Are you gearing up for a career in Header Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Header Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

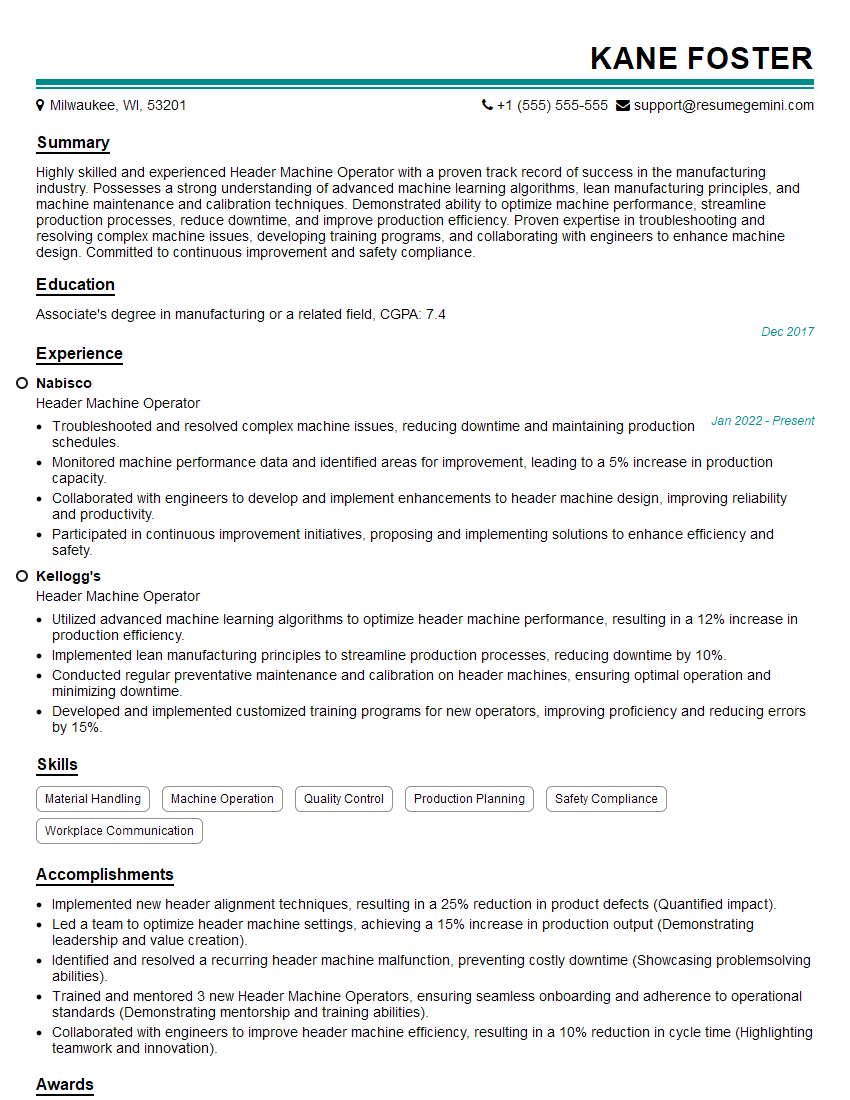

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Header Machine Operator

1. Describe the key responsibilities of a Header Machine Operator?

- Operate and maintain header machines to produce high-quality headers

- Monitor and adjust machine settings to ensure optimal performance and production efficiency

2. What are the different types of headers that can be produced on a header machine?

Round Headers

- Pan head

- Round head

Hexagon Head

- Hex washer head

- Hex flange head

3. Explain the process of setting up and operating a header machine?

- Load raw material into the machine

- Set machine parameters (e.g., feed rate, pressure, temperature)

- Monitor machine operation and make adjustments as needed

4. What are the common troubleshooting techniques used for header machines?

- Inspecting for blockages or wear in the machine

- Checking the raw material for defects

- Adjusting machine settings to optimize performance

5. What safety precautions should be taken when operating a header machine?

- Wear appropriate safety gear (e.g., gloves, eye protection)

- Keep the work area clean and free of debris

- Follow established safety protocols for machine operation

6. What is the importance of proper maintenance of header machines?

- Ensures optimal machine performance and efficiency

- Reduces downtime and repair costs

- Enhances safety and reduces the risk of accidents

7. Describe the different types of header dies used in header machines?

Cold Header Dies

- Forward extrusion dies

- Backward extrusion dies

Hot Header Dies

- Open dies

- Closed dies

8. How do you determine the appropriate header die for a specific application?

- Consider the type of header being produced

- Evaluate the material properties and dimensions

- Assess the machine capabilities

9. What is the role of a header die engineer in the header machine operation?

- Design and develop header dies

- Troubleshoot and resolve die-related issues

- Provide technical support to header machine operators

10. How do you stay updated with the latest advances in header machine technology?

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Engage with colleagues and experts in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Header Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Header Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Header Machine Operators play a crucial role in the production process by operating and maintaining header machines used to create fasteners, rivets, and other metal components. Their primary responsibilities include:

1. Machine Operation

Operate header machines to produce metal components according to specifications.

- Set up and adjust machines for different production runs.

- Load and unload raw materials and finished products.

2. Quality Control

Inspect components to ensure they meet quality standards.

- Use measuring tools and gauges to check dimensions and tolerances.

- Identify and correct defects in components.

3. Machine Maintenance

Perform basic maintenance and troubleshooting on header machines.

- Clean and lubricate machines.

- Replace worn or damaged parts.

4. Safety

Follow safety protocols to ensure a safe work environment.

- Wear appropriate safety gear, including earplugs and safety glasses.

- Operate machines safely and maintain a clean work area.

Interview Tips

Preparing for a Header Machine Operator interview requires understanding the job’s responsibilities and showcasing relevant skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Position

Read the job description thoroughly and research the company to gain insight into their products, culture, and values. This knowledge will help you tailor your responses to the specific requirements of the role.

2. Highlight Relevant Skills

Focus on highlighting skills that are essential for Header Machine Operators, such as attention to detail, mechanical aptitude, and problem-solving abilities. Provide specific examples from your previous work experience that demonstrate your proficiency in these areas.

3. Practice Common Interview Questions

Prepare for common interview questions related to your work experience, technical skills, and safety knowledge. Practice answering these questions concisely and confidently, using the STAR method (Situation, Task, Action, Result) to provide detailed examples.

4. Ask Thoughtful Questions

Asking insightful questions at the end of the interview shows your interest in the position and the company. Prepare thoughtful questions about the production process, safety protocols, or growth opportunities within the organization.

5. Dress Professionally

First impressions matter, so dress professionally for the interview. This could include a button-down shirt or blouse, slacks, and closed-toe shoes.

6. Be Enthusiastic and Positive

Throughout the interview, maintain a positive attitude and show enthusiasm for the opportunity. Your passion for the field and willingness to learn will be evident to the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Header Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!