Feeling lost in a sea of interview questions? Landed that dream interview for Heavy Equipment Plumbing Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Heavy Equipment Plumbing Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

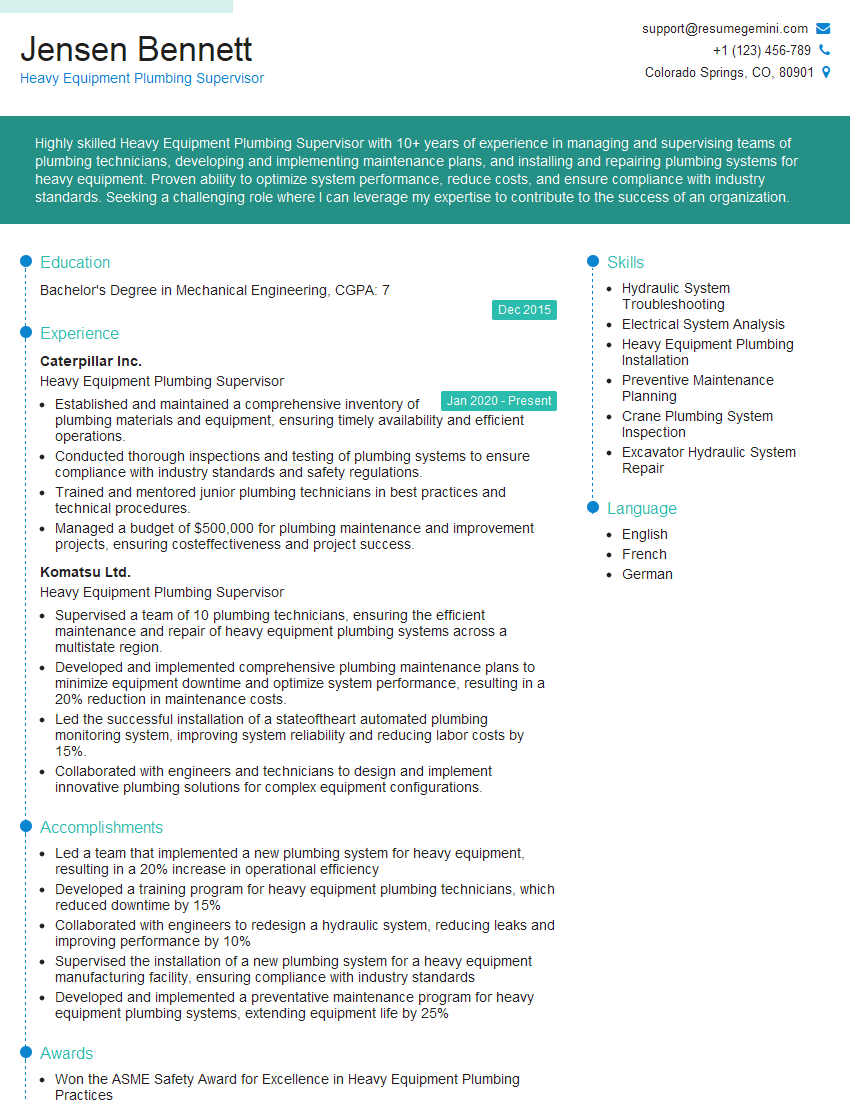

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heavy Equipment Plumbing Supervisor

1. Describe the key responsibilities of a Heavy Equipment Plumbing Supervisor.

- Overseeing and coordinating the maintenance and repair of plumbing systems on heavy equipment.

- Diagnosing and resolving plumbing problems effectively and efficiently.

- Ensuring compliance with safety regulations and industry standards.

- Training and supervising a team of plumbing technicians.

- Managing budgets and resources related to plumbing operations.

2. Explain the different types of plumbing systems found in heavy equipment.

Water Systems:

- Fresh water systems for drinking and washing.

- Grey water systems for drainage.

Hydraulic Systems:

- Open-circuit systems with reservoirs and pumps.

- Closed-circuit systems with accumulators and pressurized fluid.

Fuel Systems:

- Diesel fuel systems for engines.

- Gasoline fuel systems for generators.

Cooling Systems:

- Closed-loop systems with coolant, radiators, and fans.

- Open-loop systems with raw water for cooling.

3. How do you approach diagnosing and resolving complex plumbing problems on heavy equipment?

- Gather information about the problem, including symptoms and operating conditions.

- Conduct a thorough visual inspection and testing to identify potential causes.

- Consult technical manuals and work with equipment manufacturers for guidance.

- Use specialized tools and equipment for diagnostics, such as pressure gauges and flow meters.

- Apply troubleshooting principles and logical reasoning to determine the root cause.

4. Describe your experience with managing a team of plumbing technicians.

Team Management:

- Assigning tasks, setting performance goals, and providing feedback.

- Conducting training and development sessions to enhance skills.

- Promoting teamwork, collaboration, and a positive work environment.

- Handling performance issues and providing support when necessary.

Safety and Compliance:

- Enforcing safety protocols and ensuring compliance with industry standards.

- Conducting regular safety inspections and addressing any hazards.

- Providing training on proper handling of hazardous materials and equipment.

5. What are the key safety regulations and industry standards related to plumbing in heavy equipment?

- Occupational Safety and Health Administration (OSHA): Regulations on safety procedures, hazardous materials handling, and personal protective equipment (PPE).

- American Society of Mechanical Engineers (ASME): Standards for plumbing systems, including pipe materials, fittings, and pressure testing.

- National Fire Protection Association (NFPA): Codes for fire protection systems, including water supply and drainage.

- Environmental Protection Agency (EPA): Regulations on water quality, wastewater discharge, and hazardous waste disposal.

6. How do you stay up-to-date on the latest technologies and advancements in heavy equipment plumbing?

- Attending industry conferences and workshops.

- Reading technical journals and trade publications.

- Consulting with equipment manufacturers and industry experts.

- Participating in online forums and discussion groups.

- Obtaining certifications or specialized training in relevant areas.

7. Describe your experience with managing budgets and resources for plumbing operations.

- Developing and implementing annual budgets for plumbing maintenance and repairs.

- Tracking expenses and identifying opportunities for cost savings.

- Negotiating with vendors and suppliers to secure favorable terms.

- Ensuring efficient use of materials, equipment, and labor.

- Preparing reports and presentations on budget performance and resource allocation.

8. What software and tools are you proficient in using for plumbing design, analysis, and maintenance?

- Computer-aided design (CAD) software: AutoCAD, SolidWorks.

- Hydraulic simulation software: FluidSIM, AMESim.

- Diagnostic and testing equipment: Pressure gauges, flow meters, leak detectors.

- Enterprise resource planning (ERP) systems: SAP, Oracle.

9. How do you ensure that plumbing systems on heavy equipment are operating at optimal efficiency?

- Conducting regular inspections and maintenance checks.

- Monitoring system performance through sensors and data analysis.

- Implementing preventive maintenance programs to address potential issues.

- Optimizing system design and component selection for efficiency.

- Training operators on proper equipment use and maintenance practices.

10. Describe a situation where you faced a challenging plumbing issue on heavy equipment and how you resolved it.

Situation: Describe the specific plumbing problem encountered.

Analysis: Explain how you diagnosed the issue, considering various factors.

Solution: Describe the steps taken to resolve the problem, including the specific techniques and tools used.

Outcome: Explain the successful resolution of the issue and the impact on equipment performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heavy Equipment Plumbing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heavy Equipment Plumbing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Heavy Equipment Plumbing Supervisor, you will oversee the installation, maintenance, and repair of plumbing systems in heavy equipment within a mine or construction site.

1. Planning and Coordination

You will develop and implement plumbing plans, allocate resources, and coordinate with other departments to ensure timely and efficient completion of projects.

- Plan, schedule, and coordinate plumbing installation, maintenance, and repair activities

- Allocate resources, including personnel, equipment, and materials, to complete projects

- Collaborate with other departments, such as engineering, operations, and maintenance, to ensure project integration

2. Supervision and Training

You will lead a team of plumbers, providing guidance, training, and performance evaluation.

- Supervise and direct a team of plumbers, providing technical guidance and support

- Train and develop plumbers, ensuring they have the skills and knowledge to perform their jobs effectively

- Evaluate plumber performance, providing feedback and guidance for improvement

3. Quality Control and Safety

You will ensure that all plumbing work meets quality standards and complies with safety regulations.

- Implement quality control measures to ensure plumbing systems meet specifications and industry standards

- Enforce safety regulations and protocols to prevent accidents and injuries

- Conduct inspections and audits to assess compliance with quality and safety standards

4. Troubleshooting and Problem-Solving

You will quickly identify and resolve plumbing problems, minimizing downtime and ensuring optimal equipment performance.

- Identify and diagnose plumbing problems, using technical expertise and troubleshooting skills

- Develop and implement solutions to resolve plumbing issues, ensuring timely and efficient repairs

- Monitor plumbing systems and identify potential problems before they occur, implementing preventive maintenance measures

Interview Tips

To ace your interview for the Heavy Equipment Plumbing Supervisor position, consider the following tips:

1. Research the Company and Industry

Show the interviewer that you have taken the time to learn about the company and the mining or construction industry. This will demonstrate your interest in the position and your understanding of the field.

- Visit the company’s website to learn about its history, mission, and values.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies.

- Connect with professionals in the industry on LinkedIn to gain insights into the company and the role.

2. Highlight Your Technical Expertise

The interviewer will be interested in your technical skills and knowledge of plumbing systems in heavy equipment. Be prepared to discuss your experience in the following areas:

- Plumbing system design, installation, and maintenance

- Heavy equipment hydraulic systems

- Troubleshooting and repair of plumbing problems

- Quality control and safety procedures

3. Emphasize Your Leadership and Management Skills

As a supervisor, you will be responsible for leading a team of plumbers. Highlight your leadership, management, and communication skills during the interview.

- Describe your experience in motivating, training, and evaluating team members.

- Explain how you build strong relationships with team members and create a positive work environment.

- Share examples of how you have successfully resolved conflicts and managed challenging team situations.

4. Prepare for Common Interview Questions

Be prepared to answer common interview questions related to your technical skills, leadership abilities, and experience in the industry.

- Tell me about your experience in supervising a team of plumbers.

- Describe a time when you had to troubleshoot and resolve a complex plumbing problem.

- How do you stay up-to-date on the latest plumbing technologies and best practices?

5. Practice Your Answers

Practice your answers to common interview questions out loud. This will help you feel more confident and articulate during the actual interview.

- Ask a friend or family member to conduct a mock interview with you.

- Record yourself answering interview questions and watch the playback to identify areas for improvement.

- Use online resources or interview preparation books to practice answering common interview questions.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Heavy Equipment Plumbing Supervisor role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.