Are you gearing up for an interview for a Heavy Lift Rigger position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Heavy Lift Rigger and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

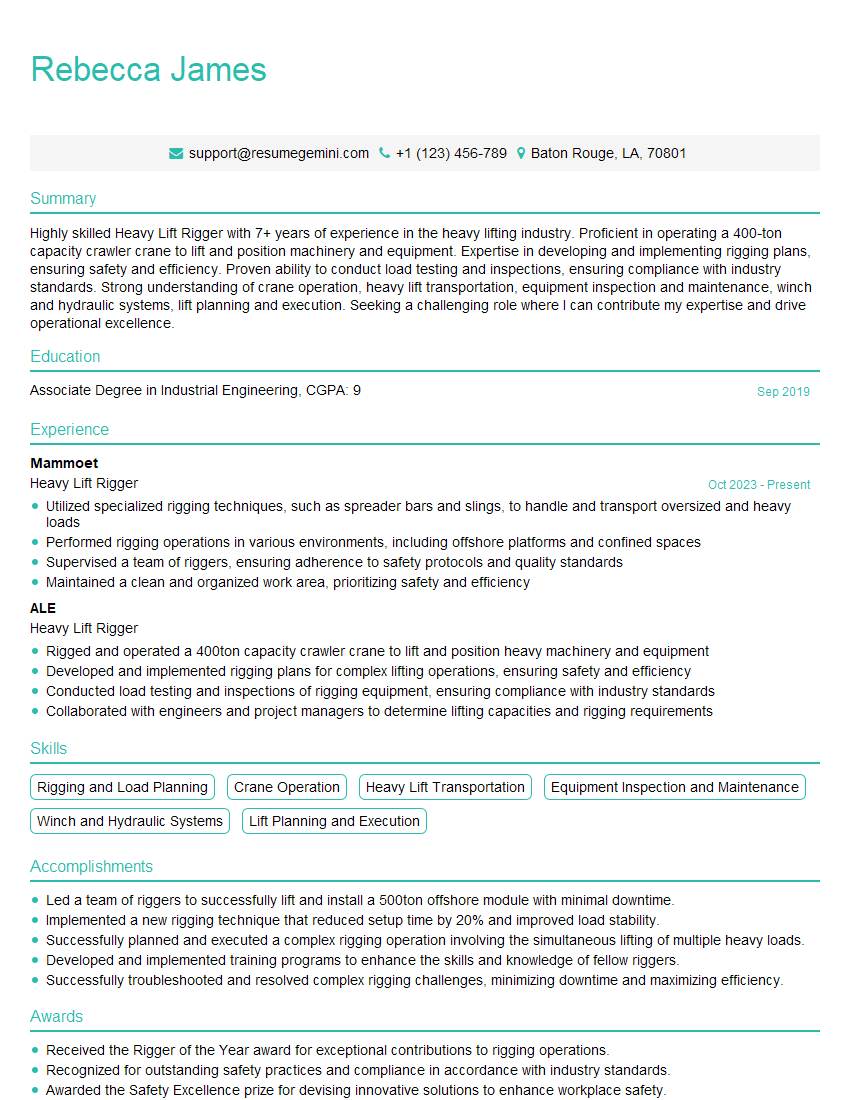

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heavy Lift Rigger

1. What are the different types of heavy lift rigging equipment?

There are various types of heavy lift rigging equipment, but the most common ones include:

- Cranes: Mobile, crawler, and tower cranes are used to lift and move heavy objects vertically or horizontally.

- Forklifts: These are used to lift and transport heavy objects over short distances.

- Gantry cranes: These are used to lift and move heavy objects within a specific area, such as a factory or warehouse.

- Hoists: These are used to lift and lower heavy objects vertically.

- Slings: These are used to attach heavy objects to lifting equipment.

2. What are the safety precautions that must be taken when working with heavy lift rigging equipment?

- Always follow the manufacturer’s instructions for the equipment you are using.

- Inspect the equipment before each use to ensure it is in good working condition.

- Only use the equipment for its intended purpose.

- Never overload the equipment.

- Be aware of your surroundings and potential hazards.

- Wear appropriate personal protective equipment, such as hard hats, safety glasses, and gloves.

- Never work alone when lifting heavy objects.

- Always have a spotter to guide the load and watch for hazards.

- Communicate clearly with your crew members.

- Be aware of the weight and size of the load you are lifting.

3. How do you calculate the weight of a heavy object?

There are a few different ways to calculate the weight of a heavy object. One way is to use a weight scale. Another way is to use the formula: Weight = Mass x Gravity. The mass of an object is measured in kilograms (kg), and the gravity of the Earth is 9.8 m/s². So, for example, if you have an object that has a mass of 100 kg, its weight would be 100 kg x 9.8 m/s² = 980 N.

4. What are the different types of slings used in heavy lift rigging?

- Wire rope slings

- Chain slings

- Synthetic slings

- Natural fiber slings

Each type of sling has its own advantages and disadvantages, so it is important to choose the right sling for the job.

5. How do you determine the safe working load of a sling?

The safe working load of a sling is determined by a number of factors, including the material of the sling, the size of the sling, and the condition of the sling. It is important to consult the manufacturer’s specifications for the specific sling you are using.

6. What are the different types of hitches used in heavy lift rigging?

- Basket hitch

- Choker hitch

- Vertical hitch

- Horizontal hitch

The type of hitch used will depend on the shape of the load and the lifting equipment being used.

7. How do you inspect a heavy lift rigging sling?

- Look for any cuts, tears, or abrasions in the material.

- Check the hardware for any damage or wear.

- Inspect the stitching for any loose or broken threads.

- Make sure the sling is properly labeled with its safe working load.

8. What are the different types of rigging hardware?

- Shackles

- Clevises

- Turnbuckles

- Hooks

- Eye bolts

Rigging hardware is used to connect different components of a rigging system.

9. How do you calculate the center of gravity of a heavy object?

The center of gravity of an object is the point at which the weight of the object is evenly distributed. To calculate the center of gravity, you need to find the midpoint of the object in all three dimensions.

10. What are the different types of heavy lift rigging systems?

- Single-point rigging

- Multi-point rigging

- Overhead rigging

- Below-the-hook rigging

The type of rigging system used will depend on the weight and size of the load, the lifting equipment being used, and the work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heavy Lift Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heavy Lift Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Heavy Lift Riggers play a crucial role in construction, energy, and various industries, ensuring the safe and efficient lifting and moving of heavy objects. Their key responsibilities include:

1. Planning and Preparation

Riggers conduct thorough job planning and rigging site inspections, assessing the weight, dimensions, and rigging points of the objects to be lifted. They determine the proper equipment, rigging components, and safety measures necessary for each lift.

2. Equipment Operation

Operators safely and skillfully use various rigging equipment, such as cranes, hoists, winches, and shackles. They follow established procedures and industry standards to ensure all equipment is operated in a safe and controlled manner.

3. Signal Communication

Riggers are responsible for clear and effective signal communication during lifting operations. They use hand signals, radio, or other communication methods to convey instructions to crane operators and other crew members, coordinating the lift safely and efficiently.

4. Inspection and Maintenance

Riggers inspect rigging equipment, slings, chains, and other components regularly to ensure they are in safe working order. They conduct tests and repairs as needed, ensuring all equipment meets safety standards and is properly maintained.

Interview Tips

To ace an interview for a Heavy Lift Rigger position, candidates should prepare by:

1. Researching the Company and Industry

Learn about the company’s history, culture, and specific industry requirements. This shows your interest and understanding of the role and the company’s objectives.

2. Practicing Rigging Scenarios

Be prepared to discuss real-world rigging scenarios and demonstrate your knowledge of safe lifting procedures. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers. For example:

3. Highlighting Safety First Approach

Safety is paramount in rigging operations. Show that you prioritize safety by emphasizing your understanding of industry regulations, best practices, and your commitment to hazard identification and prevention.

4. Demonstrating Teamwork and Communication Skills

Rigging often involves collaboration with other team members. Showcase your ability to work effectively as part of a crew, communicate clearly, and coordinate with crane operators and other personnel.

Next Step:

Now that you’re armed with the knowledge of Heavy Lift Rigger interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Heavy Lift Rigger positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini