Are you gearing up for an interview for a Header Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Header Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

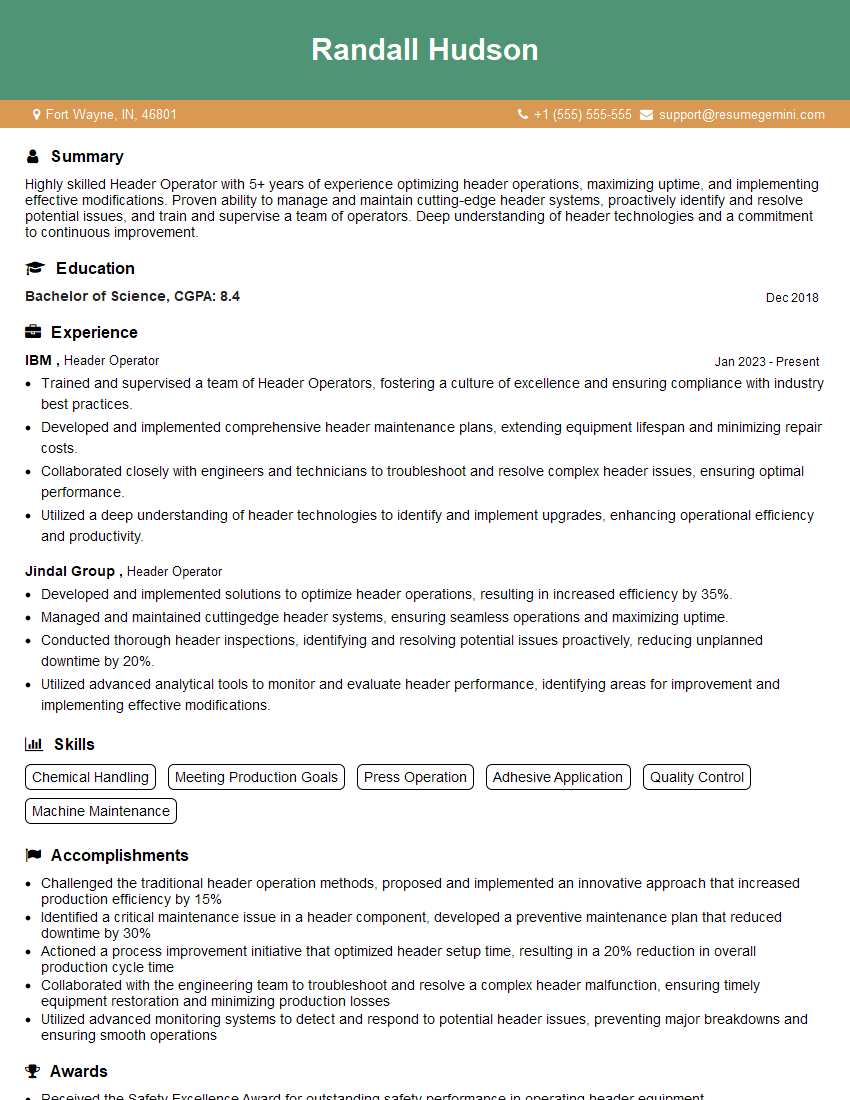

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Header Operator

1. Describe your experience with Header machine?

In my previous role, I was the primary operator of a Header machine responsible for processing large volumes of raw material. My responsibilities included:

- Setting up and calibrating the machine according to production specifications.

- Monitoring the header process and making adjustments as needed.

- Identifying and correcting any malfunctions or issues with the machine promptly.

- Maintaining a clean and safe work environment around the machine.

2. Explain the process of adjusting header machine?

Checking belt tension

- Ensure proper tension to avoid slipping or breakage during operation.

Adjusting cutter blades

- Set the blades to the correct height and angle for clean and precise cutting.

- Calibrate the blade angle to maintain the desired header cut length.

Adjusting feed rate

- Control the speed at which the crop is fed into the machine.

- Optimize the feed rate to maximize efficiency while preventing blockages.

Adjusting header height

- Set the header height to match the crop level.

- Ensure proper header-to-ground clearance to prevent damage to the machine or crop.

3. How do you maintain performance logs for the header machine?

I maintain performance logs to track the machine’s efficiency, identify areas for improvement, and ensure optimal operation:

- Log daily production output, including the number of acres harvested.

- Record machine parameters such as belt tension, blade settings, and feed rate.

- Note any maintenance performed, including repairs or replacements.

- Document any downtime, including the cause and duration.

- Review logs regularly to identify trends and make adjustments as needed.

4. What are the safety precautions to follow when operating a Header machine?

I strictly adhere to the following safety precautions for the safe operation of a Header machine:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and earplugs.

- Inspect the machine thoroughly before each use, checking for any damage or loose parts.

- Ensure the machine is properly grounded to prevent electrical hazards.

- Be aware of the surrounding environment, including obstacles and personnel.

- Never attempt to clear blockages or make adjustments while the machine is running.

- Follow proper lockout/tagout procedures before performing maintenance or repairs.

- Report any safety concerns or incidents promptly to the supervisor.

5. How do you troubleshoot common issues with Header machine?

I am well-versed in troubleshooting common issues with Header machines, including:

- Clogged header: Adjust the feeder settings, check for blockages, and clean the machine thoroughly.

- Uneven cut: Calibrate the cutter blades, check for worn or damaged blades, and adjust the header height.

- Excessive vibration: Inspect the belts, bearings, and cutter blades for damage or wear, and ensure proper tension.

- Electrical problems: Check connections, fuses, and wiring for damage, and refer to the manufacturer’s manual for troubleshooting steps.

- Hydraulic leaks: Inspect hoses, fittings, and seals for leaks, and follow proper procedures for repairing or replacing them.

6. How do you ensure the quality of the harvested crop?

I take the following steps to ensure the quality of the harvested crop:

- Set and adjust the header height to minimize ground contamination.

- Maintain sharp cutter blades to achieve clean cuts and prevent crop damage.

- Monitor the feed rate to avoid overloading the machine and ensure proper threshing.

- Inspect the harvested crop regularly for any signs of damage or contamination.

- Follow established protocols for cleaning and maintaining the header machine.

7. What knowledge do you have about different types of headers?

I am familiar with various types of headers used in agriculture, including:

- Grain headers: Designed for harvesting grains such as wheat, barley, and oats.

- Corn headers: Specifically used for harvesting corn, with features such as stalk rollers and snapping heads.

- Soybean headers: Equipped with flexible draper belts to minimize pod shattering during soybean harvesting.

- Sunflower headers: Customized for sunflower harvesting, with special cutter bars and seed-saving devices.

- Canola headers: Designed to handle the unique characteristics of canola plants, employing wide cutter bars and windrow attachments.

8. How do you handle working in a team environment?

I am an effective team player and thrive in collaborative environments. My approach to teamwork involves:

- Communicating clearly and effectively with team members.

- Respecting and valuing diverse perspectives and experiences.

- Contributing to team goals and objectives.

- Providing support and assistance to colleagues.

- Maintaining a positive and professional attitude.

9. What are your expectations for this role?

My expectations for this role include:

- Operating and maintaining the Header machine efficiently and safely.

- Meeting production targets and ensuring the quality of the harvested crop.

- Working effectively within a team environment.

- Participating in training and development opportunities.

- Contributing to the overall success of the organization.

10. Why are you interested in joining our organization?

I am eager to join your organization because:

- I am impressed by your reputation as a leader in the agricultural industry.

- I am confident that my skills and experience would be a valuable asset to your team.

- I am excited about the opportunity to contribute to your company’s success.

- I am keen on learning from experienced professionals and expanding my knowledge in the industry.

- I am eager to work in a dynamic and challenging environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Header Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Header Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Header Operator plays a crucial role in the production process by operating and monitoring header equipment responsible for separating liquids and gases from oil.

1. Operating Header Equipment

The Header Operator is responsible for the safe and efficient operation of header equipment, including:

- Monitoring and controlling pressure, temperature, and flow rates

- Adjusting valves and gauges to optimize performance

- Identifying and troubleshooting equipment malfunctions

2. Maintaining Header Equipment

The operator ensures that header equipment is properly maintained to prevent breakdowns and ensure optimal performance. This includes:

- Performing routine inspections and maintenance checks

- Identifying and repairing worn or damaged components

- Maintaining proper lubrication and cleaning of equipment

3. Monitoring Production and Quality

The Header Operator closely monitors the production process to ensure that the oil meets the desired quality standards. Responsibilities include:

- Taking samples and conducting tests to analyze oil quality

- Identifying and addressing any deviations from quality specifications

- Reporting production data and quality issues to supervisors

4. Safety and Compliance

Safety is paramount for a Header Operator. Responsibilities include:

- Following established safety protocols and procedures

- Identifying and reporting potential hazards

- Using personal protective equipment (PPE) appropriately

Interview Tips

Interview preparation is essential to impress hiring managers and land your dream job as a Header Operator. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the company’s operations, history, and industry trends. Be prepared to discuss how your skills and experience align with the company’s needs.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Rehearse your responses to highlight your relevant skills and experience.

3. Technical Expertise

Be confident in discussing your technical expertise in header operations. Prepare to discuss your experience with different types of header equipment and your troubleshooting skills.

4. Safety Emphasis

Emphasize your commitment to safety. Provide examples of how you have implemented safety measures in previous roles and explain how you prioritize safety in your work.

5. Attention to Detail

Highlight your attention to detail and ability to identify and resolve quality issues. Share examples of how you have ensured the quality of oil production in previous positions.

6. Teamwork and Communication

Discuss your teamwork and communication skills. Explain how you collaborate effectively with others and clearly communicate information to supervisors and team members.

7. Motivation and Drive

Explain what motivates you in your work and demonstrate your drive to succeed. Provide examples of how you have overcome challenges and achieved results.

8. Dress Professionally and Arrive Punctually

Make a good impression by dressing professionally and arriving for the interview on time. This shows respect for the interviewers and indicates your punctuality.

9. Ask Thoughtful Questions

Prepare intelligent questions to ask the interviewers. This shows your interest in the position and the company and allows you to gauge if the role is a good fit.

10. Follow Up

After the interview, send a thank-you note to the interviewers. This is an opportunity to reiterate your interest in the position and thank them for their time.

Next Step:

Now that you’re armed with the knowledge of Header Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Header Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini