Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Heat Treater Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

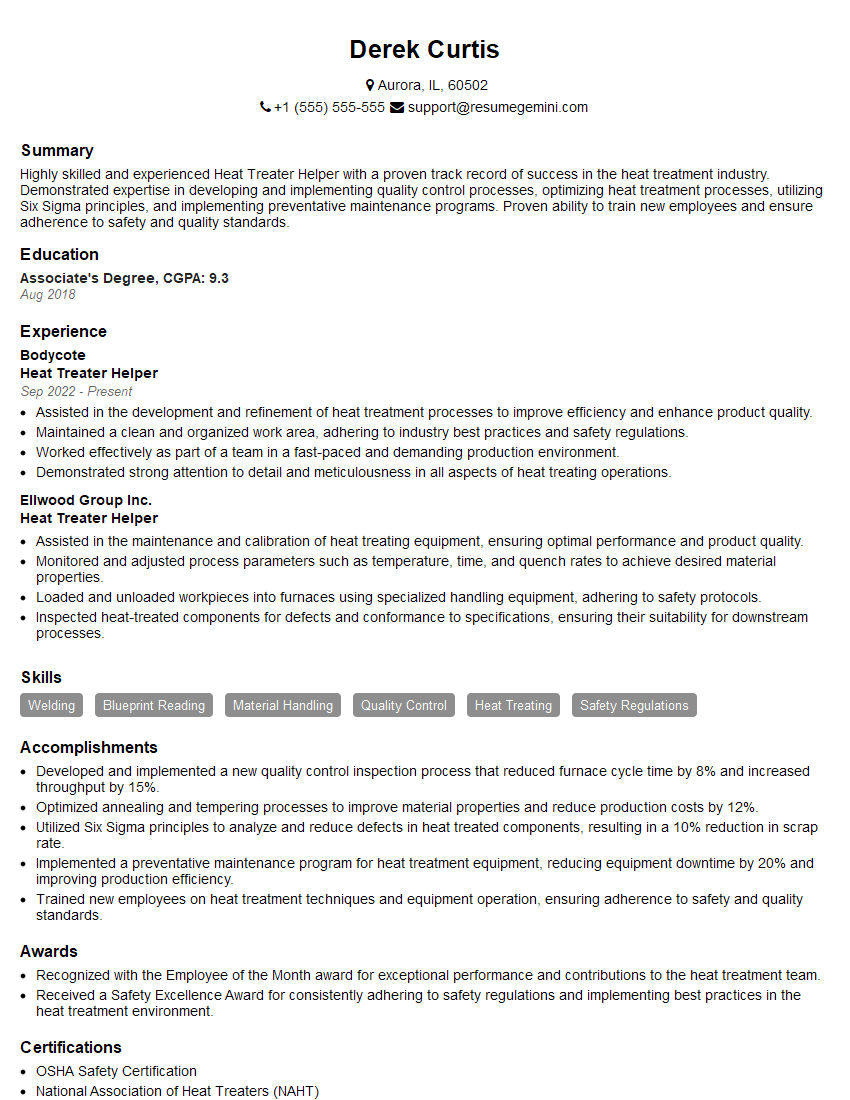

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Treater Helper

1. How do you ensure accurate temperature readings during the heat treatment process?

To ensure accurate temperature readings during the heat treatment process, I follow these steps:

- Calibrate temperature measuring devices regularly using certified standards.

- Place thermocouples or other temperature sensors in close contact with the workpiece to minimize heat transfer resistance.

- Monitor temperature readings continuously throughout the heat treatment cycle and adjust settings if necessary.

- Record temperature data accurately and maintain a log for traceability.

- Follow established protocols and procedures to prevent errors or deviations from specified temperature requirements.

2. Describe the importance of controlling quench rates during the heat treatment process.

Controlling quench rates during the heat treatment process is critical for several reasons:

Preventing distortion:

- Rapid quenching can cause uneven cooling, leading to internal stresses and potential distortion.

Achieving desired microstructure:

- Different quench rates result in different cooling rates, which influence the formation of specific microstructures.

- For example, rapid quenching promotes the formation of martensite, while slower quenching allows for precipitation reactions.

Ensuring mechanical properties:

- Quench rates can affect the mechanical properties of the treated material, such as hardness, toughness, and strength.

- By controlling quench rates, desired mechanical properties can be achieved.

3. Explain the purpose and benefits of tempering after quenching during heat treatment.

Tempering is a critical step after quenching during heat treatment, serving several purposes and providing various benefits:

- Stress relief: Tempering reduces internal stresses induced by quenching, improving the material’s toughness and preventing cracking.

- Hardness adjustment: Tempering at specific temperatures can soften the material to a desired hardness level, balancing strength and toughness.

- Microstructure stabilization: Tempering allows for the precipitation of carbides, stabilizing the microstructure and improving dimensional stability.

- Improved machinability: Tempering can make the material more machinable, reducing cutting forces and tool wear.

4. What factors should be considered when selecting a quenching medium for a specific heat treatment process?

When selecting a quenching medium for a specific heat treatment process, the following factors should be considered:

- Desired cooling rate: Different quenching media provide different cooling rates, which influence the resulting microstructure and mechanical properties.

- Heat capacity and conductivity: The heat capacity and conductivity of the quenching medium affect its ability to absorb and transfer heat from the workpiece.

- Vaporization temperature: A quenching medium with a high vaporization temperature is preferred to avoid boiling and the formation of vapor bubbles that can reduce cooling efficiency.

- Safety hazards: The potential hazards associated with the quenching medium, such as flammability, toxicity, or chemical reactivity, must be evaluated.

- Environmental considerations: The environmental impact of the quenching medium should be considered, including its disposal and recycling options.

5. Describe the different types of heat treatment furnaces and their applications.

There are various types of heat treatment furnaces, each with specific applications:

- Batch furnaces: Used for small to medium-sized workpieces, holding them at a specific temperature for a set duration.

- Continuous furnaces: Workpieces are continuously fed through the furnace, allowing for high production rates.

- Vacuum furnaces: Used for heat treating materials in a vacuum environment, reducing oxidation or decarburization.

- Atmosphere-controlled furnaces: Provide a specific atmosphere inside the furnace, such as inert gases or reducing gases, to control the surface properties of the treated materials.

- Induction furnaces: Utilize electromagnetic induction to generate heat within the workpiece, allowing for localized heating or selective hardening.

6. How do you handle and store heat-treated materials to prevent deterioration or damage?

To prevent deterioration or damage to heat-treated materials, I take the following precautions:

- Proper cooling: Cooling heat-treated materials slowly and evenly to avoid cracking or distortion.

- Storage in a controlled environment: Storing materials in a dry, temperature-controlled environment to prevent corrosion or oxidation.

- Use of protective coatings: Applying protective coatings, such as oils or lubricants, to prevent surface damage or contamination.

- Proper handling techniques: Using appropriate lifting equipment and avoiding impact or excessive force when handling heat-treated materials.

7. Describe the quality control measures used in a heat treatment facility.

In a heat treatment facility, the following quality control measures are typically implemented:

- Temperature monitoring: Regularly calibrating and monitoring temperature measuring devices to ensure accurate temperature readings.

- Material testing: Conducting hardness testing, tensile testing, and other mechanical tests to verify the properties of heat-treated materials.

- Metallurgical analysis: Examining the microstructure of heat-treated materials using techniques like optical microscopy to ensure proper heat treatment.

- Process documentation: Maintaining detailed records of heat treatment parameters, including temperature, time, and quenching medium, for traceability and quality control.

- Regular audits: Conducting internal and external audits to assess compliance with quality standards and identify areas for improvement.

8. What are the common problems encountered in heat treatment and how do you address them?

Some common problems encountered in heat treatment include:

- Distortion: Caused by improper temperature control or uneven cooling, can be addressed by stress relieving or re-heat treating.

- Cracking: Resulting from excessive hardness or rapid cooling, can be prevented by proper tempering and controlling quench rates.

- Oxidation or decarburization: Caused by exposure to air or improper atmosphere control, can be mitigated by using controlled atmospheres or protective coatings.

- Incomplete hardening: Occurs when the temperature or time is insufficient, can be rectified by re-heat treating at the correct parameters.

9. What is the importance of understanding heat treatment equipment and its maintenance?

Understanding heat treatment equipment and its maintenance is essential for:

- Ensuring safety: Proper maintenance prevents malfunctions, explosions, or other hazardous events.

- Optimizing performance: Regular maintenance ensures equipment operates efficiently, reducing downtime and maximizing productivity.

- Extending equipment life: Timely maintenance and repairs prolong the lifespan of heat treatment equipment.

- Maintaining quality: Well-maintained equipment helps achieve consistent and high-quality heat treatment results.

- Troubleshooting: Understanding equipment allows for quick identification and resolution of any operational issues.

10. Can you describe the role of heat treatment in the manufacturing process of a specific industry, such as automotive or aerospace?

In the automotive industry, heat treatment plays a vital role in enhancing the performance and durability of various components, such as:

- Engine components: Crankshafts, camshafts, and gears undergo heat treatment to increase strength, wear resistance, and fatigue life.

- Transmission components: Gears, shafts, and bearings are heat-treated to improve their load-bearing capacity and reduce friction.

- Suspension components: Springs and shock absorbers are heat-treated to achieve the desired stiffness and damping characteristics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Treater Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Treater Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Heat Treater Helper, you will assist in the heat treatment process of metal components to enhance their properties and meet desired specifications.

1. Material Preparation

Support the heat treatment process by preparing materials, inspecting incoming components, and ensuring proper handling.

- Inspect incoming materials for defects and compliance with specifications.

- Maintain proper storage conditions for materials to prevent contamination.

2. Heat Treatment Operations

Assist heat treaters in operating and maintaining furnaces, quenching systems, and other equipment used in the heat treatment process.

- Load and unload materials into furnaces according to specified temperature and time parameters.

- Monitor heating and cooling processes to ensure adherence to quality standards.

3. Post-Heat Treatment Handling

Assist in the post-heat treatment process, including tempering, quenching, and cleaning of treated components.

- Operate tempering ovens and quenching tanks to achieve desired material properties.

- Clean and inspect treated components to ensure quality and compliance with specifications.

4. Quality Control

Assist in maintaining quality control by conducting basic inspections, monitoring equipment performance, and reporting any deviations.

- Perform basic visual inspections and dimensional measurements to verify product quality.

- Monitor equipment performance and identify potential issues to prevent downtime.

Interview Tips

To ace your interview for a Heat Treater Helper position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This will enable you to ask informed questions and demonstrate your interest in the role.

2. Highlight Relevant Experience

Emphasize any prior experience or skills that are relevant to the job, such as material handling, equipment operation, or quality control. Quantify your accomplishments using specific examples to demonstrate your capabilities.

3. Review Technical Concepts

Review basic concepts of heat treatment, including heat transfer, quenching methods, and material properties. This will show the interviewer that you possess a fundamental understanding of the industry.

4. Practice Common Interview Questions

Prepare for common interview questions, such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses?” Practice delivering clear and concise answers.

5. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your enthusiasm and interest in the position. For example, you could inquire about the company’s growth plans or the opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Heat Treater Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.