Feeling lost in a sea of interview questions? Landed that dream interview for Heat Treating Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Heat Treating Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

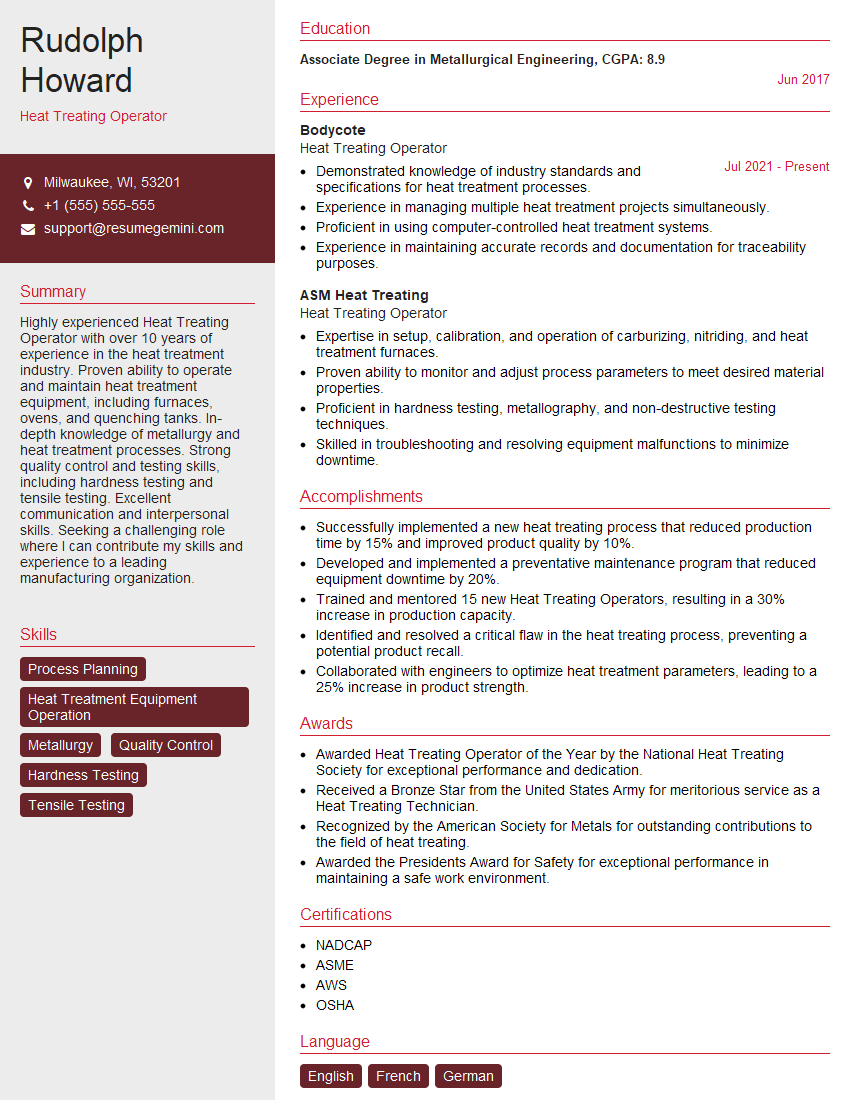

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heat Treating Operator

1. What are the different types of heat treating processes and their applications?

There are many types of heat treating processes, each with its own applications. Some of the most common types of heat treating processes include:

- Annealing: Annealing is a process that involves heating a metal to a high temperature and then slowly cooling it. This process makes the metal softer and more ductile.

- Hardening: Hardening is a process that involves heating a metal to a high temperature and then rapidly cooling it. This process makes the metal harder and more brittle.

- Tempering: Tempering is a process that involves heating a metal to a high temperature and then holding it at that temperature for a period of time before cooling it. This process makes the metal stronger and tougher.

- Stress relieving: Stress relieving is a process that involves heating a metal to a high temperature and then slowly cooling it. This process reduces the internal stresses in the metal, making it less likely to crack or warp.

2. What are the different types of heat treating equipment?

- Furnaces: Furnaces are used to heat metal to high temperatures. They can be powered by gas, electricity, or oil.

- Ovens: Ovens are used to heat metal to lower temperatures. They can be powered by gas, electricity, or oil.

- Induction heaters: Induction heaters use electromagnetic induction to heat metal. They are very efficient and can heat metal very quickly.

- Laser heaters: Laser heaters use lasers to heat metal. They are very precise and can heat metal to very high temperatures.

3. What are the safety precautions that must be followed when working with heat treating equipment?

- Always wear protective clothing, including gloves, safety glasses, and a lab coat.

- Never operate heat treating equipment unless you have been properly trained.

- Keep the work area clean and free of flammable materials.

- Be aware of the potential hazards of heat treating, such as burns, explosions, and toxic fumes.

4. What are the different types of materials that can be heat treated?

- Metals: Metals are the most common materials that are heat treated. Some of the most common metals that are heat treated include steel, aluminum, and copper.

- Plastics: Plastics can also be heat treated. Heat treating plastics can improve their strength, toughness, and durability.

- Glass: Glass can also be heat treated. Heat treating glass can make it stronger and more resistant to breakage.

5. What are the different factors that affect the heat treatment process?

- The type of material being heat treated

- The temperature of the heat treatment

- The length of time the material is heat treated

- The cooling rate of the material after heat treatment

6. What are the different types of defects that can occur during heat treatment?

- Cracking

- Warping

- Scaling

- Decarburization

7. How can defects be prevented during heat treatment?

- Using the correct heat treating process for the material

- Using the correct temperature and time for the heat treating process

- Using the correct cooling rate for the material

- Properly preparing the material for heat treatment

- Properly maintaining the heat treating equipment

8. What are the different types of testing that can be performed on heat treated materials?

- Hardness testing

- Tensile testing

- Impact testing

- Fatigue testing

- Corrosion testing

9. What are the different types of careers that are available in the heat treating industry?

- Heat treating operator

- Heat treating engineer

- Heat treating metallurgist

- Heat treating sales representative

- Heat treating quality control inspector

10. What are the different types of training that are available for heat treating operators?

- On-the-job training

- Classroom training

- Online training

- Seminars

- Workshops

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heat Treating Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heat Treating Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heat Treating Operators play a critical role in the manufacturing process, ensuring the precise and efficient heat treatment of metal components to meet specific engineering requirements. Here are some of their key responsibilities:

1. Equipment Operation and Maintenance

Operate and monitor heat-treating equipment, including furnaces, ovens, and quenching tanks, to achieve desired material properties.

- Maintain and calibrate equipment regularly to ensure accuracy and safety.

- Monitor temperature and other process parameters to optimize heat treatment outcomes.

2. Material Handling and Preparation

Prepare metal parts or components for heat treatment, including cleaning, masking, and fixturing.

- Review engineering drawings and specifications to understand part requirements.

- Unload and load heat-treated parts from equipment, ensuring proper handling and quality control.

3. Quality Control and Inspection

Perform quality checks and inspections on heat-treated parts using measuring tools and testing equipment.

- Verify part dimensions, hardness, and other quality characteristics to ensure compliance.

- Report any deviations or defects to supervisors and take corrective actions.

4. Process Optimization

Collaborate with engineers and technicians to improve heat-treating processes and reduce production time.

- Suggest process modifications or equipment upgrades to enhance efficiency.

- Document and maintain process data for future reference and optimization.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to help you ace your Heat Treating Operator interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products. Research the specific job requirements and responsibilities to demonstrate your understanding of the role.

- Visit the company website and LinkedIn page for company information.

- Review the job description thoroughly to identify key responsibilities and qualifications.

2. Highlight Your Skills and Experience

Tailor your resume and interview answers to emphasize the skills and experience that are relevant to the position. Quantify your accomplishments and provide specific examples.

- Showcase your expertise in heat-treating equipment operation, process optimization, and quality control.

- Provide examples of projects where you successfully improved efficiency or reduced production time.

3. Prepare for Technical Questions

Expect technical questions about heat-treating processes, equipment, and materials. Be prepared to discuss your understanding of different heat-treatment techniques and their applications.

- Review heat-treating principles, including annealing, tempering, and hardening.

- Be familiar with different types of heat-treating equipment, such as batch furnaces and continuous ovens.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare questions about the company’s growth plans, safety protocols, or opportunities for professional development.

- Ask about the company’s commitment to quality and customer satisfaction.

- Inquire about the training and advancement opportunities available for Heat Treating Operators.

5. Dress Professionally and Be Punctual

First impressions matter, so dress professionally and arrive for your interview on time. Maintain an enthusiastic and positive attitude throughout the interview process.

- Wear business casual attire, such as a button-down shirt, slacks, and closed-toe shoes.

- Arrive 10-15 minutes early to allow time for check-in and preparation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Heat Treating Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.