Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Head Still Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Head Still Operator so you can tailor your answers to impress potential employers.

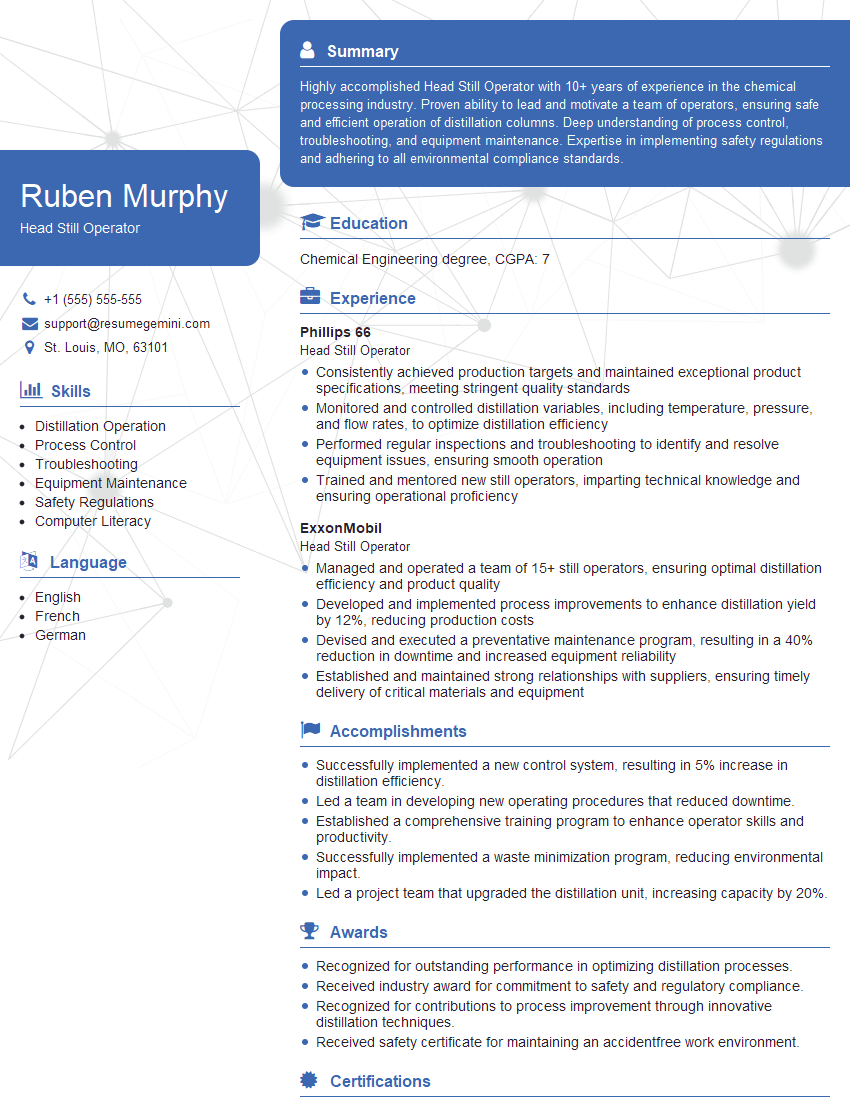

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Still Operator

1. How would you handle a situation where the distillation column is experiencing flooding?

- Identify the cause of the flooding (e.g., high feed rate, low reflux ratio, foaming, etc.)

- Implement corrective actions to address the cause (e.g., reduce feed rate, increase reflux ratio, add antifoam, etc.)

- Monitor the column performance and make necessary adjustments to maintain stable operation

2. How do you ensure the purity of the distillate produced by the distillation column?

Reflux Ratio Optimization:

- Adjusting reflux ratio to achieve the desired product purity

- Monitoring reflux temperature and composition to ensure proper operation

Condenser Efficiency Maintenance:

- Inspecting and cleaning the condenser to prevent fouling

- Ensuring proper cooling medium flow and temperature

Separation Efficiency Monitoring:

- Analyzing distillate and bottoms samples to verify purity

- Identifying and addressing any deviations from target specifications

3. How do you troubleshoot and resolve a problem with the level control system in the distillation column?

- Verify the level transmitter input and output signals

- Inspect the level control valve and actuator for proper operation

- Check the control loop tuning parameters and adjust as necessary

- Consider external factors that may affect level control, such as feed variations or changes in product demand

4. How do you maintain the efficiency of the heat exchangers used in the distillation process?

- Regularly clean and inspect heat exchangers to remove fouling

- Monitor heat exchanger temperatures and pressures to ensure proper operation

- Optimize heat transfer rates by adjusting flow rates and temperatures

- Consider chemical cleaning or mechanical cleaning methods to address specific fouling issues

5. How do you handle a situation where the feed composition to the distillation column changes?

- Analyze the new feed composition and determine its impact on the distillation process

- Adjust operating parameters, such as reflux ratio and heat input, to accommodate the changes

- Monitor the column performance and make further adjustments as necessary to maintain product purity and yield

6. How do you ensure the safety of the distillation unit and its operators?

- Adhere to all safety protocols and procedures

- Conduct regular safety inspections and risk assessments

- Provide training to operators on safe operating practices

- Implement emergency response plans and procedures

- Monitor process parameters and take immediate action to address any deviations or potential hazards

7. How do you stay updated on the latest developments and best practices in distillation technology?

- Attend conferences and workshops

- Read industry publications and technical journals

- Participate in online forums and discussions

- Network with other professionals in the field

- Pursue professional development opportunities, such as certifications or advanced degrees

8. How do you manage a team of operators and ensure their performance meets the required standards?

Clear Communication:

- Establishing clear expectations and goals

- Providing regular feedback and guidance

Performance Monitoring:

- Tracking key performance indicators (KPIs)

- Identifying areas for improvement and providing support

Training and Development:

- Providing opportunities for operators to enhance their skills and knowledge

- Encouraging professional development and certification

9. How do you handle a situation where there is a conflict between production targets and safety considerations?

- Prioritize safety above all else

- Communicate the potential risks and consequences to management

- Explore alternative solutions that balance production goals with safety requirements

- Involve operators and other stakeholders in the decision-making process

10. How do you optimize the distillation process to minimize energy consumption and environmental impact?

Energy Efficiency Measures:

- Optimizing heat exchanger configurations and flow rates

- Utilizing energy recovery systems (e.g., heat pumps, condensers)

Waste Reduction:

- Minimizing product losses through efficient operation

- Exploring waste recycling or reuse opportunities

Environmental Compliance:

- Adhering to environmental regulations and standards

- Implementing pollution control measures (e.g., scrubbers, filters)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Head Still Operator is responsible for overseeing the operations of a distillation plant, ensuring the production of high-quality spirits.

1. Production Management

Supervises and coordinates the activities of still operators to optimize production efficiency and meet production targets.

- Plans production schedules and allocates resources to ensure smooth operations.

- Monitors production processes, identifying and resolving any bottlenecks or issues.

2. Quality Control

Ensures the production of high-quality spirits by adhering to established standards and regulations.

- Conducts regular quality checks on raw materials, intermediate products, and finished spirits.

- Maintains records of quality control data and implements corrective actions as needed.

3. Equipment Maintenance

Ensures the proper functioning and maintenance of distillation equipment to prevent breakdowns and ensure safety.

- Conducts regular inspections and maintenance of stills, condensers, and other equipment.

- Coordinates with maintenance personnel for repairs and replacements as required.

4. Safety Compliance

Enforces safety regulations and procedures to ensure a safe working environment.

- Conducts safety inspections and training for operators.

- Monitors and reports on safety incidents and implements corrective measures to prevent their recurrence.

Interview Tips

Preparing for an interview for the position of Head Still Operator requires thorough research, practice, and a positive attitude.

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and values.

- Research the industry and market trends to demonstrate your understanding of the field.

- Review the job description thoroughly to identify the key responsibilities and qualifications for the role.

2. Practice Answering Common Interview Questions

Anticipate typical interview questions and prepare insightful answers.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples from your experience.

- Highlight your skills, knowledge, and accomplishments that are directly relevant to the job requirements.

3. Showcase Your Technical Expertise

Demonstrate your understanding of distillation processes, equipment, and safety protocols.

- Discuss your experience in optimizing production, conducting quality control, and ensuring compliance with industry standards.

- Highlight your ability to solve problems, analyze data, and make informed decisions.

4. Emphasize Your Leadership and Communication Skills

The Head Still Operator is a leadership role, requiring strong communication and interpersonal skills.

- Provide examples of how you have successfully managed teams, motivated employees, and resolved conflicts.

- Highlight your ability to communicate clearly and effectively with both technical and non-technical audiences.

5. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your interest and engagement.

- Inquire about the company’s growth plans and industry outlook.

- Seek information on the company’s commitment to safety and quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Head Still Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!