Are you gearing up for an interview for a Heavy Threader position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Heavy Threader and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

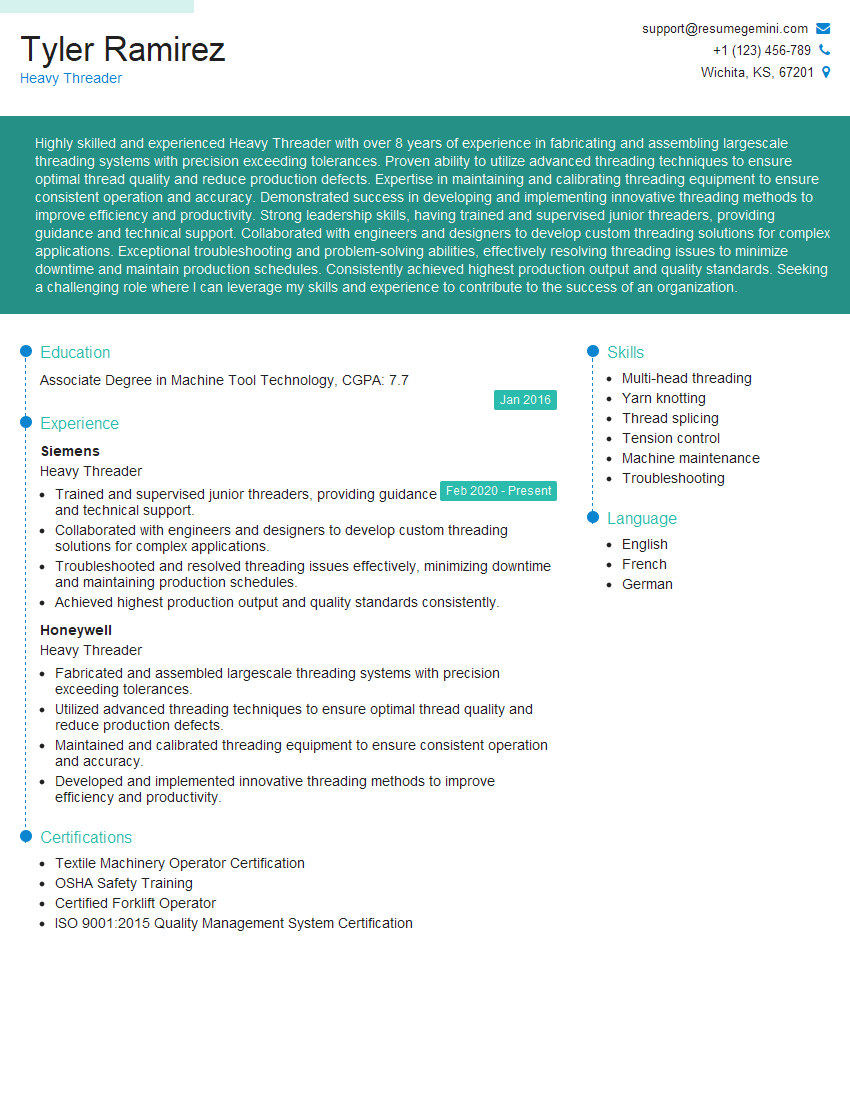

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heavy Threader

1. Describe the process of heavy threading with a conventional sewing machine?

The process of heavy threading with a conventional sewing machine involves several steps:

- Prepare the machine: Ensure that the machine is properly assembled and lubricated. Install a heavy-duty needle and thread that is suitable for the fabric being sewn.

- Wind the bobbin: Wind the heavy-duty thread onto the bobbin using the bobbin winder.

- Thread the upper thread: Pass the end of the thread through the tension discs and the needle threader to guide it through the needle.

- Thread the bobbin thread: Pull the thread from the bobbin and pass it through the bobbin case and up through the needle plate.

- Adjust the tension: Set the thread tension dials to the desired level to ensure proper stitching.

2. What are the different types of heavy-duty thread used in industrial sewing?

Natural Fibers

- Cotton: Strong and durable, but can be prone to stretching and shrinkage.

- Linen: Even stronger than cotton, but less elastic and more expensive.

Synthetic Fibers

- Nylon: Highly durable, elastic, and resistant to abrasion and chemicals.

- Polyester: Strong, colorfast, and resistant to sunlight and moisture.

- Kevlar: Exceptionally strong and heat-resistant, used in protective clothing and equipment.

3. How do you determine the correct needle size for heavy-duty sewing?

The correct needle size for heavy-duty sewing depends on the fabric thickness and thread weight:

- Thin fabrics: Use a smaller needle (e.g., size 14-16) with a sharp point to minimize damage to the fabric.

- Medium fabrics: Use a medium-sized needle (e.g., size 18-20) with a regular point for general-purpose sewing.

- Thick fabrics: Use a larger needle (e.g., size 22-24) with a blunt point to penetrate heavy layers of fabric.

4. What are the common problems encountered in heavy-duty sewing and how do you troubleshoot them?

- Thread breakage: Check for damaged or worn needles, excessive thread tension, or improper threading.

- Skipped stitches: Adjust the needle tension, check for burrs or nicks on the needle, and ensure the bobbin thread is properly tensioned.

- Puckering: Use a smaller needle size, reduce the stitch length, or tighten the thread tension.

- Fabric damage: Use the appropriate needle size and thread weight for the fabric, and adjust the tension settings accordingly.

5. What is the importance of proper maintenance for heavy-duty sewing machines?

Proper maintenance is crucial for the longevity and performance of heavy-duty sewing machines:

- Regular cleaning: Remove dust and lint from the machine using a soft brush and compressed air.

- Lubrication: Oil moving parts according to the manufacturer’s instructions to reduce friction and wear.

- Needle replacement: Replace needles regularly to ensure sharp points and prevent thread breakage.

- Tension adjustment: Check and adjust thread tension settings as needed to ensure proper stitch formation.

6. What are the safety precautions that should be observed when operating a heavy-duty sewing machine?

- Wear appropriate clothing: Avoid loose clothing that can get caught in the machine.

- Secure loose hair: Tie long hair back or wear a hairnet to prevent entanglement.

- Use safety glasses: Protect your eyes from flying debris.

- Keep hands away from the needle: Use a presser foot and guide the fabric with your fingers instead of your hands.

- Unplug the machine: Before performing maintenance or repairs, always unplug the machine from the power source.

7. Describe the different types of seams used in heavy-duty sewing?

- Plain seam: A basic seam used to join two pieces of fabric together.

- French seam: A double-stitched seam that encloses the raw edges for a clean and durable finish.

- Flat-felled seam: A strong and durable seam that is often used for heavy-duty applications like backpacks and tents.

- Bound seam: A seam where the raw edges are enclosed by a strip of fabric for a professional-looking finish.

8. What is the difference between a lock stitch and a chain stitch in heavy-duty sewing?

- Lock stitch: Creates a strong and secure stitch by interlocking the upper and lower threads, forming a criss-cross pattern.

- Chain stitch: Forms a continuous loop of thread rather than interlocking stitches, creating a stretchy and flexible seam.

9. How do you set up a heavy-duty sewing machine for top stitching?

To set up a heavy-duty sewing machine for top stitching:

- Use a heavy-duty needle and thread: Choose a needle size and thread weight appropriate for the fabric and stitching application.

- Adjust the stitch length: Set the stitch length to a shorter setting (e.g., 2-3 mm) to create a dense and durable stitch.

- Increase the presser foot pressure: Apply more pressure to the presser foot to ensure the fabric is held securely during stitching.

- Use a topstitching foot: Attach a topstitching foot to the machine to guide the stitching along the edge of the fabric.

10. What are the applications of heavy-duty sewing machines in various industries?

- Automotive: Manufacturing seat covers, upholstery, and safety belts.

- Marine: Creating sails, boat covers, and upholstery.

- Outdoor gear: Sewing tents, backpacks, and sleeping bags.

- Industrial: Producing conveyor belts, tarpaulins, and protective clothing.

- Clothing: Stitching heavy-duty garments such as workwear, jeans, and leather jackets.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heavy Threader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heavy Threader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Heavy Threader, you will be responsible for a wide range of tasks pertaining to the threading process. Your duties will include:

1. Threading Equipment Setup and Operation

intro paragraph

- Set up and prepare threading machinery, ensuring proper alignment and tension.

- Manage and monitor threading operations, making necessary adjustments to maintain production.

2. Quality Control and Inspection

intro paragraph

- Inspect thread quality and dimensions, ensuring adherence to specifications.

- Identify and resolve any defects or inconsistencies in the threading process.

3. Maintenance and Troubleshooting

intro paragraph

- Perform regular maintenance on threading equipment, including cleaning, lubrication, and adjustments.

- Troubleshoot and resolve any mechanical or operational issues that arise during threading.

4. Safety and Compliance

intro paragraph

- Adhere to all safety protocols and regulations pertaining to threading operations.

- Maintain a clean, organized, and safe work environment.

Interview Tips

Preparing thoroughly for your interview will significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company’s history, mission, values, and recent developments. Understand the specific requirements of the Heavy Threader role and how your skills align with them.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about current trends and best practices.

2. Practice Your Answers to Common Interview Questions

Anticipate common interview questions and prepare your responses in advance. Practice delivering your answers clearly and concisely. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your experience.

- Tell me about yourself and your experience in the threading industry.

- What are your strengths and weaknesses as a Heavy Threader?

- How do you handle pressure and deadlines?

3. Highlight Your Technical Skills and Knowledge

Emphasize your technical skills and knowledge related to threading machinery, quality control, and troubleshooting. Provide examples of projects or situations where you have successfully applied these skills.

- Discuss your experience with specific threading equipment and software.

- Explain your understanding of thread quality standards and inspection techniques.

4. Showcase Your Safety Awareness and Compliance

Demonstrate your commitment to safety and compliance in the workplace. Explain your understanding of relevant safety protocols and regulations, and provide examples of how you have implemented them in your previous roles.

- Describe your experience with hazard identification and risk assessment.

- Explain how you maintain a clean and organized work environment.

Next Step:

Now that you’re armed with the knowledge of Heavy Threader interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Heavy Threader positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini