Are you gearing up for a career in Heat Set Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Heat Set Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

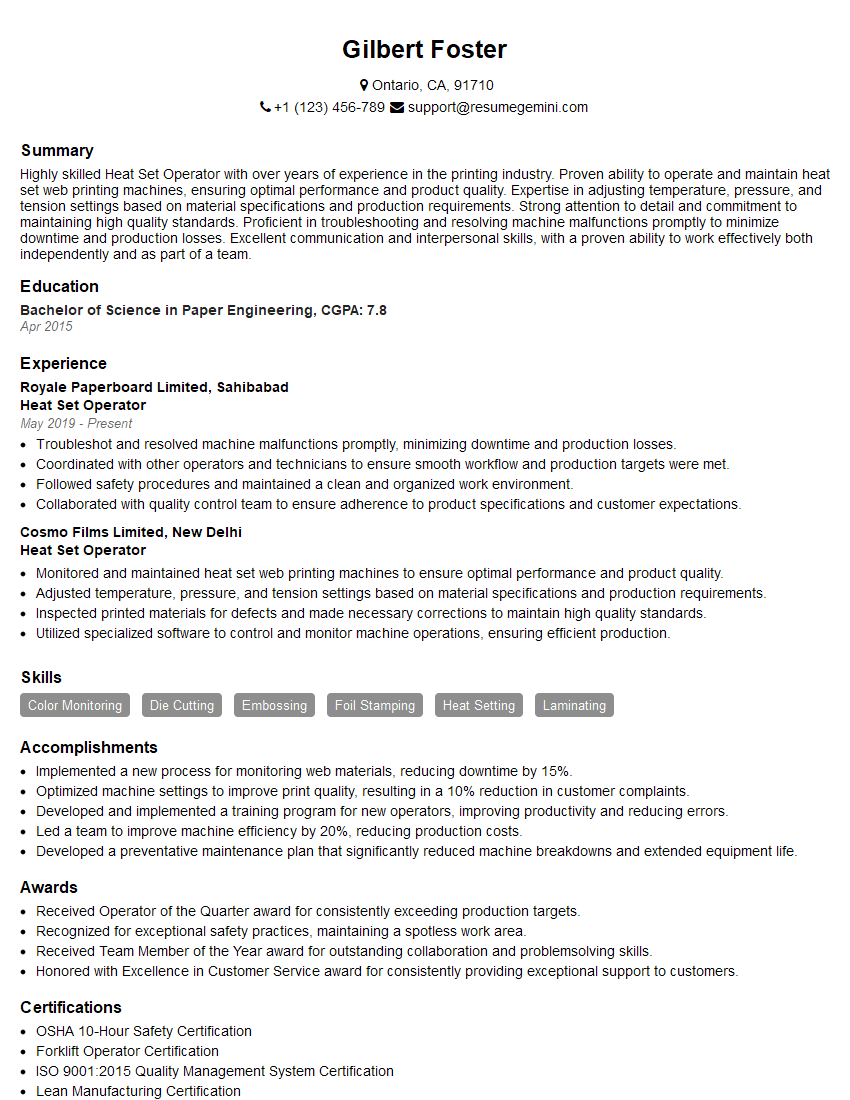

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Set Operator

1. What are the key responsibilities of a Heat Set Operator?

As a Heat Set Operator, my primary responsibilities include:

- Operating and monitoring heat set equipment to ensure proper drying and curing of print materials

- Controlling variables such as temperature, speed, and tension to maintain product quality

2. Describe the different types of heat set equipment you have experience with?

Web offset presses

- Understand the principles of web offset printing

- Operate and maintain web offset heat set units

Sheetfed presses

- Operate and maintain sheetfed heat set units

- Monitor and control temperature and speed to ensure proper curing

3. How do you troubleshoot common problems that arise with heat set equipment?

I troubleshoot common problems by:

- Identifying the symptoms of the problem

- Checking the equipment for any obvious issues

- Consulting the manufacturer’s manual or consulting with a supervisor

- Taking steps to resolve the problem, such as adjusting settings or replacing parts

4. What are the safety precautions that must be taken when operating heat set equipment?

To ensure safety, I adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE)

- Following lock-out/tag-out procedures when servicing equipment

- Being aware of potential hazards, such as hot surfaces and moving parts

- Reporting any unsafe conditions or practices to a supervisor

5. How do you monitor and control the quality of the finished product?

I monitor and control quality by:

- Visually inspecting the finished product for defects

- Using measuring devices to ensure that the product meets specifications

- Making adjustments to the equipment or process as needed

- Documenting quality control data and reporting any issues to a supervisor

6. What is your experience with different types of inks and coatings used in heat set printing?

I have experience with a variety of inks and coatings, including:

- Heatset inks: understand their properties and how to adjust equipment to optimize their performance

- UV coatings: know their application methods and safety precautions

- Water-based coatings: familiar with their environmental benefits and handling requirements

7. How do you maintain and calibrate heat set equipment to ensure optimal performance?

To maintain and calibrate equipment, I perform the following tasks:

- Regularly cleaning and lubricating equipment

- Performing preventive maintenance according to manufacturer’s guidelines

- Using calibration tools and procedures to ensure accuracy

- Documenting maintenance and calibration activities

8. What is your understanding of the environmental regulations related to heat set printing?

I am aware of environmental regulations related to heat set printing, including:

- Air quality regulations: understand the requirements for controlling emissions

- Waste management regulations: know how to properly dispose of hazardous materials

- Energy efficiency standards: familiar with measures to reduce energy consumption

9. How do you work effectively in a team environment with other operators and pressmen?

I am an effective team player and I work well with others by:

- Communicating clearly and effectively

- Cooperating with others to achieve common goals

- Supporting team members and providing assistance when needed

- Maintaining a positive and professional attitude

10. Describe a time when you faced a challenging situation related to heat set printing and how you overcame it.

Once, I encountered a problem where the heat set oven was not heating evenly, resulting in inconsistent product quality. I promptly:

- Troubleshooted the oven and identified a faulty temperature sensor

- Replaced the sensor and recalibrated the oven

- Monitored the oven’s performance and ensured that it was operating within specifications

- Documented the issue and the steps taken to resolve it

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Set Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Set Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heat Set Operators play a crucial role in the printing industry, ensuring the proper functioning of heat set printing machines. Their primary responsibilities include:

1. Machine Operation

Operate and maintain heat set printing machines, including setting up, adjusting, and monitoring their operation.

- Set printing speeds, paper feed rates, and temperature settings.

- Inspect and adjust printing plates and rollers to ensure optimal print quality.

2. Production Management

Monitor production processes, ensuring timely completion of print jobs and meeting quality standards.

- Troubleshoot and resolve any issues with the machine or the printing process.

- Coordinate with other departments, such as prepress and finishing, to ensure a smooth production flow.

3. Quality Control

Inspect printed materials to ensure they meet the required quality specifications.

- Identify and correct any printing defects or inconsistencies.

- Maintain quality records and report on production performance.

4. Maintenance and Repair

Perform routine maintenance and repairs on the heat set printing machine.

- Clean and lubricate machine components.

- Identify and replace worn or defective parts.

Interview Tips

To prepare effectively for a Heat Set Operator interview, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and industry standing. Understand the specific responsibilities and requirements of the Heat Set Operator role.

- Visit the company website and review their mission statement, values, and recent news.

- Examine the job description thoroughly, identifying the key skills and qualifications required.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating heat set printing machines and your understanding of the printing process. Showcase any experience in troubleshooting, quality control, and maintenance.

- Quantify your accomplishments by providing specific examples of how you have contributed to successful printing operations.

- Be prepared to discuss your experience with different types of printing materials, such as paper, plastic, and metal.

3. Demonstrate Problem-Solving Abilities

Interviews often involve questions designed to assess your problem-solving skills. Prepare anecdotes that illustrate your ability to identify and resolve issues quickly and efficiently.

- Recall a time when you encountered a technical problem with a printing machine and describe the steps you took to solve it.

- Explain how you prioritize and manage multiple tasks in a fast-paced production environment.

4. Prepare for Technical Questions

Expect questions related to the technical aspects of heat set printing. Be prepared to discuss topics such as ink viscosity, paper grain, and temperature control.

- Review the basics of heat set printing technology and familiarize yourself with industry terminology.

- Practice explaining technical concepts in a clear and concise manner.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Heat Set Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.