questions

Expect questions about your knowledge of industry regulations, safety protocols, and technological advancements in mixing. Prepare answers that demonstrate your understanding and commitment to industry standards.

6. Practice Your Interview Skills

Practice answering common interview questions aloud. This will help you articulate your answers clearly and confidently during the interview. Consider seeking feedback from a mentor or career counselor.

7. Prepare Questions for the Interviewers

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions that demonstrate your curiosity about the company, the team, and the challenges and opportunities of the head mixer role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Head Mixer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Head Mixer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.