Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Heat Treating Bluer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

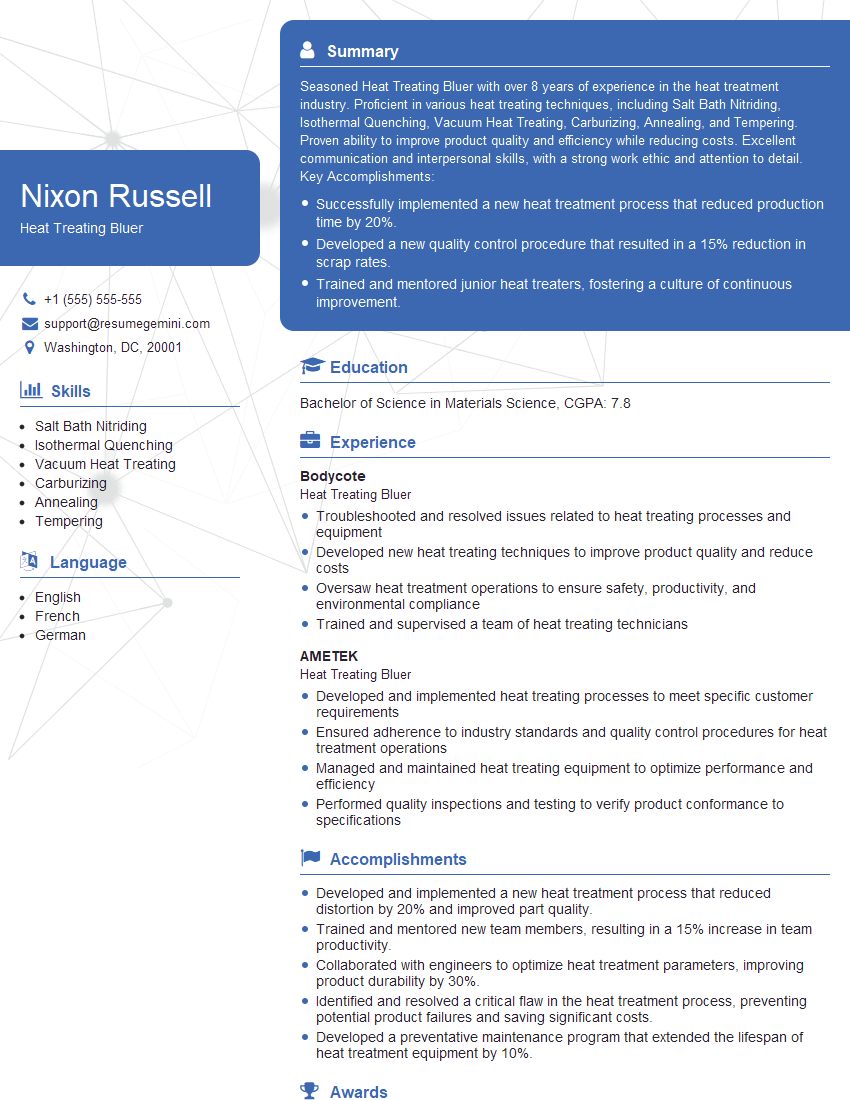

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Treating Bluer

1. What are the different types of heat treating processes used in the industry?

There are several types of heat treating processes used in the industry, including:

- Annealing: A process that involves heating a metal to a specific temperature and then cooling it slowly to improve its ductility and toughness.

- Normalizing: A process that involves heating a metal to a specific temperature and then cooling it in air to improve its strength and hardness.

- Hardening: A process that involves heating a metal to a specific temperature and then cooling it rapidly to increase its hardness and wear resistance.

- Tempering: A process that involves heating a hardened metal to a specific temperature and then cooling it slowly to reduce its hardness and improve its toughness.

2. What are the key factors to consider when selecting a heat treating process?

Factors to Consider

- Type of metal being treated: Different metals have different heat treating requirements.

- Desired properties: The desired properties of the metal will determine the heat treating process used.

- Equipment available: The type of heat treating equipment available will also influence the process selection.

- Cost: The cost of the heat treating process must be taken into account.

- Metallurgical considerations: The metallurgical considerations involve understanding the desired properties of the metal and the effect of heat treatment on these properties.

3. What are the common defects that can occur during heat treatment and how can they be prevented?

Common defects that can occur during heat treatment include:

- Warping: Warping can occur when the metal is not heated evenly or when it is cooled too quickly.

- Cracking: Cracking can occur when the metal is heated too quickly or when it is cooled too quickly.

- Scaling: Scaling can occur when the metal is heated in an oxidizing atmosphere.

- Decarburization: Decarburization can occur when the metal is heated in a reducing atmosphere.

These defects can be prevented by using proper heating and cooling techniques and by controlling the atmosphere in the furnace.

4. What are the different types of heat treating furnaces and what are their advantages and disadvantages?

Different types of heat treating furnaces include:

- Box furnaces: Box furnaces are used for general heat treating applications and are available in a variety of sizes.

- Pit furnaces: Pit furnaces are used for heat treating large parts and are available in a variety of depths.

- Rotary furnaces: Rotary furnaces are used for heat treating small parts and are available in a variety of sizes.

- Vacuum furnaces: Vacuum furnaces are used for heat treating in a vacuum environment and are available in a variety of sizes.

The advantages and disadvantages of each type of furnace vary depending on the specific application.

5. What are the safety precautions that must be taken when working with heat treating equipment?

Safety precautions that must be taken when working with heat treating equipment include:

- Wearing proper protective gear: This includes wearing gloves, safety glasses, and a lab coat.

- Operating equipment safely: This includes following all safety instructions and using the equipment only for its intended purpose.

- Maintaining equipment properly: This includes regular inspections and maintenance to ensure that the equipment is in good working order.

- Being aware of potential hazards: This includes being aware of the potential for burns, fires, and explosions.

6. What are the latest advancements in heat treating technology?

Some of the latest advancements in heat treating technology include:

- Laser heat treating: Laser heat treating is a process that uses a laser to heat a metal to a specific temperature. This process is often used for heat treating small parts or for localized heat treating.

- Induction heating: Induction heating is a process that uses an electromagnetic field to heat a metal to a specific temperature. This process is often used for heat treating large parts or for heat treating parts that are difficult to reach with other methods.

- Microwave heating: Microwave heating is a process that uses microwaves to heat a metal to a specific temperature. This process is often used for heat treating small parts or for heat treating parts that are difficult to reach with other methods.

7. What are the challenges facing the heat treating industry?

Some of the challenges facing the heat treating industry include:

- Increasing demand for heat treated parts: The demand for heat treated parts is increasing due to the growing use of metals in various industries.

- Rising costs of energy: The cost of energy is a significant factor in the cost of heat treating. As energy costs continue to rise, the cost of heat treating will also increase.

- Environmental regulations: Environmental regulations are becoming increasingly stringent, which is making it more difficult and expensive to operate a heat treating facility.

8. What are the career opportunities for heat treating bluers?

Career opportunities for heat treating bluers include:

- Heat treating technician: Heat treating technicians operate and maintain heat treating equipment and perform heat treating processes.

- Quality control inspector: Quality control inspectors ensure that heat treated parts meet the required specifications.

- Sales engineer: Sales engineers sell heat treating equipment and services to customers.

9. What are the personal qualities and skills that are important for a heat treating bluer?

Important personal qualities and skills for a heat treating bluer include:

- Attention to detail: Heat treating bluers must be able to pay close attention to detail in order to ensure that heat treating processes are performed correctly.

- Mechanical aptitude: Heat treating bluers must have mechanical aptitude in order to be able to operate and maintain heat treating equipment.

- Problem-solving skills: Heat treating bluers must be able to solve problems in order to ensure that heat treated parts meet the required specifications.

10. Why are you interested in working as a heat treating bluer?

I am interested in working as a heat treating bluer because I have always been fascinated by the metalworking industry. I find the process of heat treating metals to be very interesting and challenging, and I am eager to learn more about it. I am also confident that I have the necessary skills and qualities to be successful in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Treating Bluer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Treating Bluer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Heat Treating Bluer plays a crucial role in the metalworking industry, responsible for performing specialized techniques to enhance the properties and appearance of metal components.

1. Heat Treating Process

Thoroughly understanding and implementing heat treating processes, such as tempering, annealing, and hardening, to alter the mechanical properties of metals.

- Determining appropriate temperature ranges and cooling rates for specific metals to achieve desired outcomes.

- Monitoring and controlling heat treating equipment, including furnaces, heat baths, and quenchants, to ensure optimal conditions.

2. Plating and Finishing

Skilled in applying various electroplating techniques, such as bluing, to enhance surface protection and aesthetics.

- Preparing metal surfaces for plating by cleaning, degreasing, and activating to ensure proper adhesion.

- Maintaining and calibrating electroplating equipment to guarantee consistent results.

3. Quality Control

Ensuring the quality of heat-treated and plated components through rigorous inspections and testing.

- Inspecting parts for surface defects, dimensional accuracy, and adherence to specifications.

- Conducting hardness, tensile strength, and other mechanical tests to verify material properties.

4. Safety and Environmental Compliance

Maintaining a safe work environment and adhering to environmental regulations related to heat treating processes.

- Operating heat treating equipment safely and following established safety protocols.

- Properly handling and disposing of hazardous materials, including acids, bases, and solvents.

Interview Tips

Preparing thoroughly for your interview as a Heat Treating Bluer can significantly increase your chances of success.

1. Research the Company and Position

Gather information about the company’s background, industry, and the specific role you’re applying for. This knowledge will demonstrate your interest and help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read industry publications and news articles to stay up-to-date on current trends.

2. Highlight Your Skills and Experience

Showcase your expertise in heat treating processes, plating techniques, and quality control measures. Quantify your accomplishments whenever possible to provide tangible evidence of your abilities.

- Review the job description carefully and identify the key skills and responsibilities.

- Prepare specific examples from your previous work experience that demonstrate how you meet these requirements.

3. Practice Your Answers

Take time to prepare thoughtful and concise answers to common interview questions. Practice your delivery to ensure you can articulate your points clearly and professionally.

- Anticipate questions about your heat treating knowledge, quality control procedures, and safety practices.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

4. Prepare Questions for the Interviewer

Asking well-informed questions at the end of the interview shows your engagement and genuine interest in the position and the company. It also gives you an opportunity to gather additional information.

- Inquire about the company’s growth plans and industry outlook.

- Ask about opportunities for professional development and training.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Heat Treating Bluer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.