Are you gearing up for an interview for a Heading Saw Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Heading Saw Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

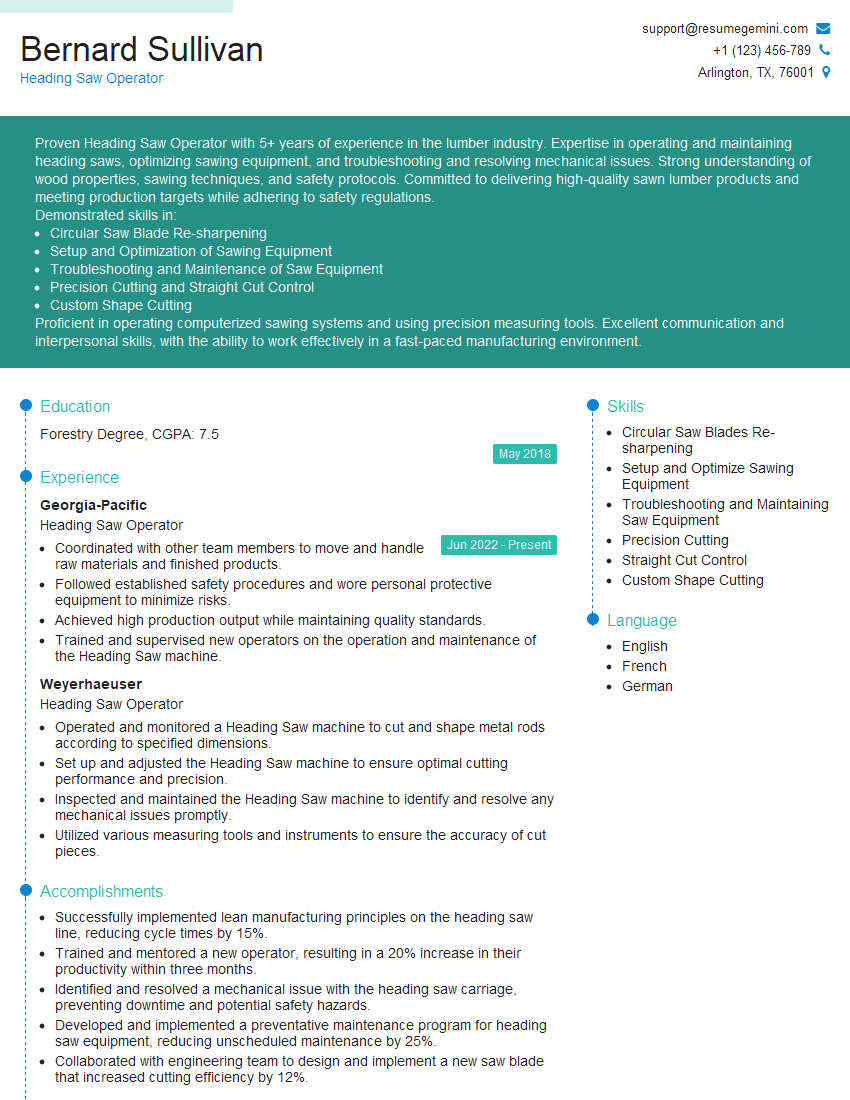

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heading Saw Operator

1. What are the key responsibilities of a Heading Saw Operator?

As a Heading Saw Operator, I would be responsible for the safe and efficient operation of the heading saw, ensuring that the produced headings meet the required specifications.

- Setting up and operating the heading saw to cut heads from steel bars or rods.

- Monitoring the saw’s operation, including blade speed, feed rate, and coolant flow.

- Measuring and inspecting the finished heads to ensure they meet the specified dimensions and tolerances.

- Performing regular maintenance and cleaning of the saw to maintain its optimal performance.

- Following safety protocols and using proper personal protective equipment (PPE).

2. How do you ensure the accuracy and quality of the cut heads?

Measuring and Inspection Techniques

- Utilizing precision measuring tools, such as calipers and micrometers, to verify the dimensions of the cut heads.

- Employing visual inspection methods to check for any defects or imperfections in the cut.

- Performing quality control checks throughout the cutting process to identify and correct any deviations from the specifications.

Saw Maintenance and Calibration

- Regularly inspecting and maintaining the saw’s blades, ensuring they are sharp and properly aligned.

- Calibrating the saw to ensure accurate cutting angles and dimensions.

- Monitoring and adjusting the saw’s feed rate and cutting parameters to optimize performance.

3. What troubleshooting steps would you take if the saw is not cutting straight?

To troubleshoot a heading saw that’s not cutting straight, I would follow a systematic approach:

- Check the saw blade for any damage or misalignment, and replace or adjust it if necessary.

- Inspect the saw’s feed mechanism to ensure it’s operating smoothly and feeding the material evenly.

- Verify that the saw’s fence is properly aligned and secure.

- Adjust the saw’s cutting parameters, such as blade speed and feed rate, to optimize the cut.

- If the issue persists, I would refer to the saw’s maintenance manual or consult with a qualified technician.

4. How do you maintain the saw and ensure its longevity?

To maintain the heading saw and ensure its longevity, I would adhere to the following practices:

- Regularly clean and lubricate the saw’s moving parts to minimize friction and wear.

- Inspect and sharpen the saw blade regularly to maintain its cutting efficiency.

- Check and adjust the saw’s tension to prevent blade breakage.

- Monitor the saw’s coolant system to ensure it’s functioning properly and supplying adequate lubrication.

- Follow the manufacturer’s recommended maintenance schedule for periodic inspections and overhauls.

5. How do you handle different types of materials and their cutting requirements?

When working with different types of materials, I adjust my cutting techniques to suit their specific properties:

- Ferrous materials: Use high-speed steel (HSS) or carbide-tipped blades for clean and precise cuts.

- Non-ferrous materials: Employ non-ferrous specific blades to prevent material buildup and ensure a smooth finish.

- Hardened materials: Utilize specialized blades designed for cutting hardened materials, such as diamond-tipped blades.

- Thin materials: Employ thin blades with minimal set to avoid material distortion.

- Thick materials: Use blades with a wider set and slower feed rates to handle thicker materials effectively.

6. How do you ensure safety while operating the heading saw?

Safety is paramount when operating a heading saw. I strictly adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Ensure the saw is properly grounded and all electrical connections are secure.

- Keep the work area clean and free from tripping hazards.

- Securely clamp the material before cutting to prevent it from moving.

- Never attempt to cut materials that are too large or heavy for the saw’s capacity.

- Follow proper lockout/tagout procedures when performing maintenance or repairs.

7. How do you calculate the correct blade speed for different materials?

To determine the appropriate blade speed for various materials, I use the following formula:

- Blade Speed (SFM) = Cutting Speed (FPM) x Pi (3.14) x Blade Diameter (inches)

I refer to cutting speed charts that provide recommended values for different materials. For example:

- Mild steel: 100-200 FPM

- Stainless steel: 50-100 FPM

- Aluminum: 200-400 FPM

8. What techniques do you use to maximize the lifespan of saw blades?

To prolong the lifespan of saw blades, I employ the following techniques:

- Use the correct blade for the material being cut.

- Sharpen blades regularly to maintain their cutting edge.

- Set the proper blade tension to prevent breakage.

- Avoid cutting through non-ferrous materials, which can damage the blade.

- Store blades in a dry and protected location.

- Inspect blades for damage before each use.

9. How do you troubleshoot common problems encountered with heading saws?

When troubleshooting heading saw issues, I follow a systematic approach:

- Blade vibration: Check for blade damage, misalignment, or improper tension.

- Poor cut quality: Inspect blade sharpness, cutting speed, and feed rate. Adjust accordingly.

- Saw overheating: Ensure proper coolant flow and lubrication. Check for excessive friction.

- Motor problems: Verify power supply, check for overheating, and inspect motor brushes.

- Hydraulic issues: Check hydraulic fluid levels, inspect hoses and seals for leaks.

10. How do you stay updated with the latest advancements in heading saw technology?

To keep abreast of the latest advancements in heading saw technology, I:

- Attend industry conferences and exhibitions.

- Read trade publications and technical articles.

- Consult with saw manufacturers and industry experts.

- Participate in online forums and discussion groups.

- Stay informed about new products, materials, and techniques through research and networking.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heading Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heading Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heading Saw Operators are responsible for operating heading saws to cut metal stock into various shapes and sizes. They set up and adjust the saw according to specifications, and they monitor the cutting process to ensure that it is running smoothly and producing quality cuts. They also perform maintenance on the saw and its components to keep it in good working order. Additionally, they may be responsible for training new employees and overseeing the work of other saw operators.

1. Set up and adjust the saw

Heading Saw Operators must be able to set up and adjust the saw according to specifications. This includes setting the blade height, blade angle, and feed rate. They must also be able to adjust the saw to cut different types of metal stock and to produce different shapes and sizes of cuts.

- Set the blade height to the desired cut depth.

- Set the blade angle to the desired cut angle.

- Set the feed rate to the desired cutting speed.

- Adjust the saw to cut different types of metal stock.

- Adjust the saw to produce different shapes and sizes of cuts.

2. Monitor the cutting process

Heading Saw Operators must be able to monitor the cutting process to ensure that it is running smoothly and producing quality cuts. They must be able to identify and correct any problems that may occur during the cutting process.

- Monitor the cutting process to ensure that it is running smoothly.

- Identify and correct any problems that may occur during the cutting process.

3. Perform maintenance on the saw and its components

Heading Saw Operators must be able to perform maintenance on the saw and its components to keep it in good working order. This includes cleaning, lubricating, and adjusting the saw. They must also be able to identify and replace worn or damaged parts.

- Clean the saw and its components.

- Lubricate the saw and its components.

- Adjust the saw and its components.

- Identify and replace worn or damaged parts.

4. Train new employees and oversee the work of other saw operators

Heading Saw Operators may be responsible for training new employees and overseeing the work of other saw operators. They must be able to provide clear and concise instructions and they must be able to answer any questions that new employees or other saw operators may have.

- Provide clear and concise instructions to new employees.

- Answer any questions that new employees or other saw operators may have.

- Oversee the work of other saw operators.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. By following these tips, you can make a great impression on the interviewer and land the job you want.

1. Research the company and the position

Before you go to an interview, it’s important to do your research. Learn as much as you can about the company and the position you’re applying for. This will help you answer questions intelligently and show the interviewer that you’re genuinely interested in the opportunity.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work for the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Prepare for behavioral questions.

- Practice your answers with a friend or family member.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This will show the interviewer that you’re respectful of their time.

- Choose appropriate interview attire.

- Arrive on time for your interview.

4. Be yourself and be enthusiastic

The most important thing is to be yourself and be enthusiastic about the opportunity. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. And if you’re excited about the position, let the interviewer know.

- Be yourself during the interview.

- Show the interviewer that you’re enthusiastic about the opportunity.

Next Step:

Now that you’re armed with the knowledge of Heading Saw Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Heading Saw Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini