Are you gearing up for an interview for a Heavy Media Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Heavy Media Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

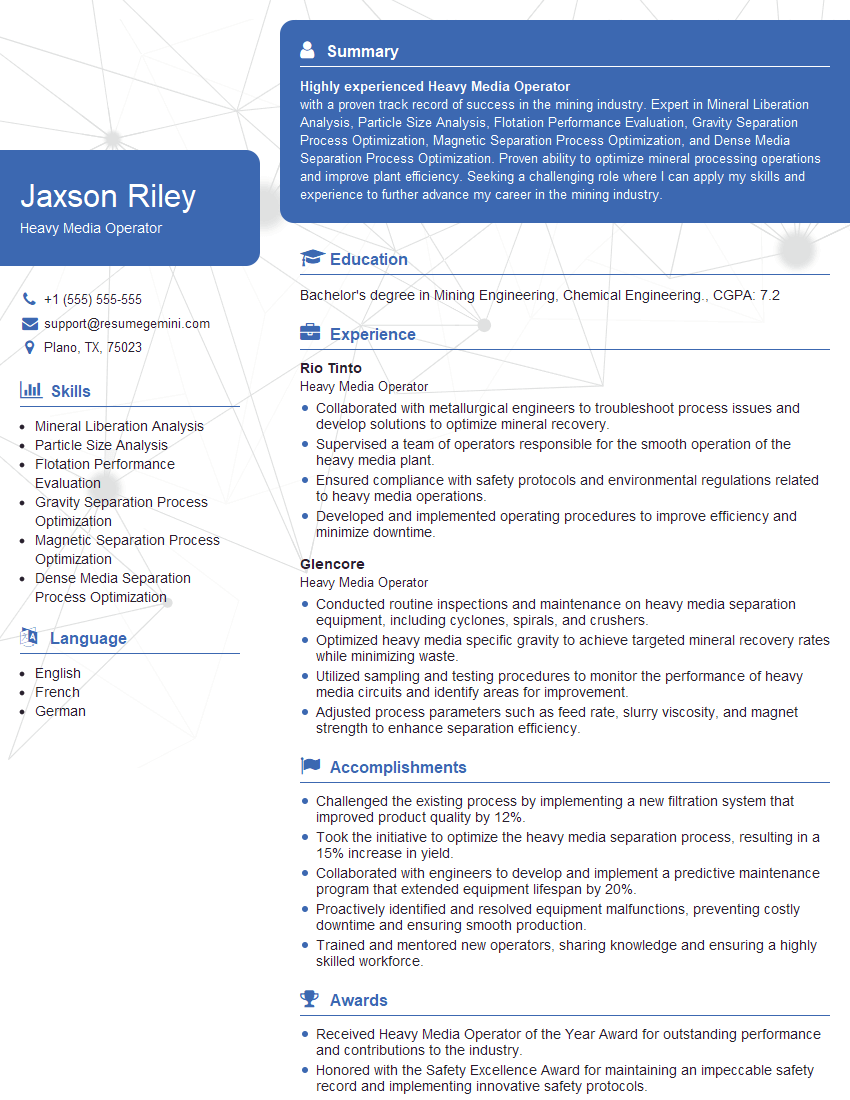

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heavy Media Operator

1. What is the purpose of a heavy media separator in mining operations?

The purpose of a heavy media separator (HMS) in mining operations is to separate minerals from waste materials based on their specific gravities. The HMS achieves this by creating a dense liquid medium that allows valuable minerals to sink while waste materials float to the surface.

2. Describe the key components of a heavy media separator and their functions.

Trommel Screen

- Removes large rocks and debris from the feed material.

- Prepares feed material for further processing.

Dense Medium Vessel

- Contains the suspension of heavy medium and feed material.

- Provides the medium for mineral separation based on density.

Cyclone

- Separates heavy minerals that sink from lighter waste materials that float.

- Uses centrifugal force to enhance separation efficiency.

Demagnetization Unit (Optional)

- Removes magnetic minerals from the feed material.

- Improves the separation efficiency of non-magnetic minerals.

3. What are the different types of heavy media used in HMS operations, and how are they selected?

- Magnetite: Finely ground iron ore, suitable for separating minerals with high magnetic susceptibility.

- Ferrosilicon: Alloy of iron and silicon, used for separating minerals with medium to low magnetic susceptibility.

- Dense Tetra Media (DTM): Synthetic organic liquid, used for separating minerals with low magnetic susceptibility and specific gravities close to the mineral of interest.

The selection of heavy media depends on the specific minerals being separated, their magnetic properties, and the desired separation efficiency.

4. What are the key parameters that need to be controlled during HMS operation to ensure optimal performance?

- Specific Gravity of the Medium: Ensures the desired separation of minerals based on their densities.

- Viscosity of the Medium: Affects the flowability and separation efficiency of the medium.

- Feed Rate: Controls the volume of material being processed, impacting the separation efficiency.

- Cyclone Pressure: Optimizes the separation efficiency of the cyclone by controlling the centrifugal force.

5. Describe the maintenance procedures for a heavy media separator to ensure optimal operation.

- Regular Cleaning: Prevent buildup and maintain cleanliness of all components, especially the cyclone.

- Inspection and Calibration: Check and calibrate sensors, instruments, and mechanical parts regularly.

- Lubrication: Ensure proper lubrication of moving parts, such as bearings and gears.

- Heavy Media Maintenance: Monitor and maintain the specific gravity and viscosity of the heavy media.

6. How do you troubleshoot common problems encountered in HMS operations?

- Poor Separation Efficiency: Check specific gravity, viscosity, feed rate, and cyclone pressure.

- Blockages or Clogging: Inspect trommel screen, dense medium vessel, and cyclone for obstructions.

- Mechanical Failures: Check bearings, gears, and other moving parts for malfunctions.

- Heavy Media Contamination: Monitor and replace heavy media as needed to maintain its properties.

7. Describe the safety precautions that must be taken when operating a heavy media separator.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures before performing maintenance.

- Be aware of potential hazards such as moving machinery and heavy media spills.

- Receive proper training and authorization before operating the equipment.

8. What is the role of automation in modern heavy media separation processes?

- Automated Process Control: Monitors and adjusts process parameters, such as specific gravity and feed rate.

- Data Acquisition and Analysis: Collects and analyzes data to optimize separation efficiency and identify potential issues.

- Remote Monitoring: Allows operators to monitor and control the process remotely, reducing downtime.

- Improved Safety: Reduces the need for manual intervention, minimizing risk to operators.

9. How do you stay up-to-date with the latest advancements in heavy media separation technology?

- Attend industry conferences and exhibitions.

- Read technical journals and articles.

- Participate in online forums and discussions.

- Consult with equipment manufacturers and industry experts.

10. How do you ensure that the heavy media separation process is environmentally sustainable?

- Waste Minimization: Optimize separation efficiency to reduce the amount of waste generated.

- Heavy Media Recovery: Implement systems to recover and reuse heavy media, reducing environmental impact.

- Water Conservation: Use water-efficient technologies and minimize water consumption in the process.

- Compliance with Regulations: Adhere to environmental regulations and standards to protect the environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heavy Media Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heavy Media Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Heavy Media Operator, your responsibilities involve operating heavy machinery, monitoring equipment, and ensuring smooth production processes in mining, processing, or waste management facilities.

1. Machinery Operation

Operate heavy machinery, such as crushers, screens, conveyors, and heavy equipment used in mining or recycling processes.

2. Quality Control

Monitor and control the quality of materials throughout the processing stages. Ensure compliance with specifications and maintain product quality.

3. System Maintenance

Perform routine inspections, maintenance, and repairs of machinery and equipment. Diagnose and troubleshoot system malfunctions.

4. Health and Safety

Adhere to health and safety regulations. Wear appropriate safety gear, follow safety protocols, and maintain a clean and organized work environment.

5. Collaboration

Coordinate with team members, supervisors, and other departments to ensure efficient operations and a safe work environment.

Interview Tips

To prepare for your Heavy Media Operator interview, consider the following tips:

1. Research the Company and Position

Demonstrate your interest in the company by researching their operations, industry trends, and specific requirements for the Heavy Media Operator role.

Example: “I understand that your company is a leader in the mining industry, and I am particularly interested in your commitment to sustainability and environmental protection.”

2. Highlight Relevant Experience

Emphasize your hands-on experience operating heavy machinery, including any experience in mining, processing, or waste management.

Example: “In my previous role, I operated a heavy-duty crusher for over three years, ensuring efficient material processing and maintaining high product quality.”

3. Show Proficiency in Maintenance

Highlight your skills in performing routine maintenance and repairs on heavy machinery. Explain how you diagnose and troubleshoot system malfunctions.

Example: “I am proficient in troubleshooting hydraulic systems and electrical circuits, ensuring quick and efficient repairs to minimize production downtime.”

4. Emphasize Safety and Compliance

Demonstrate your understanding and commitment to health and safety regulations. Explain your experience in following safety protocols and maintaining a safe work environment.

Example: “I have consistently maintained a clean and organized work area, and I am always vigilant in wearing appropriate safety gear, including a hard hat, safety glasses, and high-visibility clothing.”

5. Prepare Questions for the Interviewer

Show your engagement and interest by preparing thoughtful questions about the company, the role, and the industry.

Example: “What are the key performance indicators for this role?” or “What are the company’s goals for sustainability and innovation in the coming years?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Heavy Media Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!