Are you gearing up for an interview for a Heel Shaper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Heel Shaper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

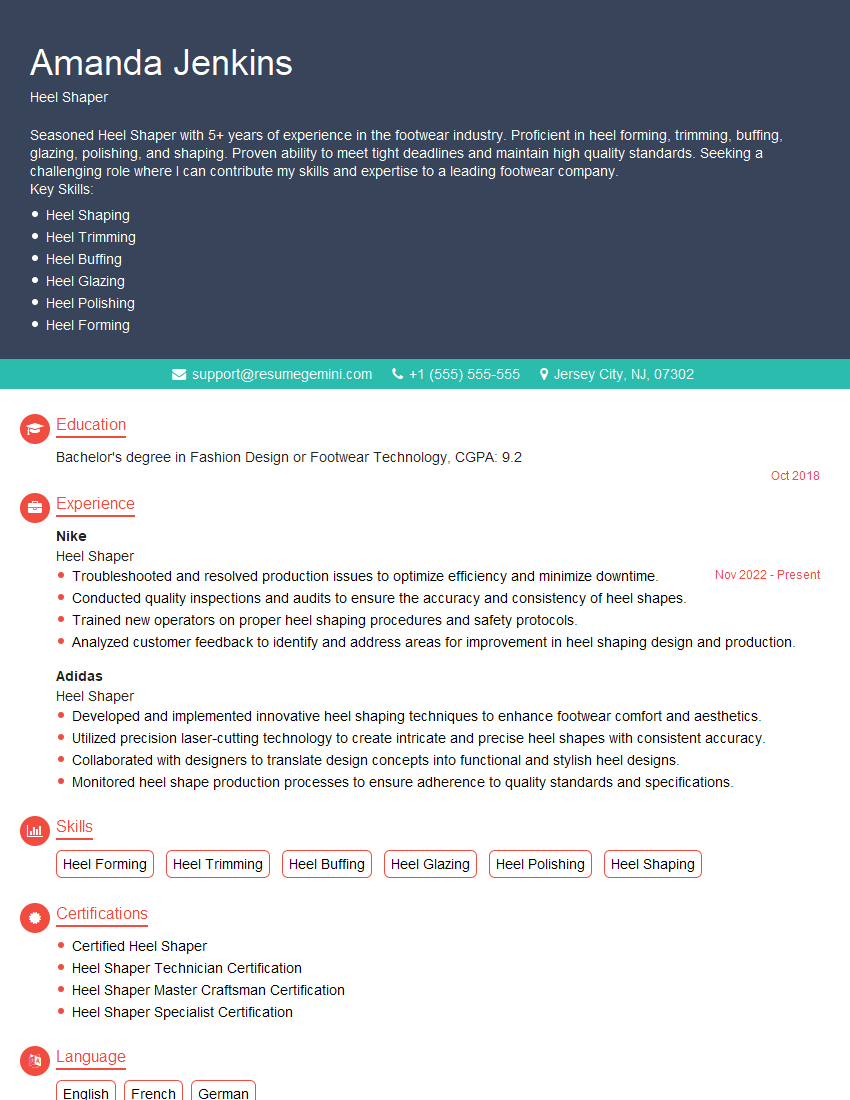

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Heel Shaper

1. How would you measure the precision of a heel shaper?

- Use a micrometer to measure the height and width of the heel at multiple points.

- Calculate the standard deviation of the measurements to determine the precision.

2. What are the different types of heel shapers and their uses?

Mechanical Heel Shapers

- Driven by an electric motor or hydraulic pressure.

- Used for high-volume production in factories.

Handheld Heel Shapers

- Operate manually using a hand crank or lever.

- Suitable for small-scale production or repairs.

Computer-Controlled Heel Shapers

- Programmed with specific heel designs.

- Provide consistent and accurate shaping.

3. How does the geometry of a heel shaper affect the shape of the heel?

- The shape of the shaper’s tip determines the shape of the heel.

- The angle of the shaper’s blade determines the depth and angle of the heel flange.

4. What are the factors to consider when selecting the right heel shaper?

- Type of heel to be shaped

- Production volume

- Required precision and accuracy

- Budget

5. What safety precautions should be taken when operating a heel shaper?

- Wear appropriate safety gear (e.g., gloves, safety glasses).

- Ensure the machine is properly guarded to prevent contact with moving parts.

- Follow manufacturer’s instructions for safe operation and maintenance.

6. How do you maintain and troubleshoot common problems with heel shapers?

- Regularly clean and lubricate the machine.

- Check and adjust the cutting blades as needed.

- Inspect the electrical system and replace any faulty components.

- Refer to the manufacturer’s manual for specific troubleshooting guidance.

7. What is the role of a Heel Shaper in the shoemaking process?

- Shapes the heel to the desired design.

- Ensures the heel fits securely and comfortably on the shoe.

- Contributes to the overall aesthetic and functional quality of the shoe.

8. How do you use a heel shaper to achieve a specific heel shape?

- Select the appropriate shaper tip for the desired heel shape.

- Set the shaper to the correct cutting depth.

- Position the heel on the shaper and secure it in place.

- Operate the shaper to remove excess material and form the desired shape.

9. What are the different grades of sandpaper used in heel shaping and their purposes?

- Coarse (80-120 grit): For removing large amounts of material and rough shaping.

- Medium (150-220 grit): For smoothing out the surface and refining the shape.

- Fine (240-400 grit): For creating a smooth and polished finish.

10. How do you ensure quality control when working with heel shapers?

- Regularly inspect the heel shapers for wear or damage.

- Use calibrated measuring tools to ensure accuracy.

- Train operators on proper techniques and safety procedures.

- Inspect finished heels for defects and compliance with specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Heel Shaper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Heel Shaper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Heel Shaper is responsible for shaping and finishing heels for shoes. The role involves precise craftsmanship and attention to detail to ensure high-quality footwear production.

1. Heel Shaping and Finishing

Utilizing specialized tools and equipment, Heel Shapers shape and smooth heels to achieve the desired contours and dimensions.

- Operate machinery to cut heels from leather or other materials.

- Manually shape and refine heel profiles using specialized tools.

2. Surface Preparation

Prepare heel surfaces for subsequent processes by sanding, buffing, and applying protective coatings.

- Sand and buff heels to remove imperfections and achieve a smooth finish.

- Apply finishes to protect heels from wear and tear and enhance their appearance.

3. Quality Control and Inspection

Inspect heels throughout the shaping process to ensure they meet specifications and aesthetic standards.

- Verify heel dimensions, shape, and surface quality.

- Identify and correct any defects or deviations from design specifications.

4. Safety and Equipment Maintenance

Adhere to safety regulations and maintain equipment used in heel shaping, ensuring a safe and efficient work environment.

- Follow all safety protocols and wear appropriate protective gear.

- Inspect and maintain equipment regularly to ensure proper functioning.

Interview Tips

Preparing for an interview as a Heel Shaper is crucial to showcase your skills and qualifications. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Position

Before the interview, thoroughly research the company you’re applying to and the specific position. This demonstrates your interest and understanding of the role.

- Read the company website, social media pages, and any available press releases.

- Identify the company’s values, goals, and recent developments.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in heel shaping and finishing. Quantify your accomplishments using specific metrics.

- Describe your experience shaping and finishing heels for different types of shoes.

- Mention any specialized techniques or equipment you have proficiency in using.

3. Prepare for Technical Questions

Be prepared to answer questions about heel shaping techniques, materials, and quality control processes. Practice describing your approach to shaping and finishing heels to meet design specifications.

- Review common heel shapes and how to achieve them.

- Explain the importance of surface preparation and finishing for heel durability.

4. Practice Your Presentation

Rehearse answering common interview questions to improve your delivery and confidence. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Describe a situation where you faced a challenge in heel shaping and how you overcame it.

- Explain how you ensure the quality and consistency of your work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Heel Shaper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!