Feeling lost in a sea of interview questions? Landed that dream interview for Hobbing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hobbing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

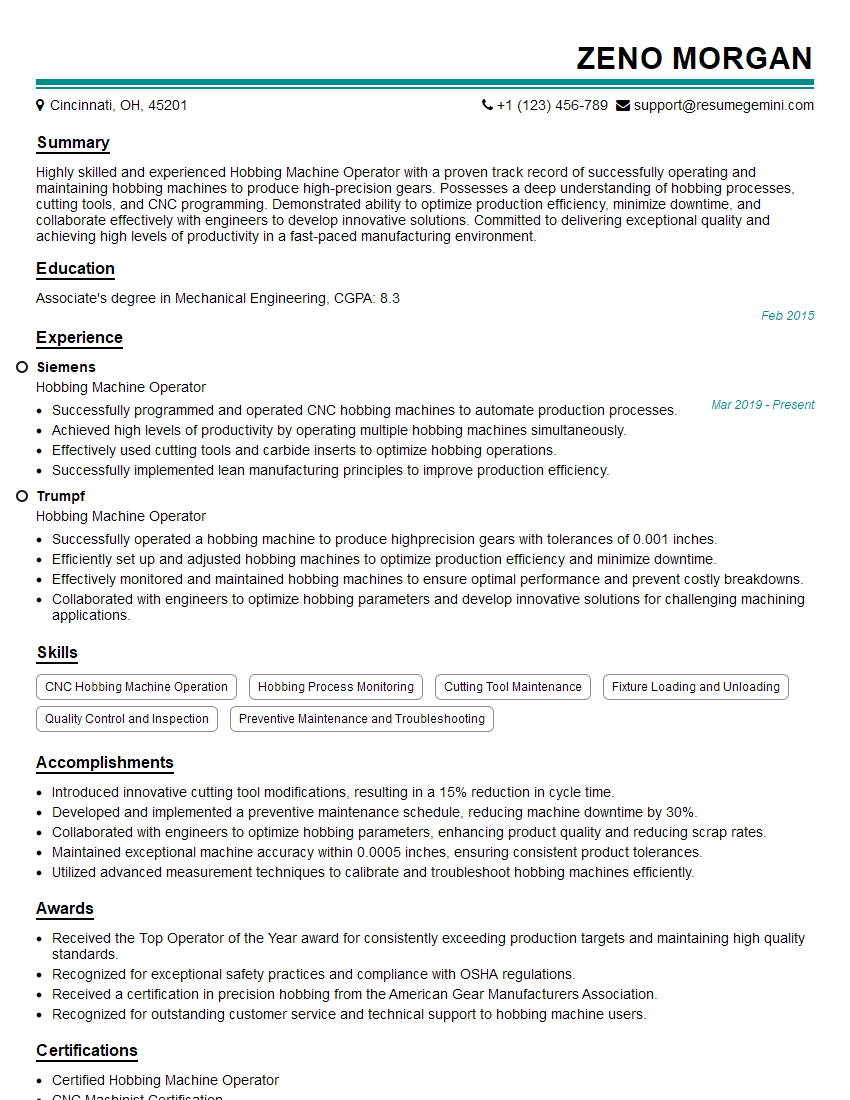

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hobbing Machine Operator

1. Explain the hobbing process?

- Hobbing is a metal cutting process that uses a rotating cutting tool called a hob to cut gears. The hob is shaped like the desired gear, and it is pressed into the workpiece as it rotates.

- The hobbing process can be used to cut gears of various sizes and shapes. It is a relatively fast and efficient process, and it can produce high-quality gears.

2. What are the different types of hobbing machines?

Conventional hobbing machines

- Conventional hobbing machines use a single-point cutting tool to cut gears.

- The cutting tool is mounted on a spindle that rotates around the workpiece.

- The workpiece is mounted on a table that moves in a linear direction.

CNC hobbing machines

- CNC hobbing machines use a computer-controlled cutting tool to cut gears.

- The cutting tool is mounted on a spindle that rotates around the workpiece.

- The workpiece is mounted on a table that moves in a linear direction.

- CNC hobbing machines are more accurate and efficient than conventional hobbing machines.

3. What are the advantages of hobbing over other gear cutting processes?

- Hobbing is a relatively fast and efficient process.

- Hobbing can produce high-quality gears.

- Hobbing is a versatile process that can be used to cut gears of various sizes and shapes.

4. What are the disadvantages of hobbing?

- Hobbing can be a relatively expensive process.

- Hobbing can be a noisy process.

- Hobbing can produce a lot of chips.

5. What are the safety precautions that must be taken when operating a hobbing machine?

- Wear appropriate safety gear, such as safety glasses, earplugs, and gloves.

- Keep the work area clean and free of debris.

- Secure the workpiece properly before starting the machine.

- Never operate the machine with the guards removed.

- Be aware of the machine’s moving parts and keep your hands away from them.

6. What are the different types of hobs?

- Solid hobs

- Inserted hobs

- Shell hobs

7. How do you select the right hob for a particular job?

Factors to consider when selecting a hob:

- The size and shape of the gear to be cut.

- The material of the workpiece.

- The desired surface finish.

- The required production rate.

8. How do you set up a hobbing machine?

Steps for setting up a hobbing machine

- Mount the hob on the spindle.

- Mount the workpiece on the table.

- Set the machine parameters, such as the speed, feed, and depth of cut.

- Start the machine and hob the gear.

9. How do you troubleshoot a hobbing machine?

Common problems that can occur with hobbing machines

- The hob is not cutting properly.

- The workpiece is not being fed properly.

- The machine is making a lot of noise.

- The machine is not producing gears of the desired quality.

10. What are the maintenance procedures for a hobbing machine?

Regular maintenance procedures

- Clean the machine regularly.

- Lubricate the moving parts.

- Check the hob for wear and tear.

- Calibrate the machine regularly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hobbing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hobbing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hobbing Machine Operators play a crucial role in manufacturing industries, operating specialized machines to produce complex gears and other components. Their primary responsibilities include:

1. Machine Operation and Setup

• Set up and operate hobbing machines according to blueprints and specifications

• Select and install appropriate tooling, including hobs, arbors, and fixtures

• Adjust machine settings for cutting speed, feed rate, and depth of cut

2. Quality Control and Inspection

• Conduct visual and dimensional inspections of finished parts against specifications

• Use measuring tools and gauges to ensure accuracy and conformance to standards

• Identify and correct any defects or deviations from specified tolerances

3. Maintenance and Troubleshooting

• Perform routine maintenance on hobbing machines, including lubrication, cleaning, and adjustments

• Troubleshoot machine malfunctions and resolve operational issues

• Identify and replace worn or damaged parts as required

4. Production Monitoring and Optimization

• Monitor machine performance and adjust parameters to maximize productivity and efficiency

• Identify and implement process improvements to reduce cycle times and increase output

• Work within established timeframes and meet production targets

Interview Tips

Ace your Hobbing Machine Operator interview with these key tips:

1. Research the Company and Position

Visit the company website, review their products or services, and learn about their industry. Tailor your answers to demonstrate your understanding of their business and how your skills fit their needs.

Review the job description thoroughly to identify specific skills, experience, and qualifications required for the role.

2. Highlight Your Technical Abilities

Emphasize your proficiency in hobbing machine operation, including setup, tooling selection, and parameter adjustment.

Showcase your knowledge of quality control techniques and your ability to ensure product accuracy and conformance to specifications.

3. Demonstrate Problem-Solving Skills

Provide examples of how you have successfully troubleshooted machine malfunctions and resolved operational issues.

Highlight your ability to identify the root cause of problems and implement effective solutions.

4. Emphasize Teamwork and Communication

Explain how you have effectively worked in a team environment and collaborated with colleagues to achieve common goals.

Discuss your communication skills and ability to work with engineers, supervisors, and other team members.

5. Prepare Questions

Show enthusiasm and interest by preparing questions for the interviewer. This demonstrates your engagement and eagerness to learn more about the company and the position.

Example Outline:

- Tell me more about the company’s manufacturing process and the role of this position within the team.

- Can you describe the typical daily or weekly responsibilities of a Hobbing Machine Operator in this company?

- What opportunities are there for professional development and advancement within the company?

- What are the company’s expectations for productivity and quality standards?

- What are the key challenges and rewards of working as a Hobbing Machine Operator in this industry?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hobbing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.