Feeling lost in a sea of interview questions? Landed that dream interview for Heat Treat Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Heat Treat Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

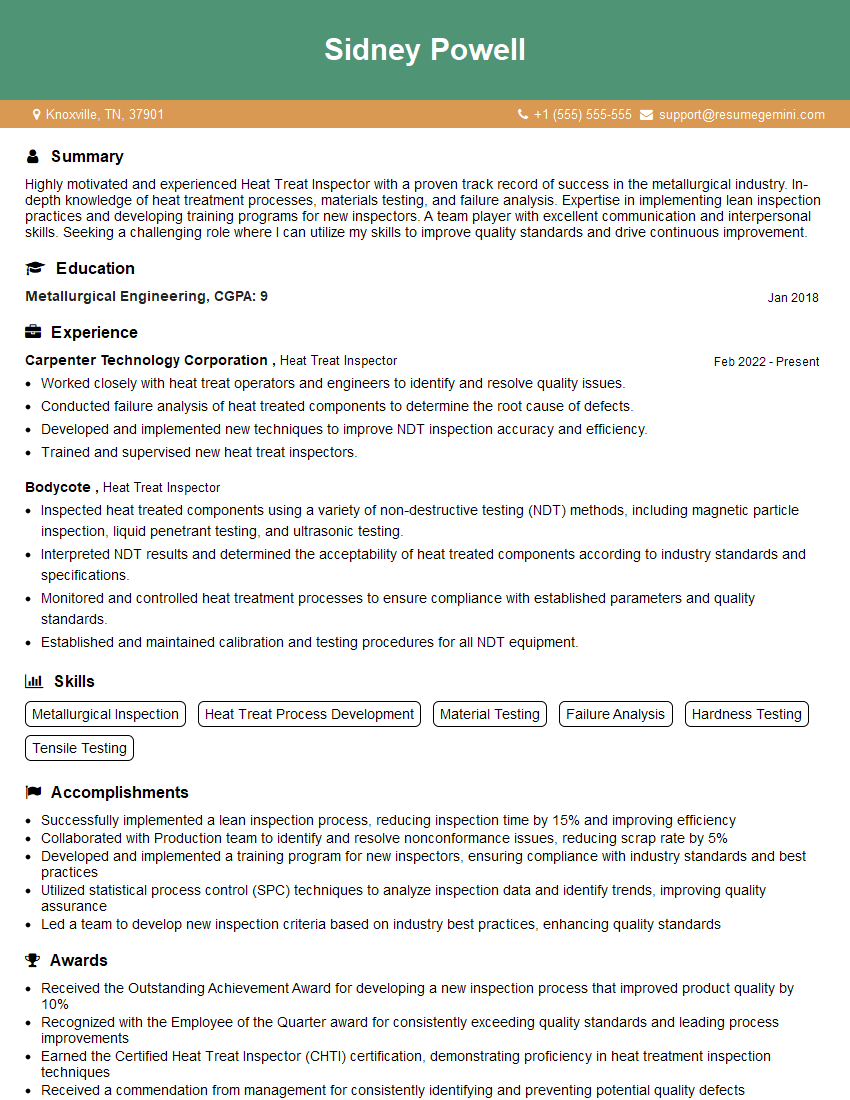

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Treat Inspector

1. How do you determine the appropriate heat treatment process for a given material?

The selection of the appropriate heat treatment process depends on several factors, including the material’s composition, desired properties, and specific application requirements. Here’s my approach:

- Identify the material’s composition and properties using material testing and specifications.

- Review process specifications, engineering drawings, and customer requirements to understand the desired properties.

- Consider the available heat treatment equipment and capabilities within the organization.

- Select the heat treatment process that best meets the desired properties while considering factors such as hardness, strength, toughness, and wear resistance.

- Establish process parameters and controls to ensure consistent and repeatable results.

2. What non-destructive testing (NDT) methods do you use to inspect heat-treated components?

Visual Inspection

- Inspect the component’s surface for defects such as cracks, scratches, or deformations.

- Utilize magnifying aids or borescopes for detailed examination of specific areas.

Magnetic Particle Inspection (MPI)

- Magnetize the component and apply magnetic particles to detect surface and near-surface cracks.

- Magnetic particle accumulations indicate the presence of discontinuities.

Penetrant Testing (PT)

- Apply a penetrant liquid to the component’s surface, allowing it to penetrate any discontinuities.

- Remove the excess penetrant and apply a developer, which draws the penetrant out of the discontinuities, making them visible.

Ultrasonic Testing (UT)

- Transmit ultrasonic waves through the component to detect internal defects such as inclusions, voids, or cracks.

- Analyze the reflected sound waves to determine the presence and location of discontinuities.

3. How do you interpret heat treatment charts and specifications?

To correctly interpret heat treatment charts and specifications, I follow these steps:

- Identify the material’s grade or alloy and its desired properties.

- Locate the appropriate heat treatment process and time-temperature parameters on the chart.

- Ensure that the specified heating and cooling rates are achievable with the available equipment.

- Determine the required holding times and cooling medium.

- Verify that the equipment is calibrated and capable of maintaining the specified parameters.

4. How do you ensure the accuracy and reliability of heat treatment equipment?

Maintaining the accuracy and reliability of heat treatment equipment is crucial. I follow these practices:

- Regularly calibrate temperature sensors, controllers, and recorders to ensure accurate temperature readings.

- Perform preventive maintenance on equipment, including cleaning, lubrication, and inspection.

- Monitor equipment performance during operation and record any deviations from specifications.

- Train operators on proper equipment usage and maintenance procedures.

- Establish and enforce quality control procedures to verify equipment functionality and accuracy.

5. What are the common defects associated with heat treatment, and how do you prevent them?

Common defects associated with heat treatment include:

- Warpage or Distortion: Prevent by using fixtures or supports, and controlling heating and cooling rates.

- Cracks: Prevent by selecting appropriate materials, avoiding sharp corners, and using preheating and post-heating techniques.

- Scale or Oxidation: Prevent by using protective atmospheres or salt baths during heat treatment.

- Decarburization: Prevent by controlling the atmosphere and temperature during heat treatment.

- Grain Growth: Prevent by using appropriate heating and cooling rates, and grain refiners in the material.

6. How do you handle non-conforming heat-treated components?

When non-conforming heat-treated components are detected, I follow these steps:

- Identify the non-conformance and determine its cause.

- Document the non-conformance and notify relevant parties.

- Segregate non-conforming components to prevent their release.

- Investigate the root cause of the non-conformance and implement corrective actions to prevent recurrence.

- Obtain approval from authorized personnel before reprocessing or scrapping non-conforming components.

7. How do you stay updated on the latest heat treatment technologies and best practices?

To stay updated on the latest heat treatment technologies and best practices, I engage in the following activities:

- Attend industry conferences, seminars, and webinars.

- Read technical publications and journals.

- Participate in professional organizations and networking events.

- Collaborate with heat treatment experts and researchers.

- Explore new equipment and technologies offered by manufacturers.

8. What are the safety precautions you observe when working with heat treatment equipment?

Safety is paramount in heat treatment operations. I strictly adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE) such as heat-resistant gloves, safety glasses, and protective clothing.

- Ensure proper ventilation and exhaust systems to remove fumes and gases.

- Guard against burns and fire hazards by using safe handling practices.

- Follow established safety protocols for handling and storing hazardous materials.

- Receive regular safety training and maintain awareness of potential risks.

9. How do you manage documentation and record-keeping related to heat treatment processes?

Effective documentation and record-keeping are crucial. I employ the following practices:

- Maintain accurate records of heat treatment parameters, including temperatures, times, and cooling methods.

- Document all inspections, tests, and non-conformances related to heat-treated components.

- Use a quality management system to track and retrieve documentation.

- Ensure document retention policies are followed to comply with industry standards and customer requirements.

- Provide clear and concise reports to stakeholders.

10. How do you collaborate with other departments within the organization to ensure the quality of heat-treated components?

Collaboration is essential for producing high-quality heat-treated components. I work closely with the following departments:

- Engineering: Review design specifications and provide input on heat treatment processes.

- Production: Coordinate heat treatment schedules and ensure proper handling of components.

- Quality Control: Participate in inspection and testing activities to verify compliance with specifications.

- Purchasing: Collaborate on material selection and ensure the availability of required materials.

- Maintenance: Work together to maintain and calibrate heat treatment equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Treat Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Treat Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heat Treat Inspectors play a critical role in ensuring the quality and reliability of metal components. Their primary responsibilities include:1. Verification and Inspection

Inspect and verify heat-treated components to ensure conformance to specifications and standards.

- Examine dimensions, finishes, and other physical characteristics using precision instruments.

- Utilize non-destructive testing methods (e.g., ultrasonic, magnetic particle) to detect defects.

2. Quality Control

Maintain high quality standards by monitoring and controlling heat treatment processes.

- Analyze data, identify process deviations, and recommend corrective actions.

- Record and document inspection results and quality control measures.

3. Technical Expertise

Possess a thorough understanding of heat treatment principles and metallurgy.

- Interpret technical drawings and specifications to ensure proper heat treatment parameters.

- Stay abreast of industry best practices and technological advancements.

4. Communication and Reporting

Effectively communicate inspection findings and quality control measures to stakeholders.

- Prepare inspection reports, summarize results, and provide recommendations.

- Interact with production personnel, engineers, and management to address quality concerns.

Interview Preparation Tips

To ace your Heat Treat Inspector interview, follow these essential tips:1. Research the Company and Industry

Thoroughly research the company’s history, products, and industry trends.

- This demonstrates your interest and commitment to the specific role.

- Example: “I understand that you specialize in high-performance aerospace components, and I’m eager to contribute my expertise in heat treatment for critical applications.”

2. Showcase Your Technical Proficiency

Highlight your in-depth knowledge of heat treatment processes and metallurgy.

- Quantify your experience and results to demonstrate your impact.

- Example: “In my previous role, I reduced defect rates by 20% by optimizing heat treatment parameters for aluminum alloy components.”

3. Discuss Quality Control and Process Improvement

Emphasize your commitment to quality control and process improvement initiatives.

- Explain specific methodologies you’ve implemented or recommendations you’ve made.

- Example: “I successfully implemented a Six Sigma project that improved the consistency and reliability of our heat treatment process, resulting in a 5% increase in product yield.”

4. Prepare for Technical Questions

Practice answering technical questions related to heat treatment and metallurgy.

- Review common industry standards and specifications (e.g., ASTM, MIL-STD).

- Example Question: “Describe the different types of heat treatment processes and their applications.”

5. Emphasize Communication and Interpersonal Skills

Highlight your ability to effectively communicate and collaborate with others.

- Share examples of how you’ve successfully communicated complex technical information to non-technical audiences.

- Example: “I’m confident in my ability to convey inspection findings and quality control measures to both production personnel and management.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Heat Treat Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!