Are you gearing up for a career in Heat Treat Furnace Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Heat Treat Furnace Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

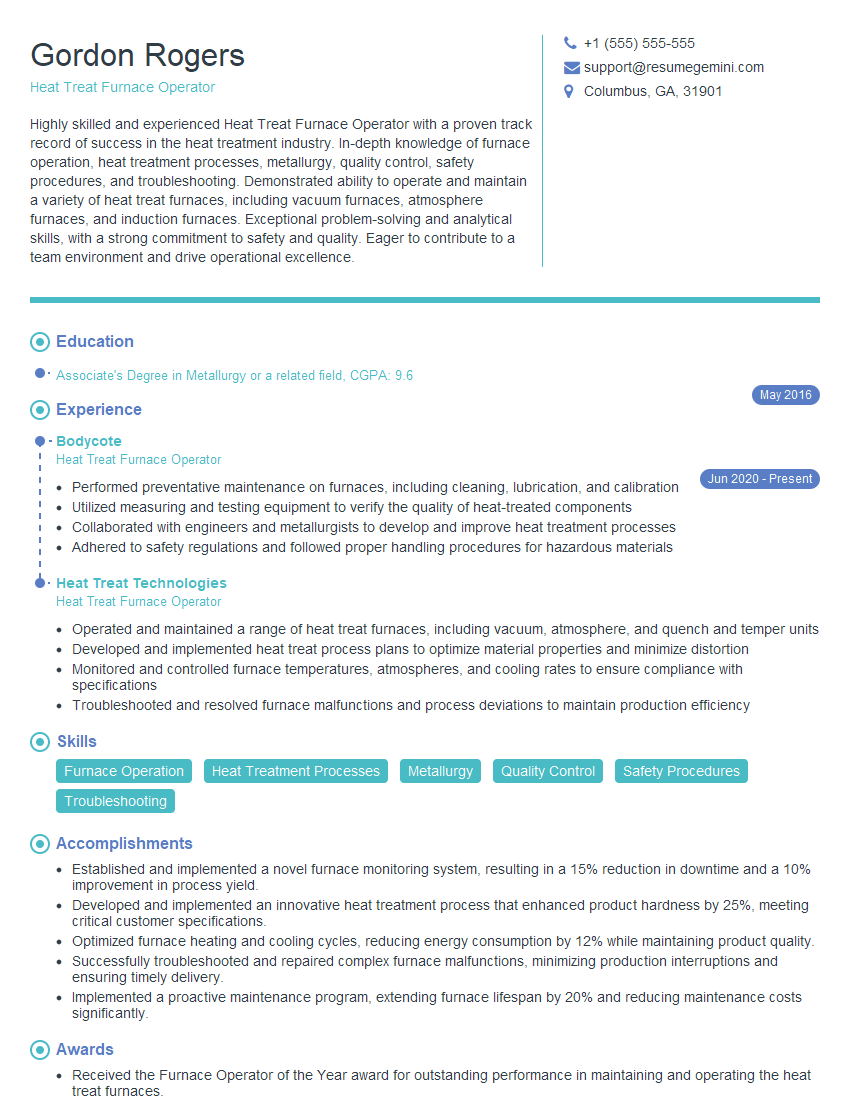

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Treat Furnace Operator

1. What are the different types of heat treat furnaces and what are their respective applications?

There are various types of heat treat furnaces, each with its own applications. Some common types include:

- Batch furnaces: Used for heating and cooling large quantities of parts in a single batch.

- Continuous furnaces: Parts move through the furnace on a conveyor, allowing for high-volume production.

- Vacuum furnaces: Used for heating and cooling parts in a vacuum environment, reducing contamination and oxidation.

- Atmosphere-controlled furnaces: Controls the furnace atmosphere to achieve specific material properties.

- Induction furnaces: Uses electromagnetic induction to heat conductive materials.

2. Explain the principles of heat transfer in heat treat furnaces.

Heat transfer in heat treat furnaces involves three main mechanisms:

- Convection: Heat transfer between a fluid and a solid surface.

- Radiation: Heat transfer through electromagnetic waves.

- Conduction: Heat transfer between two solids in contact.

Furnace design and operating parameters influence the rate and efficiency of heat transfer.

3. Describe the different types of thermocouples used in heat treat furnaces and their applications.

Thermocouples are used to measure temperatures in heat treat furnaces. Common types include:

- Type K (Chromel-Alumel): Versatile and widely used, suitable for a wide temperature range.

- Type J (Iron-Constantan): Inexpensive and accurate at lower temperatures.

- Type S (Platinum-Platinum 10% Rhodium): High accuracy and stability, used for higher temperatures.

Proper thermocouple selection and placement are crucial for accurate temperature measurement and control.

4. Explain the purpose of quenching in heat treatment and describe the different quenching media used.

Quenching involves rapidly cooling a heated material to achieve desired properties:

- Hardenability: Increases the material’s hardness and strength.

- Microstructure control: Alters the material’s grain structure and phase transformations.

Common quenching media include:

- Water: Fastest cooling rate, but can cause distortion and cracking.

- Oil: Slower cooling rate, reducing distortion and cracking.

- Air: Slowest cooling rate, minimizing distortion and cracking.

5. Describe the annealing process in heat treatment and explain its benefits.

Annealing involves heating and slowly cooling a material to:

- Soften: Reduce hardness and increase ductility.

- Relieve stresses: Remove internal stresses introduced during manufacturing or previous heat treatments.

- Improve machinability: Make the material easier to cut and shape.

Annealing is commonly used in various industries, such as automotive, aerospace, and metalworking.

6. Explain the tempering process in heat treatment and describe its effects on material properties.

Tempering involves reheating quenched steel to a lower temperature to:

- Reduce hardness and brittleness: Enhance toughness and ductility.

- Control mechanical properties: Tailor the material’s strength, hardness, and toughness based on the desired application.

Tempering is often used in conjunction with quenching to achieve specific material properties.

7. Describe the factors that affect the effectiveness of carburizing in heat treatment.

Carburizing involves adding carbon to the surface of a steel part to:

- Increase hardness: Improve wear resistance and surface durability.

- Reduce friction: Improve sliding and rolling contact performance.

Factors affecting carburizing effectiveness include:

- Carburizing atmosphere

- Temperature

- Time

- Steel composition

8. Explain the nitriding process in heat treatment and describe its applications.

Nitriding involves introducing nitrogen into the surface of a steel part to:

- Increase hardness and wear resistance: Enhance surface durability and reduce friction.

- Improve corrosion resistance: Protect against oxidation and chemical attack.

Nitriding is used in various applications, including:

- Automotive components

- Aerospace components

- Medical devices

9. Describe the safety precautions that must be followed when operating a heat treat furnace.

- Wearing appropriate personal protective equipment (PPE)

- Following proper ventilation procedures

- Handling hazardous materials safely

- Monitoring furnace temperature and atmosphere closely

- Being aware of potential hazards, such as fire, explosions, and burns

10. Explain how you would troubleshoot a heat treat furnace that is not heating properly.

- Check the power supply and electrical connections

- Inspect the heating elements for damage or failure

- Verify the temperature controller and thermocouple are functioning correctly

- Check for any blockages or airflow issues in the furnace

- Run diagnostic tests and consult the manufacturer’s guidelines

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Treat Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Treat Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heat Treat Furnace Operators are responsible for the safe and efficient operation of furnaces used to heat treat metal components. They must have a strong understanding of the heat treatment process and how to operate and maintain furnaces. Key job responsibilities include:

1. Furnace Operation

Operators are responsible for setting up and operating furnaces to achieve the desired heat treatment results. They must be able to monitor and control furnace temperatures, pressures, and other process parameters.

- Set up and operate furnaces according to specifications

- Monitor and control furnace temperatures, pressures, and other process parameters

- Adjust furnace settings to achieve desired heat treatment results

2. Quality Control

Operators are responsible for ensuring that heat treated components meet quality standards. They must be able to inspect components for defects and perform quality control tests.

- Inspect components for defects

- Perform quality control tests

- Maintain quality control records

3. Maintenance

Operators are responsible for performing routine maintenance on furnaces. They must be able to identify and troubleshoot problems and perform repairs. Also they must maintain a clean and safe work area.

- Lubricate moving parts

- Inspect furnace components for wear and tear

- Replace worn or damaged parts

- Perform preventative maintenance

- Maintain a clean and safe work area

4. Safety

Operators must be aware of the potential hazards associated with working with furnaces and must take appropriate safety precautions.

- Wear appropriate personal protective equipment

- Follow all safety procedures

- Identify and eliminate potential hazards

Interview Tips

Preparing for an interview for a Heat Treat Furnace Operator position requires researching the company, practicing your answers to common interview questions, and dressing professionally. Here are some additional tips to help you ace your interview:

1. Research the Company

Before the interview, take some time to learn about the company. This will help you understand their business, culture, and the specific role you are interviewing for. You can find information about the company on their website, social media pages, and news articles.

- Visit the company website

- Read the company’s social media pages

- Research the company on Google News

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Why should we hire you?

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

4. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be confident, and let your personality shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Heat Treat Furnace Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!