Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the High Pressure Compressed Gas Filler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a High Pressure Compressed Gas Filler so you can tailor your answers to impress potential employers.

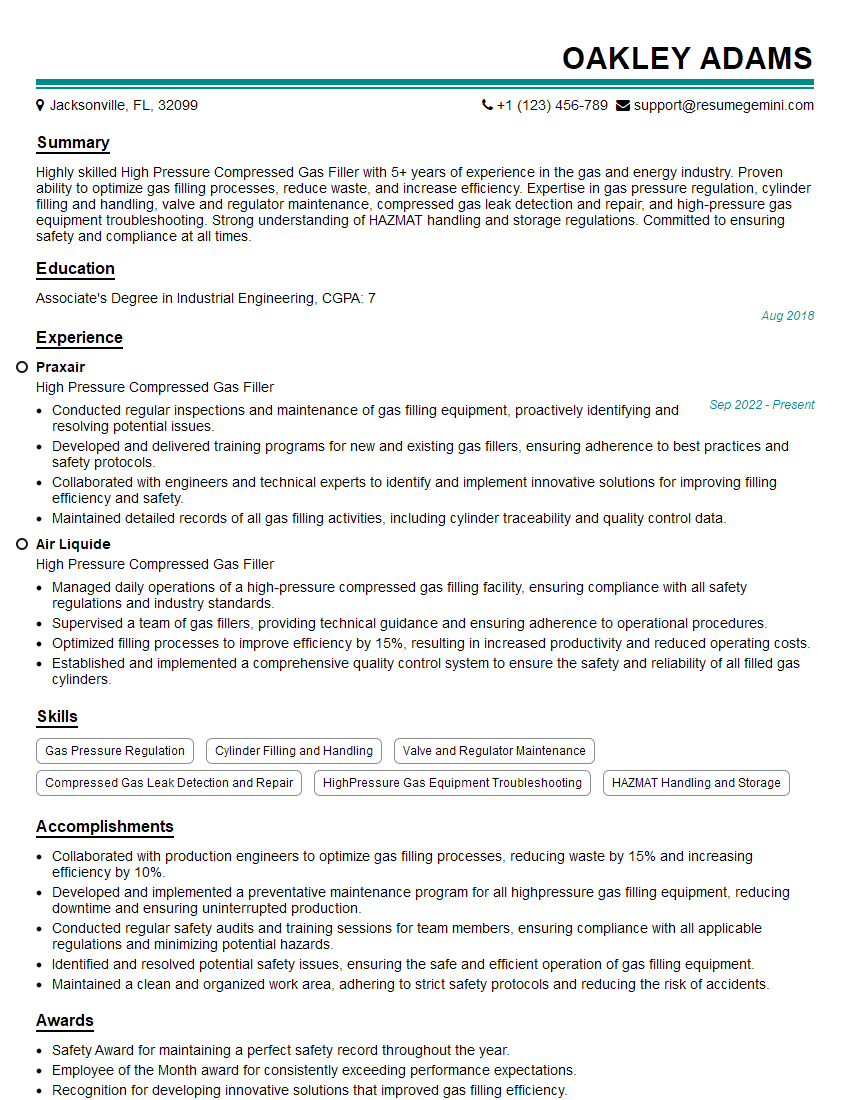

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For High Pressure Compressed Gas Filler

1. What safety precautions should be taken when filling high-pressure compressed gas cylinders?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensure the cylinder is properly secured and grounded.

- Inspect the cylinder for any damage or leaks before filling.

- Never fill a cylinder beyond its rated capacity.

- Slowly open the filling valve and monitor the pressure gauge to prevent overfilling.

- Keep the cylinder cool during filling to prevent pressure buildup.

- Purge the cylinder with the appropriate gas before filling to remove any contaminants.

- Label the cylinder with the correct gas type, pressure, and date.

- Store the filled cylinder in a safe and secure location.

- Train all employees on proper gas filling procedures.

2. What are the different types of high-pressure compressed gas cylinders and their applications?

Type A Cylinders

- Used for gases such as oxygen, nitrogen, and argon.

- Made from seamless aluminum or steel.

- Have a capacity of 300 to 3,000 cubic feet.

Type B Cylinders

- Used for gases such as hydrogen, helium, and acetylene.

- Made from welded steel.

- Have a capacity of 200 to 2,000 cubic feet.

Type C Cylinders

- Used for gases such as chlorine, ammonia, and carbon dioxide.

- Made from cast iron or forged steel.

- Have a capacity of 50 to 1,000 pounds.

3. How do you troubleshoot a high-pressure compressed gas cylinder that is leaking?

- Check the cylinder valve for damage or leaks.

- Inspect the cylinder body for any cracks or holes.

- Tighten the valve packing nut if necessary.

- Replace the valve if it is damaged beyond repair.

- If the leak persists, contact a qualified technician.

4. What are the consequences of overfilling a high-pressure compressed gas cylinder?

- Increased risk of rupture.

- Pressure buildup that can damage the cylinder and regulator.

- Leaks that can release hazardous gas into the environment.

- Injury or death to personnel.

5. What is the maximum fill pressure for a specific high-pressure compressed gas cylinder?

The maximum fill pressure for a specific high-pressure compressed gas cylinder is determined by its design and material of construction. It is typically indicated on the cylinder’s nameplate or in the manufacturer’s specifications. Exceeding the maximum fill pressure can lead to catastrophic failure of the cylinder.

6. What are the different types of valves used on high-pressure compressed gas cylinders?

- Cylinder valves: These valves are located at the top of the cylinder and control the flow of gas into and out of the cylinder.

- Regulator valves: These valves are located on the regulator and control the flow of gas from the cylinder to the equipment being used.

- Check valves: These valves prevent the backflow of gas into the cylinder and can be located in the regulator or on the equipment being used.

7. What causes a high-pressure compressed gas cylinder to rupture?

- Overfilling

- Damage to the cylinder

- Exposure to excessive heat

- Mechanical shock

- Corrosion

8. What are the signs that a high-pressure compressed gas cylinder is defective?

- Rust or corrosion on the cylinder

- Dents or cracks in the cylinder

- Leaking valves

- Loose or missing valve caps

- Damaged threads on the cylinder

9. What training is required to be a High Pressure Compressed Gas Filler?

Training requirements may vary depending on the specific industry and regulations in your area. However, in general, High Pressure Compressed Gas Fillers should receive training in the following areas:

- Gas cylinder safety

- Gas cylinder filling procedures

- Gas cylinder storage and handling

- First aid and emergency response

10. What are the career opportunities for a High Pressure Compressed Gas Filler?

High Pressure Compressed Gas Fillers can find employment in a variety of industries, including:

- Industrial gas suppliers

- Medical gas suppliers

- Firefighting and rescue services

- Manufacturing

- Construction

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for High Pressure Compressed Gas Filler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the High Pressure Compressed Gas Filler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a High Pressure Compressed Gas Filler, you will be responsible for safely and efficiently filling high-pressure compressed gas cylinders. Your key responsibilities will include:

1. Filling High-Pressure Compressed Gas Cylinders

You will be responsible for filling high-pressure compressed gas cylinders in accordance with all applicable safety regulations.

- Following established procedures and safety protocols to ensure the safe filling of cylinders.

- Inspecting cylinders for damage or defects before filling.

2. Maintaining Equipment

You will be responsible for maintaining and troubleshooting equipment used in the filling process.

- Performing regular inspections and maintenance on filling equipment to ensure proper operation.

- Troubleshooting and repairing equipment as needed.

3. Adhering to Safety Regulations

You will be responsible for adhering to all applicable safety regulations and guidelines.

- Wearing appropriate personal protective equipment (PPE).

- Following established safety procedures and protocols.

4. Quality Control

You will be responsible for ensuring the quality of the gas being filled into cylinders.

- Sampling and testing gas to ensure it meets specifications.

- Maintaining records of all quality control activities.

Interview Tips

To help you ace your interview for a High Pressure Compressed Gas Filler position, here are some tips:

1. Research the Company and Position

Take the time to research the company you are interviewing with and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website.

- Read the job description carefully.

2. Prepare for Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare for these questions by brainstorming your answers and practicing them out loud.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions.

- Tailor your answers to the specific job you are applying for.

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the job you are applying for. For example, if you have experience filling high-pressure compressed gas cylinders, be sure to mention this in your interview.

- Use specific examples to demonstrate your skills and experience.

- Quantify your accomplishments whenever possible.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the job and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive at the interview location 5-10 minutes early.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the High Pressure Compressed Gas Filler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.