Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hob Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hob Machine Operator so you can tailor your answers to impress potential employers.

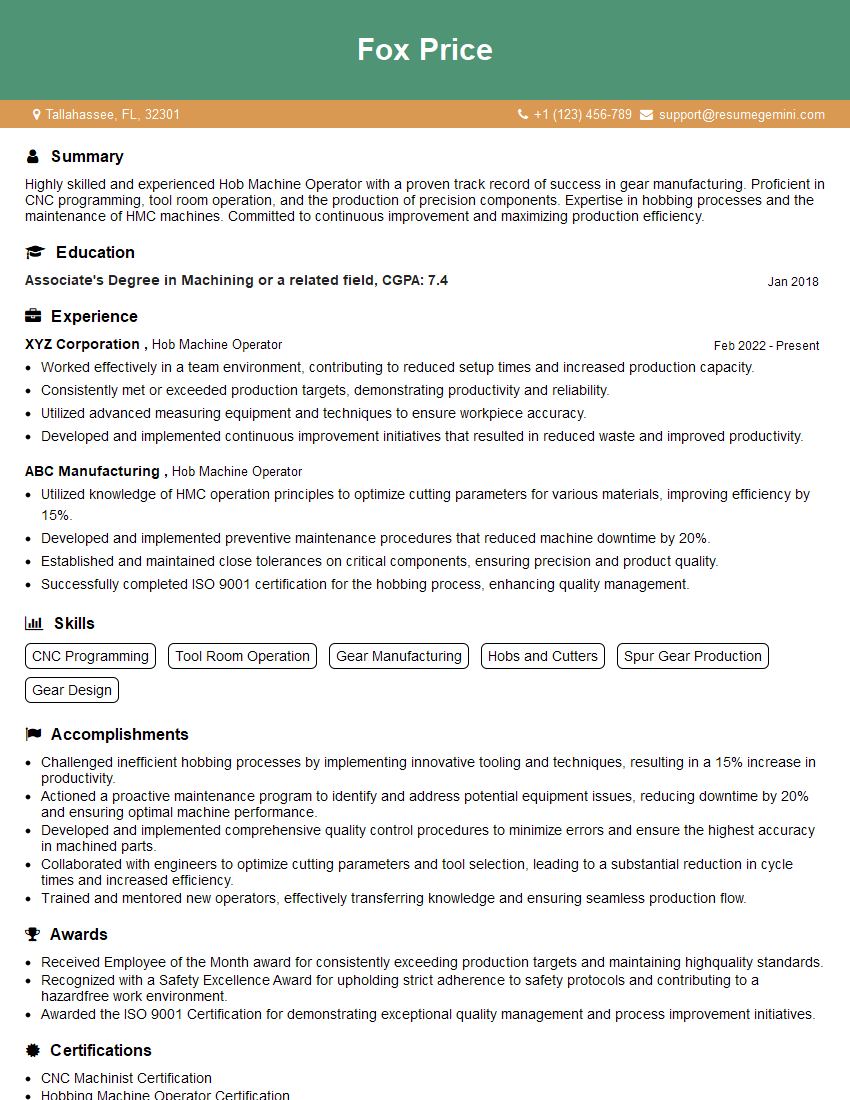

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hob Machine Operator

1. Explain the process of setting up and operating a hobbing machine?

To set up and operate a hobbing machine, I follow a systematic process:

- Machine Preparation: I ensure the machine is clean and ready for operation. I mount the hob and workpiece on the machine, aligning them properly.

- Parameter Setting: I input the cutting parameters, such as speed, feed rate, and depth of cut, into the machine’s control system.

- Lubrication: I apply cutting fluid to the hob and workpiece to reduce friction and improve tool life.

- Hobbing Operation: I initiate the hobbing process, monitoring the machine’s performance and making adjustments as needed.

- Inspection: Once the process is complete, I inspect the finished part for accuracy and quality, ensuring it meets the specified tolerances.

2. Describe the different types of hobs and their applications?

- Involute Hobs: Used for cutting gears with involute tooth profiles, commonly found in power transmission applications.

- Straight Hobs: Cut gears with straight teeth, typically used in low-power or non-power applications.

- Spline Hobs: Design spline shafts and other splined components, used in various mechanical systems.

- Barrel Hobs: Create non-involute tooth profiles, such as barrel teeth found in clutches and ratchets.

- Helical Hobs: Cut helical gears, providing smoother transmission of motion and reduced noise.

3. What are the key factors to consider when selecting the appropriate hob for a specific job?

- Gear Tooth Profile: Match the hob profile to the desired gear tooth profile, such as involute or straight.

- Material: Choose a hob material that can withstand the hardness and abrasiveness of the workpiece material.

- Number of Teeth: Select a hob with a number of teeth that matches the number of teeth in the gear being cut.

- Feed Rate and Speed: Determine the appropriate feed rate and speed based on the workpiece material, hob size, and desired surface finish.

- Workpiece Size and Shape: Consider the size and shape of the workpiece to ensure the hob can access and cut the desired area.

4. Explain the importance of hob maintenance and how you ensure hob sharpness?

Maintaining hob sharpness is crucial for achieving precise and efficient hobbing. I follow these practices:

- Regular Inspection: I visually inspect hobs for wear, damage, or dullness before each use.

- Cleaning: I clean hobs thoroughly to remove any debris or cutting fluid residue.

- Sharpening: I use a hob sharpening machine to sharpen dull hobs, ensuring they maintain optimal cutting edges.

- Storage: I store hobs properly in a controlled environment to prevent corrosion and damage.

5. Describe the different methods of hobbing and their advantages?

- Conventional Hobbing: The hob rotates in the same direction as the workpiece, resulting in a more aggressive cut.

- Climb Hobbing: The hob rotates in the opposite direction of the workpiece, providing a smoother cut and extended hob life.

- End Hobbing: A special hob designed to cut gears from the end, used for gears with large face widths.

- Thread Hobbing: A specialized hobbing process for cutting internal or external threads on workpieces.

6. How do you handle errors or defects that may occur during hobbing?

- Visual Inspection: I visually inspect the finished part for any visible defects or deviations from specifications.

- Dimensional Verification: I use measuring instruments, such as calipers or micrometers, to verify part dimensions and ensure they meet tolerances.

- Root Cause Analysis: I identify the potential causes of defects, such as worn hobs, incorrect setup, or material issues.

- Corrective Action: I implement appropriate corrective actions, such as replacing worn hobs, adjusting machine parameters, or addressing material quality issues.

- Process Optimization: I analyze the process and make necessary improvements to minimize the recurrence of defects.

7. Can you explain the importance of coolant during the hobbing process?

Coolant plays a vital role in hobbing for several reasons:

- Temperature Control: Coolant absorbs heat generated during cutting, preventing excessive heat buildup in the workpiece and hob.

- Lubrication: Coolant reduces friction between the hob and workpiece, improving tool life and surface finish.

- Chip Removal: Coolant helps flush away metal chips from the cutting zone, reducing tool wear and improving cutting efficiency.

- Corrosion Prevention: Coolant provides a protective layer on the workpiece and hob, minimizing corrosion.

8. How do you ensure that the hobbed gears meet the required quality standards?

- Regular Calibration: I calibrate the hobbing machine and measuring instruments regularly to ensure accuracy and precision.

- Process Monitoring: I closely monitor the hobbing process, including parameters like feed rate, speed, and cutting fluid flow.

- Statistical Process Control (SPC): I use SPC techniques to analyze and control the hobbing process, reducing variation and improving product quality.

- Inspection and Verification: I follow a rigorous inspection process, using measuring instruments and gauges to verify the dimensions, tooth profile, and surface finish of hobbed gears.

9. Describe your experience with programming and operating CNC hobbing machines?

I have extensive experience in programming and operating CNC hobbing machines. I am proficient in:

- CNC Code Generation: Using CAM software or manual programming to generate CNC code for complex hobbing operations.

- Machine Setup and Operation: Setting up and operating CNC hobbing machines, including tool loading, workpiece fixturing, and program execution.

- Process Optimization: Analyzing and optimizing CNC hobbing programs for improved efficiency and quality.

- Error Handling and Troubleshooting: Diagnosing and resolving errors that may occur during CNC hobbing operations.

10. How do you stay up-to-date with the latest advancements in hobbing technology?

- Industry Journals and Publications: I regularly read trade journals and publications to stay informed about new technologies and best practices.

- Training and Seminars: I attend training sessions and seminars organized by hobbing machine manufacturers and industry associations.

- Online Resources: I utilize online forums and technical websites to connect with fellow hobbing professionals and learn about emerging trends.

- Collaboration with Suppliers: I maintain close relationships with suppliers to gain insights into the latest hobbing equipment and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hob Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hob Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hob Machine Operator is a skilled professional responsible for operating hobbing machines used in producing gears and splines. Their key job responsibilities include:

1. Machine Operation

Operate hobbing machines to cut gears and splines according to specified dimensions and tolerances.

- Set up and adjust hobbing machines for each job.

- Load and secure workpieces onto the machine.

- Monitor the cutting process and make adjustments as needed.

- Unload finished workpieces and inspect them for quality.

2. Tooling and Maintenance

Maintain and replace cutting tools and other machine components as necessary.

- Sharpen and replace hobs (cutting tools).

- Lubricate and clean machines and tools.

- Troubleshoot and resolve machine malfunctions.

3. Quality Control

Inspect finished workpieces to ensure they meet specifications and tolerances.

- Use measuring tools and gauges to check dimensions and surface finish.

- Identify and correct any defects or non-conformances.

4. Production Planning and Optimization

Plan and optimize production schedules to meet deadlines and minimize downtime.

- Estimate production times and material requirements.

- Coordinate with other departments to ensure smooth workflow.

Interview Tips

To ace a job interview as a Hob Machine Operator, consider the following tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific position you are applying for. This will demonstrate your interest and understanding of the role and company culture.

- Visit the company’s website to learn about their products, services, and mission.

- Read industry news and articles to stay informed about current trends and technologies.

2. Highlight Relevant Experience and Skills

Tailor your resume and interview responses to emphasize your relevant experience and skills. Quantify your accomplishments whenever possible using specific numbers and metrics.

- Showcase your experience operating hobbing machines and producing gears and splines.

- Emphasize your knowledge of tooling and maintenance procedures.

- Highlight your quality control and inspection skills.

3. Be Prepared for Technical Questions

Expect to be asked technical questions during the interview. These questions may cover topics such as:

- Types of hobbing machines and their uses.

- Cutting tool selection and sharpening techniques.

- Quality control methods and inspection equipment.

- Troubleshooting common machine problems.

4. Practice Your Responses

Take time to practice answering common interview questions. This will help you articulate your answers clearly and confidently.

- Prepare a brief introduction of yourself and your experience.

- Practice answering questions about your strengths, weaknesses, and why you are interested in the position.

5. Dress Professionally and Be Punctual

Make a positive first impression by dressing professionally and arriving on time for the interview. This shows respect for the interviewer and company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hob Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.