Are you gearing up for an interview for a Head Wood Grinder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Head Wood Grinder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

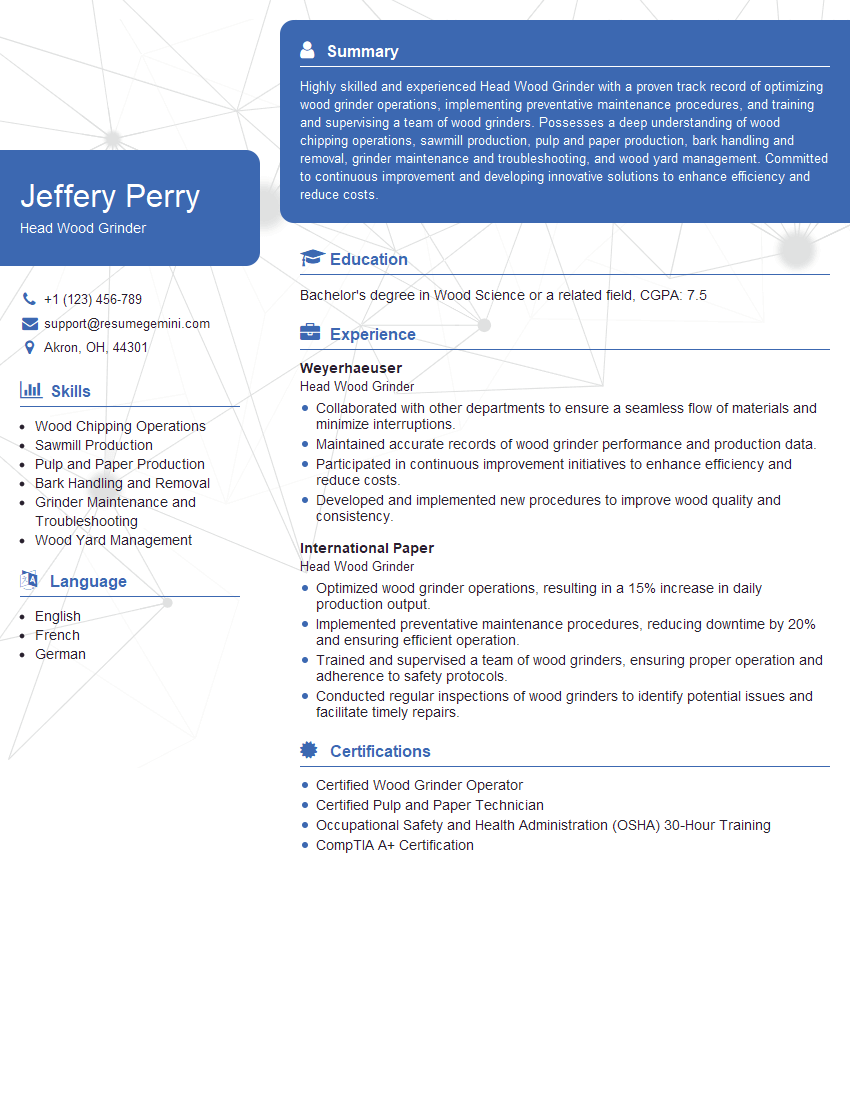

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Head Wood Grinder

1. How do you determine the optimal operating parameters for a wood grinder, such as feed rate, knife clearance, and screen size, to achieve the desired product quality and throughput?

To determine the optimal operating parameters, I consider several factors:

- Wood species and moisture content: Different wood species and their moisture levels impact the grinding process and desired product quality.

- Desired product specifications: The target particle size, shape, and consistency influence the choice of parameters.

- Grinder type and design: The specific grinder model and its features affect the operating range and efficiency.

- Power consumption and wear rate: I analyze the trade-off between throughput, energy consumption, and the longevity of grinding components.

Based on these factors, I conduct trial runs, monitor process parameters, and make adjustments to find the optimal combination that meets production goals while maintaining product quality.

2. Describe the different types of wood grinders and their suitability for various applications.

Chipper grinders

- High throughput and coarse particle size

- Suitable for large-scale operations, such as producing wood chips for fuel or industrial purposes

Disc grinders

- Medium throughput and variable particle size

- Can be used for both primary and secondary grinding

Hammer mills

- High throughput and fine particle size

- Used for producing wood flour or other applications requiring very fine particles

Attrition mills

- Low throughput and ultra-fine particle size

- Suitable for specialized applications, such as producing pigments or pharmaceuticals

3. How do you ensure the efficient operation and maintenance of a wood grinder system?

- Regular inspections and maintenance: Scheduled inspections allow for early detection of any potential issues, such as wear or damage to components.

- Condition monitoring: Sensors and monitoring systems can provide real-time data on grinder performance, enabling proactive maintenance.

- Spare parts inventory: Maintaining an adequate inventory of critical spare parts reduces downtime in case of unscheduled maintenance.

- Training and operator skills: Well-trained operators can identify and address potential problems early on, preventing major breakdowns.

- Collaboration with suppliers: Establishing relationships with reliable suppliers ensures access to technical support and genuine parts when needed.

4. What safety protocols and procedures are essential for operating a wood grinder?

- Machine guarding and lockout/tagout procedures: Ensuring proper machine guarding and implementing lock-out/tag-out procedures prevent accidents.

- Personal protective equipment (PPE): Enforcing the use of appropriate PPE, such as safety glasses, earplugs, and dust masks.

- Regular safety training: Conducting regular safety training for operators to reinforce safe practices and emergency response procedures.

- Hazard identification and risk assessment: Identifying potential hazards in the workplace and implementing mitigation measures.

- Emergency preparedness: Having emergency response plans and protocols in place, including evacuation procedures and contact information for emergency services.

5. How do you troubleshoot and resolve common issues encountered in wood grinding operations?

- Reduced throughput: I check for worn or dull knives, blockages in the feed system, or power supply issues.

- Inconsistent product quality: I adjust feed rate, knife clearance, or screen size to optimize the grinding process.

- Excessive wear or damage to components: I inspect for improper operating parameters, contamination in the wood, or mechanical faults.

- Safety issues: I immediately shut down the grinder and investigate any safety concerns, following proper lockout/tagout procedures.

- Electrical problems: I consult with an electrician to diagnose and resolve any electrical issues, prioritizing safety and compliance with electrical codes.

6. Describe your experience in optimizing wood grinder performance through process control techniques.

In my previous role, I successfully applied process control techniques to optimize wood grinder performance. I used:

- Statistical process control (SPC) to monitor and analyze key process parameters, such as feed rate, power consumption, and particle size distribution.

- Feedback control loops to adjust operating parameters automatically based on sensor readings, maintaining optimal conditions.

- Advanced predictive analytics to identify potential issues before they occur, enabling preventative maintenance and reducing downtime.

These techniques significantly improved grinder efficiency, reduced production variability, and minimized waste.

7. How do you stay up-to-date with the latest advancements in wood grinding technology and best practices?

- Industry conferences and trade shows: Attending industry events provides opportunities to learn about new technologies and network with experts.

- Technical publications and research papers: I regularly read industry journals and research publications to stay abreast of technological advancements.

- Collaboration with equipment manufacturers: Maintaining relationships with equipment manufacturers allows access to technical updates and potential beta-testing opportunities.

- Online resources and webinars: I utilize online platforms and webinars to stay informed about the latest trends and best practices.

8. Describe your leadership style as a Head Wood Grinder.

As a Head Wood Grinder, I adopt a collaborative and results-oriented leadership style. I emphasize:

- Teamwork and collaboration: I foster a team environment where everyone’s contributions are valued and respected.

- Clear communication: I ensure open and transparent communication to keep the team informed and aligned.

- Empowerment and accountability: I empower my team to make decisions and hold them accountable for their responsibilities.

- Continuous improvement: I encourage a culture of continuous improvement, seeking feedback and implementing innovative solutions.

- Development and mentorship: I prioritize the professional development of my team members and provide mentorship opportunities.

9. How do you manage production schedules and ensure on-time delivery of high-quality products?

- Effective planning and scheduling: I develop and implement detailed production schedules that optimize resource allocation and minimize bottlenecks.

- Real-time monitoring and tracking: I utilize production monitoring systems to track progress and identify any potential delays.

- Communication with customers: I maintain regular communication with customers to provide updates and proactively address any concerns.

- Contingency planning: I prepare contingency plans to mitigate potential disruptions and ensure timely delivery.

- Continuous improvement: I regularly review and refine production processes to identify opportunities for efficiency enhancements and reduced lead times.

10. Describe your experience in managing a team of wood grinders and ensuring a safe and productive work environment.

In my previous role, I effectively managed a team of wood grinders, prioritizing safety and productivity. I implemented the following strategies:

- Safety training and certification: I ensured that all team members were properly trained and certified in safety protocols and operating procedures.

- Regular safety inspections: I conducted regular safety inspections to identify and address potential hazards.

- Performance monitoring and feedback: I established clear performance metrics and provided regular feedback to team members, fostering a culture of continuous improvement.

- Open communication and collaboration: I promoted open communication and encouraged team members to share ideas and solutions.

- Recognition and rewards: I recognized and rewarded team members for their contributions and achievements, fostering motivation and a positive work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Head Wood Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Head Wood Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Head Wood Grinders are responsible for overseeing the operations of a wood grinding facility. They manage a team of workers and ensure that the facility meets its production targets.

1. Manage Production

Head Wood Grinders ensure that the facility produces high quality wood chips that meet the customer’s specifications.

- Set production goals and monitor progress

- Ensure that the grinders are operating at peak efficiency

2. Manage Personnel

Head Wood Grinders are responsible for the safety and well-being of their team. They must also motivate and train their team to achieve their goals.

- Hire, train, and supervise a team of workers

- Create a positive and safe work environment

3. Manage Equipment

Head Wood Grinders are responsible for maintaining the equipment in the facility. They must ensure that the equipment is operating safely and efficiently.

- Maintain and repair grinders and other equipment

- Order and track inventory

4. Manage Finances

Head Wood Grinders must manage the budget for the facility. They must also track costs and identify areas where savings can be made.

- Track expenses and revenue

- Identify areas for cost savings

Interview Tips

To help candidates ace their interview for a Head Wood Grinder position, here are some tips

1. Research the Company

Before the interview, candidates should research the company and the position they are applying for. They should learn about the company’s culture, values, and products.

- Visit the company’s website.

- Read articles about the company.

- Talk to people who work at the company.

2. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions, such as:

- Tell me about yourself.

- Why are you interested in working at this company?

- What are your strengths and weaknesses?

- What is your experience with wood grinding?

- How do you manage a team?

3. Know the Basic Principles of Wood Grinding

Candidates should know the basic principles of wood grinding. This includes:

- The different types of wood grinders.

- The factors that affect the quality of wood chips.

- The safety procedures that must be followed when operating a wood grinder.

4. Be Professional

Candidates should dress professionally and arrive on time for their interview. They should be polite and respectful to the interviewer.

- Dress in business attire.

- Be on time for your interview.

- Be polite and respectful to the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Head Wood Grinder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.