Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted High Speed Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

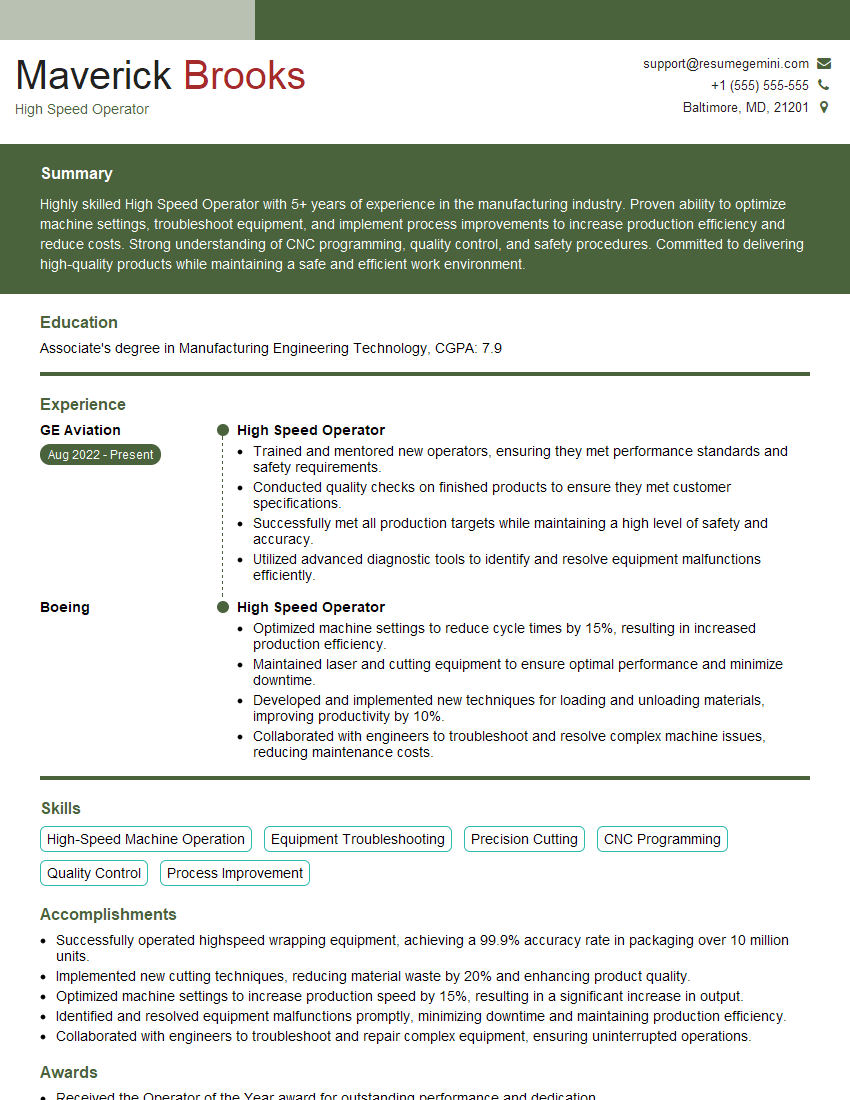

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For High Speed Operator

1. What is your experience in working with high-speed equipment?

I have worked with high-speed equipment for over 5 years. I have experience operating a variety of high-speed machines, including CNC machines, injection molding machines, and printing presses. I am also familiar with the safety procedures and protocols involved in working with high-speed equipment.

2. What are the challenges of working with high-speed equipment?

Safety

- High-speed equipment can be dangerous if it is not operated properly. It is important to be aware of the hazards and to follow all safety procedures.

- Wear appropriate personal protective equipment (PPE) such as safety glasses, earplugs, and gloves.

- Never operate high-speed equipment when you are tired or under the influence of drugs or alcohol.

Technical

- High-speed equipment can be complex and difficult to operate. It is important to have a good understanding of the machine and its controls.

- High-speed equipment can be very fast, so it is important to be able to think quickly and react quickly.

- High-speed equipment can be very loud, so it is important to be able to concentrate and focus in a noisy environment.

3. How do you ensure the quality of the products produced by high-speed equipment?

There are a number of ways to ensure the quality of the products produced by high-speed equipment. These include:

- Using high-quality materials

- Properly calibrating and maintaining the equipment

- Following established procedures

- Inspecting the products regularly

- Taking corrective action when necessary

4. What are the maintenance requirements for high-speed equipment?

The maintenance requirements for high-speed equipment vary depending on the type of equipment. However, some general maintenance tasks that may be required include:

- Regular cleaning and lubrication

- Checking for wear and tear

- Calibrating and adjusting the equipment

- Replacing worn or damaged parts

5. What are the safety precautions that need to be taken when working with high-speed equipment?

There are a number of safety precautions that need to be taken when working with high-speed equipment. These include:

- Wearing appropriate personal protective equipment (PPE)

- Never operating high-speed equipment when you are tired or under the influence of drugs or alcohol

- Being aware of the hazards and following all safety procedures

- Keeping the work area clean and free of debris

- Shutting down the equipment and disconnecting the power before performing any maintenance or repairs

6. What are the different types of high-speed equipment?

There are many different types of high-speed equipment. Some common types include:

- CNC machines

- Injection molding machines

- Printing presses

- Packaging machines

- Textile machines

7. What are the advantages of using high-speed equipment?

There are many advantages to using high-speed equipment. These include:

- Increased productivity

- Improved quality

- Reduced costs

- Faster time to market

- Enhanced competitiveness

8. What are the disadvantages of using high-speed equipment?

There are also some disadvantages to using high-speed equipment. These include:

- Higher cost

- Increased complexity

- Greater risk of accidents

- Need for specialized training

- Increased maintenance requirements

9. What are the latest trends in high-speed equipment?

The latest trends in high-speed equipment include:

- Increased use of automation

- Development of more efficient and reliable machines

- Integration of new technologies, such as the Internet of Things (IoT)

- Growing demand for high-speed equipment in emerging markets

- Focus on sustainability and energy efficiency

10. What are the future prospects for high-speed equipment?

The future prospects for high-speed equipment are very positive. The demand for high-speed equipment is expected to continue to grow in the coming years, driven by the increasing need for productivity, quality, and speed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for High Speed Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the High Speed Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

High Speed Operators play a crucial role in the manufacturing industry, operating specialized equipment at high speeds to produce precision components. Their responsibilities encompass a range of technical and operational aspects, requiring expertise in equipment operation, quality control, and safety protocols.

1. Equipment Operation

High Speed Operators are responsible for the safe and efficient operation of high-speed machinery, such as CNC machines, lathes, and milling machines.

- Set up and configure machines according to specifications and production schedules.

- Monitor and adjust machine parameters, ensuring optimal performance and product quality.

- Troubleshoot and resolve equipment malfunctions or breakdowns promptly.

2. Quality Control

High Speed Operators ensure that products meet specified quality standards and tolerances.

- Inspect products for defects and deviations from specifications.

- Identify and correct errors or nonconformances in the production process.

- Maintain accurate records of quality control data and reports.

3. Safety and Compliance

High Speed Operators adhere to strict safety guidelines to ensure a safe and compliant work environment.

- Wear appropriate personal protective equipment (PPE).

- Follow established safety procedures and regulations.

- Report any potential hazards or safety concerns to supervisors.

4. Communication and Teamwork

High Speed Operators collaborate effectively with colleagues, supervisors, and engineers.

- Communicate production updates, machine status, and quality issues.

- Collaborate with team members to resolve complex technical challenges.

- Participate in training and development programs to enhance skills and knowledge.

Interview Tips

To ace the interview for a High Speed Operator position, it’s essential to showcase your technical expertise, problem-solving abilities, and commitment to safety. Here are some interview preparation tips to help you succeed:

1. Research the Company and Industry

Familiarize yourself with the company’s core business, products, and industry trends. This will demonstrate your genuine interest in the role and your understanding of the industry.

- Visit the company’s website and social media pages.

- Read recent news articles and industry publications.

- Prepare questions that show your interest in the company’s operations.

2. Highlight Your Technical Expertise

Emphasize your proficiency in operating high-speed machinery and your ability to produce high-quality products. Use specific examples and demonstrate your understanding of machine configurations, troubleshooting techniques, and quality control processes.

- Describe your experience with different types of high-speed machines.

- Explain your process for identifying and correcting production errors.

- Showcase your knowledge of industry-specific tools and technologies.

3. Demonstrate Your Problem-Solving Abilities

Interviewers are keen to assess your ability to handle challenges and find solutions. Share examples of how you have resolved technical issues, improved production efficiency, or contributed to quality improvement initiatives.

- Describe a situation where you identified and resolved a machine malfunction.

- Explain how you increased production output while maintaining quality standards.

- Share an example of how you identified a process improvement opportunity.

4. Emphasize Your Commitment to Safety

Safety is paramount in manufacturing environments. Highlight your commitment to adhering to safety regulations and maintaining a safe and compliant work area.

- Explain your understanding of safety protocols and procedures.

- Share examples of how you have promoted safety in your previous roles.

- Demonstrate your willingness to follow instructions and report any potential hazards.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the High Speed Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.