Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Heat Treat Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Heat Treat Supervisor so you can tailor your answers to impress potential employers.

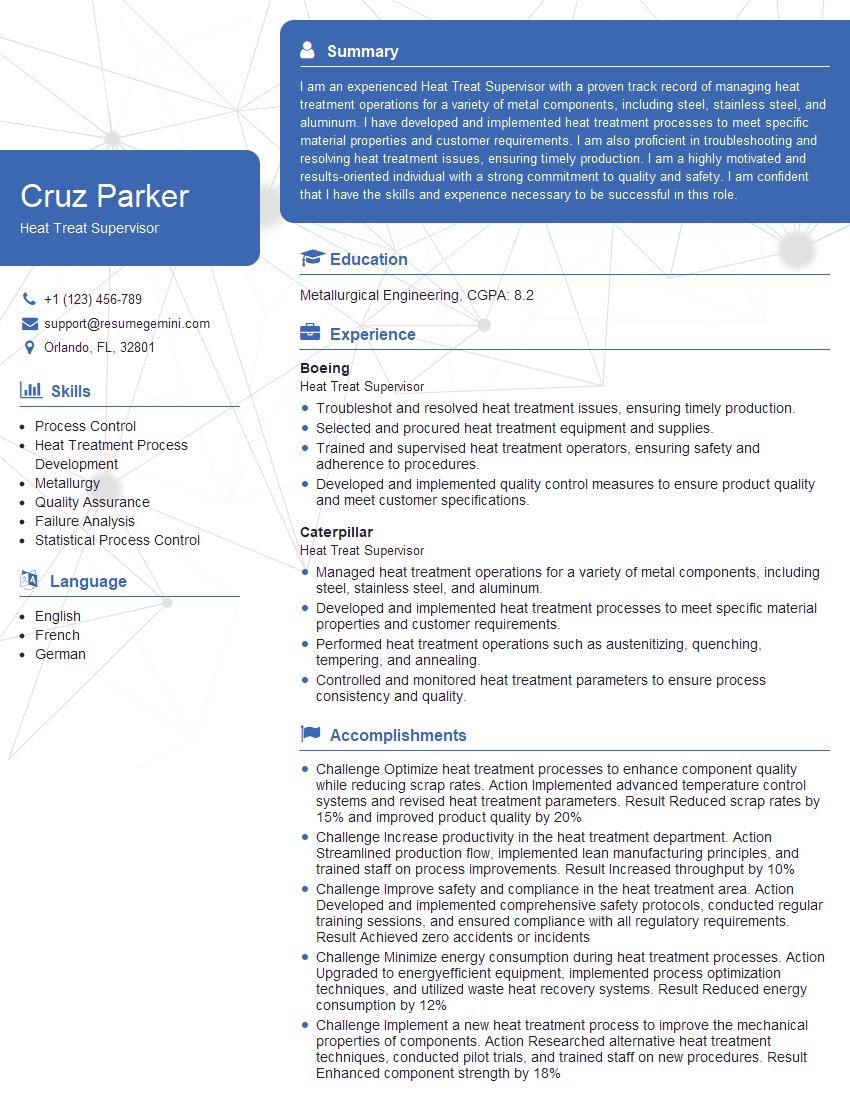

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Treat Supervisor

1. What are the different types of heat treatment processes that you are familiar with?

There are numerous heat treatment processes employed in the metalworking industry, each with its unique purpose and characteristics. Some of the commonly used methods include:

- Annealing: This process involves heating the metal to a specified temperature, holding it for a period of time, and then slowly cooling it to soften it and improve its machinability.

- Normalizing: This is a heat treatment technique that refines the grain structure of the metal, resulting in enhanced strength and toughness. It involves heating the metal above its critical temperature, holding it, and cooling it in still air.

- Hardening: This process is used to increase the hardness and wear resistance of a metal. It involves heating the metal to a high temperature, typically above its critical temperature, and then rapidly cooling it through a process called quenching.

- Tempering: This is a heat treatment step that follows hardening. It involves reheating the hardened metal to a specific temperature below its critical temperature, holding it, and then cooling it to reduce its hardness and brittleness while maintaining its strength.

- Carburizing: This process increases the carbon content of the metal’s surface, resulting in a harder and more wear-resistant surface. It involves exposing the metal to a carbon-rich atmosphere at high temperatures.

2. How do you determine the appropriate heat treatment process for a given material?

Factors to Consider

- The material’s composition and properties

- The desired mechanical properties (e.g., strength, hardness, toughness)

- The shape and size of the workpiece

- The equipment available

Process Selection

- Consult with material suppliers and heat treatment experts to gather data on the material’s response to different heat treatments.

- Conduct trial runs to determine the optimal process parameters for the specific application.

- Consider the cost, efficiency, and environmental impact of various heat treatment options.

3. What are some of the common defects that can occur during heat treatment, and how can they be prevented?

- Warping: Occurs when the metal is not heated evenly or cooled too quickly. Prevented by using proper heating techniques, fixturing, and controlled cooling rates.

- Cracking: Caused by excessive stresses induced during heating or cooling. Prevented by ensuring uniform heating, slow cooling, and using stress-relieving techniques.

- Scale formation: Occurs when the metal reacts with oxygen at high temperatures. Prevented by using controlled atmospheres, protective coatings, or vacuum heat treatment.

- Decarburization: Loss of carbon from the surface of the metal due to exposure to oxidizing environments. Prevented by using carburizing or nitriding processes, or by using protective atmospheres.

- Grain growth: Occurs when the metal is heated to excessively high temperatures or held at high temperatures for extended periods. Prevented by controlling the heating temperature and duration.

4. What is the importance of quality control in heat treatment?

- Ensures that the heat-treated parts meet the desired specifications and performance requirements.

- Minimizes the risk of defects and failures, reducing production costs and improving customer satisfaction.

- Maintains consistency in the quality of heat-treated parts, ensuring reliability and safety.

- Facilitates traceability and documentation, allowing for effective problem-solving and continuous improvement.

- Complies with industry standards and regulations, ensuring legal compliance and market acceptance.

5. How do you manage a team of heat treat operators?

Leadership and Motivation

- Provide clear instructions and expectations.

- Foster a positive and collaborative work environment.

- Recognize and reward employee contributions.

Training and Development

- Ensure that operators have the necessary skills and knowledge.

- Provide ongoing training to enhance their capabilities.

- Encourage professional development and certification.

Safety and Compliance

- Enforce strict adherence to safety protocols.

- Regularly inspect equipment and work areas.

- Comply with all applicable regulations and industry standards.

6. What are the emerging trends in heat treatment technology?

- Advanced heating technologies: Induction heating, laser heating, and microwave heating offer faster and more precise heating methods.

- Computer modeling and simulation: Enables optimization of heat treatment processes and prediction of material properties.

- Automated systems: Robotic handling and data acquisition systems improve efficiency and reduce human error.

- Environmentally friendly processes: Vacuum heat treatment and low-pressure carburizing reduce emissions and energy consumption.

- Additive manufacturing: Heat treatment plays a crucial role in post-processing of additively manufactured parts for enhanced mechanical properties.

7. What are the key challenges you have faced in your previous heat treatment roles, and how did you overcome them?

In my previous role as Heat Treat Supervisor at [Company Name], I encountered several challenges that required innovative solutions:

- Inconsistent heat treatment results: I implemented a comprehensive quality control system, standardized operating procedures, and conducted regular audits to identify and eliminate sources of variation.

- Equipment downtime: I established a proactive maintenance schedule, trained operators on preventive maintenance tasks, and partnered with equipment suppliers for timely support.

- Skill shortages: I developed a comprehensive training program and partnered with local educational institutions to attract and develop skilled heat treat operators.

- Environmental compliance: I implemented environmentally friendly heat treatment processes, reduced emissions, and ensured compliance with all applicable regulations.

- Customer complaints: I established a robust customer feedback system, analyzed complaints thoroughly, and implemented corrective actions to prevent recurrence.

8. How do you stay up-to-date with the latest advancements in heat treatment technology?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Network with other heat treatment professionals.

- Engage in research and development projects.

9. What are your strengths and weaknesses as a Heat Treat Supervisor?

Strengths

- Strong technical knowledge of heat treatment processes.

- Excellent problem-solving and analytical skills.

- Proven ability to lead and motivate a team.

- Excellent communication and interpersonal skills.

- Commitment to quality and continuous improvement.

Weaknesses

- Limited experience with certain specialized heat treatment techniques (e.g., vacuum heat treatment).

- Can be overly detail-oriented at times, leading to potential delays in decision-making.

10. Why are you interested in this Heat Treat Supervisor position at our company?

- Your company has a reputation for producing high-quality heat-treated products.

- I am impressed by your commitment to innovation and continuous improvement.

- I believe that my skills and experience would be a valuable asset to your team.

- I am eager to contribute to the success of your organization.

- I am confident that I can make a significant contribution to your company’s ongoing success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Treat Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Treat Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Heat Treat Supervisor is responsible for overseeing and managing all aspects of a heat treatment operation within a manufacturing facility. This role plays a vital part in ensuring that metal components meet the required specifications and quality standards. Key job responsibilities of a Heat Treat Supervisor include:

1. Production Management

Supervising and coordinating production schedules to ensure timely completion of heat treatment processes.

- Assigning tasks and responsibilities to heat treat operators.

- Monitoring production progress and implementing corrective actions to address bottlenecks or delays.

2. Quality Control

Ensuring that heat treatment processes adhere to established quality standards and specifications.

- Conducting inspections and testing to verify the quality of heat-treated components.

- Identifying and resolving any deviations from specifications and implementing corrective measures.

- Maintaining accurate records of heat treatment parameters and results.

3. Equipment Maintenance

Maintaining and calibrating heat treatment equipment to ensure optimal performance.

- Performing preventive maintenance tasks and repairs on heat treatment furnaces, quench tanks, and other equipment.

- Coordinating with maintenance personnel for major repairs or upgrades.

4. Process Development and Improvement

Continuously seeking ways to improve heat treatment processes and reduce costs.

- Evaluating new technologies and equipment to enhance efficiency.

- Collaborating with engineers and metallurgists to optimize heat treatment parameters.

- Implementing process improvements to reduce cycle times, energy consumption, and waste.

5. Safety and Environmental Compliance

Enforcing safety regulations and ensuring compliance with environmental standards.

- Conducting safety inspections and training employees on proper handling of heat treatment equipment.

- Monitoring emissions and implementing measures to minimize environmental impact.

- Adhering to all applicable safety and environmental regulations and guidelines.

Interview Tips

To ace an interview for the Heat Treat Supervisor position, it is essential to prepare thoroughly and showcase your relevant skills and experience.

1. Research the Company and the Role

Research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and the requirements of the position.

- Visit the company’s website and social media platforms.

- Read industry publications and articles about heat treatment.

- Network with professionals in the field to gain insights.

2. Highlight Your Relevant Skills and Experience

Emphasize your experience in heat treat operations, including production management, quality control, equipment maintenance, and process improvement.

- Use specific examples to demonstrate your abilities.

- Quantify your accomplishments whenever possible.

- Explain how your skills and experience align with the job requirements.

3. Showcase Your Leadership and Management Abilities

Heat Treat Supervisors are responsible for leading and managing a team. Highlight your leadership style, communication skills, and ability to motivate and empower your team.

- Describe situations where you successfully led or motivated a team to achieve goals.

- Explain how you handle conflicts and challenges within a team.

- Discuss your approaches to employee development and performance management.

4. Demonstrate Your Commitment to Safety and Quality

Heat treatment operations require a strong commitment to safety and quality. Demonstrate your understanding of safety regulations and standards, and your commitment to ensuring that products meet the highest quality standards.

- Describe your experience with implementing and enforcing safety procedures.

- Discuss your approaches to quality control and process improvement.

- Explain how you ensure that products meet customer specifications and industry standards.

5. Practice Your Answers and Seek Feedback

Practice answering common interview questions related to heat treatment, leadership, and management. Seek feedback from a mentor, career counselor, or friend to improve your responses.

- Prepare for questions about your technical skills, experience, and leadership abilities.

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result).

- Get feedback on your answers and make adjustments to improve clarity and impact.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Heat Treat Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.