Feeling lost in a sea of interview questions? Landed that dream interview for Hewer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hewer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

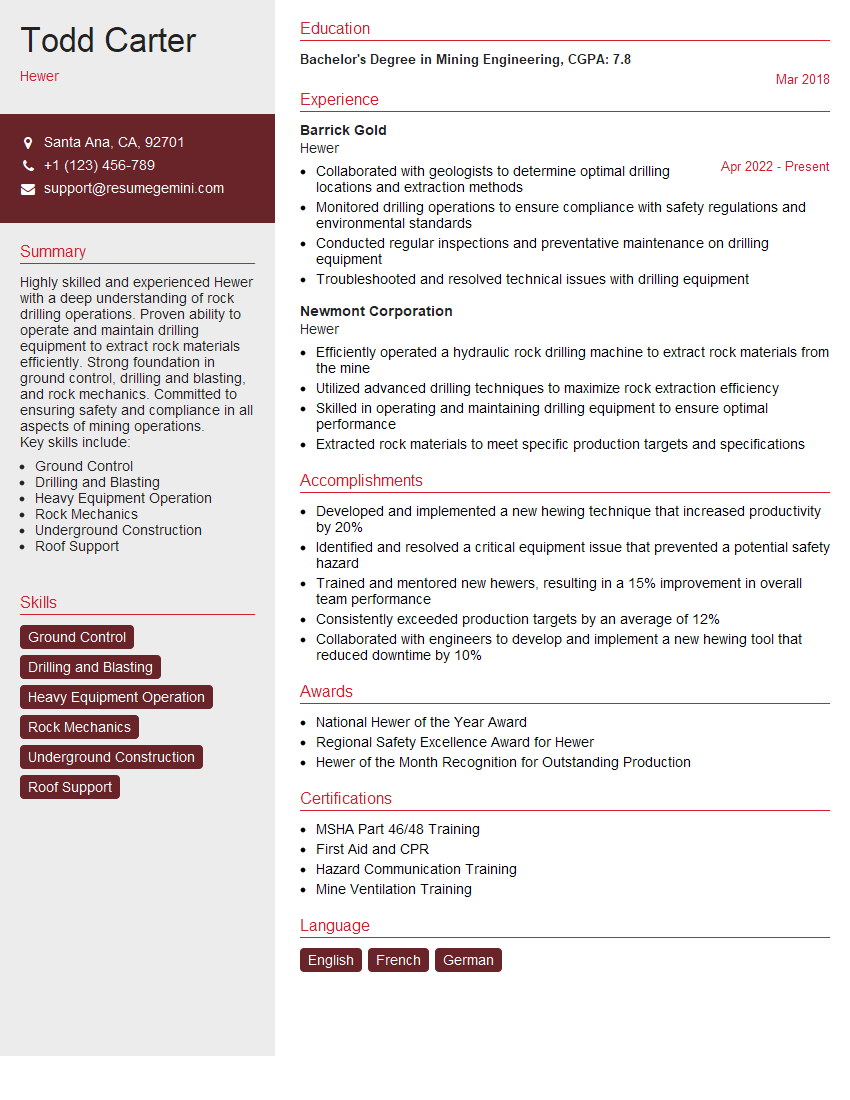

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hewer

1. What are the key components of a hydraulic system and how do they interact?

- Reservoir: Stores the hydraulic fluid and provides a source of fluid for the pump.

- Pump: Moves hydraulic fluid through the system and generates pressure.

- Control valve: Regulates the flow and pressure of the hydraulic fluid.

- Actuator: Converts hydraulic pressure into mechanical force to perform work.

- Lines and hoses: Connect the components of the hydraulic system and allow for the flow of hydraulic fluid.

- Filters: Remove contaminants from the hydraulic fluid to prevent damage to system components.

2. What are the different types of hydraulic pumps and what are their advantages and disadvantages?

Positive displacement pumps

- Gear pumps: Simple design, low cost, high pressure capabilities.

- Vane pumps: High efficiency, low noise, suitable for high speeds.

- Piston pumps: High pressure and flow capabilities, but more complex and expensive.

Rotary pumps

- Centrifugal pumps: High flow rates, but low pressure capabilities.

- Axial piston pumps: High efficiency, variable displacement, used in mobile hydraulics.

3. What are the key factors to consider when designing a hydraulic system?

- Application requirements: Pressure, flow rate, power, and duty cycle.

- Component selection: Pumps, valves, actuators, and other components must be matched to meet system requirements.

- Fluid selection: Type of hydraulic fluid, viscosity, and temperature range must be considered.

- System efficiency: Minimizing pressure drops and energy losses to improve system performance.

- Safety considerations: Protection against overpressure, leaks, and contamination.

4. What are the common troubleshooting techniques used to diagnose and resolve hydraulic system problems?

- Visual inspection: Check for leaks, loose connections, and damaged components.

- Pressure testing: Measure system pressure at key points to identify pressure drops or blockages.

- Flow testing: Determine the flow rate and identify any restrictions or leaks.

- Temperature monitoring: Check fluid temperature to identify overheating or contamination.

- Component testing: Isolate and test individual components to determine if they are functioning properly.

5. What are the latest advancements in hydraulic systems technology?

- Electromechanical actuators: Combining hydraulics with electric motors for increased efficiency and control.

- Proportional valves: Providing precise flow control and energy savings.

- Biodegradable hydraulic fluids: Environmental sustainability.

- Simulation and modeling: Advanced tools for system design and optimization.

- Industry 4.0 integration: Digitalization and data analytics for predictive maintenance and remote monitoring.

6. What is the difference between a closed-loop and an open-loop hydraulic system?

- Closed-loop systems: Feedback from sensors is used to control system operation, providing precise control and stability.

- Open-loop systems: No feedback is used, and system operation is dependent on constant input parameters.

7. What are the safety precautions to follow when working with hydraulic systems?

- Wear appropriate safety gear, including eye protection and gloves.

- Never work on a pressurized system.

- Use proper tools and techniques to prevent injuries.

- Be aware of potential hazards such as leaks, high pressure, and hot surfaces.

- Follow established lockout/tagout procedures.

8. What are the maintenance and inspection procedures for hydraulic systems?

- Regular visual inspections for leaks and damage.

- Periodic pressure and flow testing.

- Fluid analysis to monitor fluid condition and contamination.

- Replacement of filters and seals.

- Lubrication of moving components.

9. What are the environmental considerations for hydraulic systems?

- Use of biodegradable hydraulic fluids.

- Proper disposal of used fluids.

- Energy efficiency to reduce energy consumption.

- Minimizing leaks and spills.

- Compliance with environmental regulations.

10. Can you provide an example of a hydraulic system that you have worked on and describe the challenges and solutions encountered?

- Describe the system, its purpose, and your role in the project.

- Explain the challenges faced, including any technical difficulties or operational issues.

- Outline the solutions implemented, demonstrating your problem-solving skills and technical expertise.

- Highlight the outcomes achieved, such as improved performance, increased efficiency, or reduced downtime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hewers are responsible for cutting down trees and preparing them for transport to the sawmill. They use a variety of tools, including axes, chainsaws, and skidders. Hewers must be physically fit and have a good understanding of tree felling techniques.

1. Tree Felling

Hewers use axes or chainsaws to fell trees. They must be able to assess the tree’s lean, wind direction, and surrounding obstacles to determine the safest and most efficient way to fell the tree.

- Assess tree lean, wind direction, and surrounding obstacles.

- Use proper felling techniques to safely fell trees.

2. Bucking

Hewers use chainsaws to buck felled trees into logs of specific lengths. They must be able to make precise cuts and follow the grain of the wood to avoid splitting or damaging the logs.

- Use chainsaws to buck felled trees into logs.

- Make precise cuts and follow the grain of the wood.

3. Skidding

Hewers use skidders to drag logs to the landing area. They must be able to operate skidders safely and efficiently to avoid damaging the logs or the surrounding environment.

- Use skidders to drag logs to the landing area.

- Operate skidders safely and efficiently.

4. Debarking

Hewers use debarkers to remove the bark from logs. They must be able to operate debarkers safely and efficiently to avoid damaging the logs or the equipment.

- Use debarkers to remove bark from logs.

- Operate debarkers safely and efficiently.

Interview Tips

To ace an interview for a hewer position, candidates should be prepared to discuss their experience and skills in tree felling, bucking, skidding, and debarking. They should also be able to demonstrate their physical fitness and willingness to work in a physically demanding environment.

1. Research the Company

Before the interview, candidates should research the company they are applying to. This will help them understand the company’s values, culture, and business goals. Candidates should also be prepared to discuss how their skills and experience align with the company’s needs.

- Visit the company’s website.

- Read articles about the company in trade publications.

2. Practice Your Answers

Candidates should practice answering common interview questions. This will help them feel more confident and prepared during the interview. Some common interview questions for hewer positions include:

- Tell me about your experience in tree felling.

- What are your strengths and weaknesses as a hewer?

- Why are you interested in working for our company?

3. Dress Professionally

Candidates should dress professionally for the interview. This means wearing clean, pressed clothes and shoes. Candidates should also avoid wearing excessive jewelry or perfume/cologne.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

4. Be on Time

Candidates should be on time for the interview. This shows the interviewer that they are respectful of the interviewer’s time. Candidates should also arrive at the interview location early so they can relax and prepare.

- Plan your route ahead of time.

- Allow extra time for traffic or unexpected delays.

Next Step:

Now that you’re armed with the knowledge of Hewer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hewer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini