Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the High Rigger interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a High Rigger so you can tailor your answers to impress potential employers.

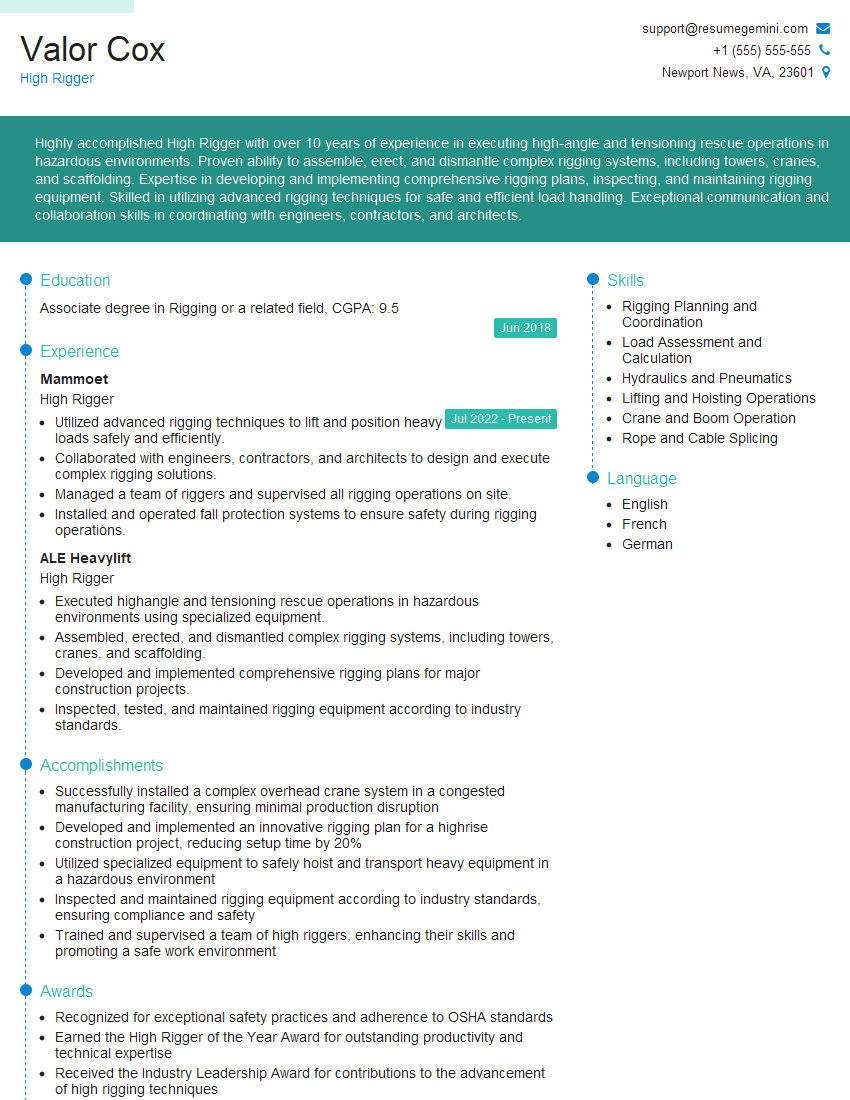

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For High Rigger

1. How do you ensure that the loads are correctly weighted and balanced before lifting?

- Verify the weight of the load using a load scale or dynamometer.

- Calculate the load’s center of gravity and ensure it is within the acceptable range.

- Inspect the rigging hardware and ensure it is in good condition and rated for the load.

- Test the lifting equipment and ensure it is functioning properly.

- Follow the manufacturer’s guidelines for safe lifting procedures.

2. What are the safety precautions you take when working at heights?

Personal Protective Equipment (PPE)

- Wear a hard hat to protect against falling objects.

- Wear safety glasses or goggles to protect against debris.

- Wear gloves to protect hands from abrasions and cuts.

- Wear a safety harness with a lanyard to prevent falls.

- Use fall protection equipment such as guardrails or safety nets.

Work Practices

- Be aware of your surroundings and potential hazards.

- Use proper lifting techniques and avoid overexertion.

- Inspect equipment regularly and report any defects.

- Follow safe work procedures.

- Work with a partner or spotter when possible.

3. How do you inspect and maintain rigging equipment?

- Visually inspect ropes, slings, and chains for damage or wear.

- Check hardware for cracks, corrosion, and deformation.

- Inspect lifting equipment, such as cranes and hoists, according to manufacturer’s guidelines.

- Lubricate and maintain equipment regularly to prevent corrosion and ensure smooth operation.

- Keep records of maintenance and inspections.

4. What is the difference between static and dynamic loads?

- Static loads: Loads that are applied gradually and do not change significantly over time. Example: a weight hanging from a rope.

- Dynamic loads: Loads that are applied suddenly or change rapidly, causing the structure to vibrate or oscillate. Example: a crane lifting and swinging a heavy object.

5. What are the different types of slings used in rigging?

- Nylon slings: Lightweight and flexible, good for general purpose lifting.

- Polyester slings: Stronger and more durable than nylon slings, resistant to chemicals.

- Wire rope slings: Strong and durable, used for heavy lifting.

- Chain slings: Durable and long-lasting, used for heavy lifting and harsh environments.

- Web slings: Flat and flexible, used for delicate or fragile loads.

6. What are the factors that affect the choice of rigging method?

- Weight and size of the load

- Height and distance of the lift

- Type of equipment available

- Environmental conditions

- Safety regulations

7. How do you handle and store slings to prevent damage?

- Store slings in a cool, dry place away from direct sunlight.

- Do not fold or crease slings.

- Inspect slings regularly for damage and discard any damaged slings.

- Do not overload or shock load slings.

- Use proper rigging techniques to minimize wear and tear on slings.

8. What are the procedures for securing a load to a crane hook?

- Inspect the crane hook and sling for damage or defects.

- Attach the sling to the load using a suitable knot or hardware.

- Wrap the sling around the crane hook and secure it with a shackle or hook.

- Test the load by lifting it slightly off the ground.

- Communicate clearly with the crane operator to ensure safe lifting.

9. How do you calculate the safe working load (SWL) of a rigging system?

- Determine the SWL of each component in the rigging system (slings, hardware, etc.).

- Consider the angle of the lift and any reductions in SWL due to angles.

- Multiply the SWL of each component by the appropriate factor of safety.

- The lowest SWL of any component in the system is the SWL of the entire system.

10. What are the safety regulations and standards governing rigging operations?

- OSHA regulations (29 CFR Part 1926)

- ANSI/ASME B30.9: Slings

- ANSI/ASME B30.20: Below-the-Hook Lifting Devices

- ANSI/ASME B30.26: Cranes and Hoists

- Company-specific safety policies and procedures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for High Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the High Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

High Riggers are responsible for the safe and efficient assembly, disassembly, and maintenance of high-rise structures, such as buildings, bridges, and towers. They work at heights, using ropes, pulleys, and other equipment to lift and position heavy materials and components.

1. Assembly and Installation

High Riggers assemble and install various structural components, including beams, columns, and trusses. They follow blueprints and specifications to ensure proper alignment and safety.

2. Dismantling and Removal

High Riggers also dismantle and remove existing structures, such as old buildings or bridges. They use specialized cutting and rigging techniques to safely dismantle and remove components in a controlled manner.

3. Heavy Equipment Operation

High Riggers operate heavy equipment, such as cranes, hoists, and forklifts, to lift and move materials and components. They must be proficient in the safe operation of this equipment.

4. Safety and Compliance

High Riggers prioritize safety in all aspects of their work. They follow stringent safety protocols, including wearing appropriate safety gear, inspecting equipment, and adhering to industry regulations.

Interview Tips

Preparing for a High Rigger interview requires thorough research and a strong understanding of the job responsibilities. Here are some tips and hacks to help candidates ace the interview:

1. Research the Industry and Company

Learn about the latest advancements in high rigging techniques and technologies. Research the company’s projects and safety record to showcase your interest and knowledge.

2. Practice Common Interview Questions

Prepare for common interview questions related to high rigging, such as experience with heavy equipment, safety protocols, and communication skills. Anticipate questions about your understanding of rigging techniques and industry regulations.

3. Highlight Relevant Skills and Experience

Emphasize your skills in assembling, dismantling, and maintaining high-rise structures. Showcase your experience in operating heavy equipment and demonstrate your commitment to safety.

4. Bring Evidence of Certification and Training

If you hold any certifications or have completed specialized training programs, bring copies to the interview. This will demonstrate your qualifications and dedication to professional development.

5. Dress Professionally and Arrive Punctually

Dress appropriately for the interview, typically in business casual or workwear. Arrive on time to show respect for the interviewer and their schedule.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the High Rigger role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.