Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hobbing Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

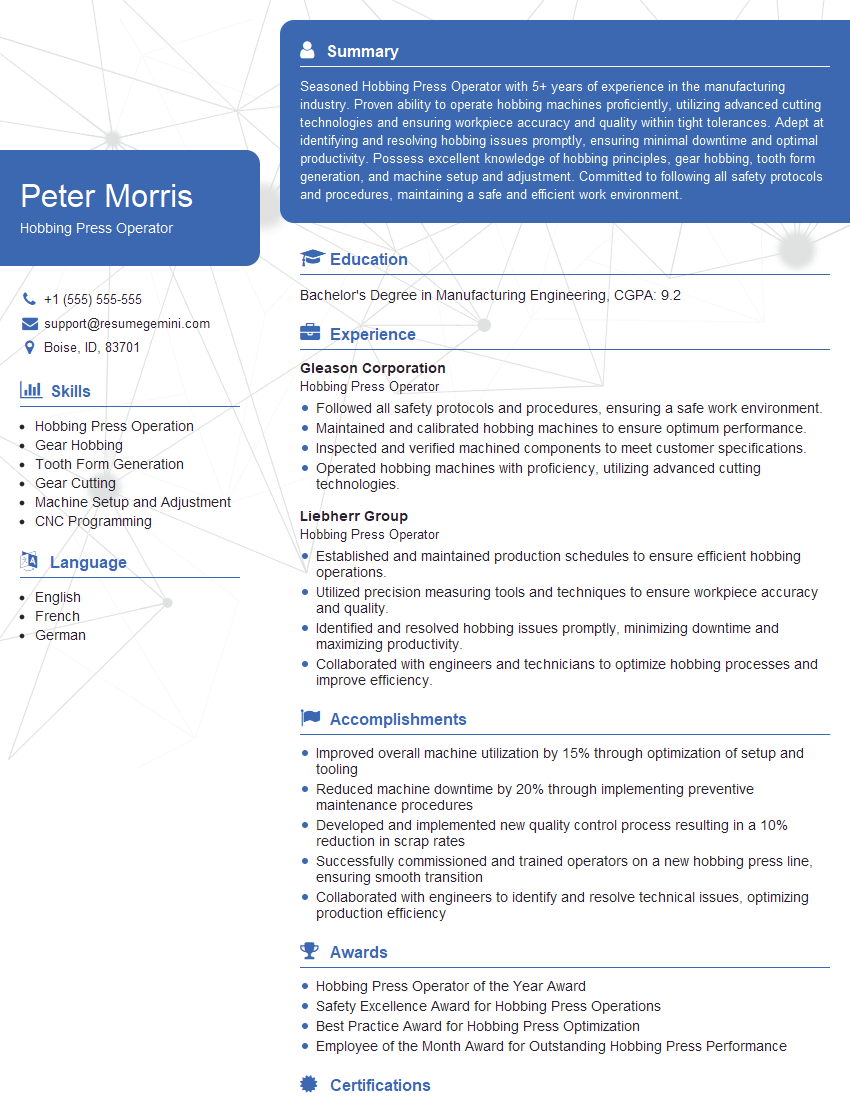

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hobbing Press Operator

1. Describe the process of setting up a hobbing press?

Setting up a hobbing press involves several steps:

- Mount the hob on the hobbing spindle.

- Align the hob with the workpiece.

- Set the cutting depth and feed rate.

- Secure the workpiece in place.

- Start the hobbing process.

2. What are the different types of hobs?

Spur hobs

- Used to cut straight-sided gears.

- Have a series of teeth cut around the circumference of the hob.

Helical hobs

- Used to cut helical gears.

- Have a series of teeth cut at an angle around the circumference of the hob.

Worm hobs

- Used to cut worm gears.

- Have a series of teeth cut in a spiral pattern around the circumference of the hob.

3. What are the factors that affect the quality of a hobbed gear?

- Hob quality

- Workpiece material

- Cutting speed

- Feed rate

- Coolant

4. How do you measure the accuracy of a hobbed gear?

Tooth profile accuracy

- Measured using a gear measuring machine.

- Checks the shape and size of the gear teeth.

Tooth spacing accuracy

- Measured using a gear tooth caliper.

- Checks the distance between the gear teeth.

Runout accuracy

- Measured using a dial indicator.

- Checks the amount of wobble in the gear.

5. How do you troubleshoot a hobbing press?

Excessive noise

- Check for worn or damaged gears.

- Check for loose bearings.

- Check for misalignment.

Poor surface finish

- Check for worn or damaged hobs.

- Check for incorrect cutting speed or feed rate.

- Check for insufficient coolant.

Inaccurate gears

- Check for worn or damaged hobs.

- Check for incorrect setup.

- Check for workpiece material variations.

6. What is the difference between hobbing and shaping?

- Hobbing is a continuous cutting process that uses a hob to cut gears.

- Shaping is an intermittent cutting process that uses a shaper cutter to cut gears.

- Hobbing is generally faster and more efficient than shaping.

7. What are the safety precautions that must be taken when operating a hobbing press?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Never operate the press with the guards removed.

- Be aware of the moving parts of the press and keep hands clear.

- Follow all manufacturer’s instructions for safe operation.

8. How do you calculate the cutting speed for a hobbing operation?

The cutting speed is calculated using the following formula:

Cutting speed = (pi * hob diameter * RPM) / 12

- Cutting speed is measured in feet per minute (fpm).

- Hob diameter is measured in inches.

- RPM is the speed of the hob in revolutions per minute.

9. How do you calculate the feed rate for a hobbing operation?

The feed rate is calculated using the following formula:

Feed rate = (cutting speed * number of teeth on the hob) / (number of starts on the hob * hob diameter)

- Feed rate is measured in inches per minute (ipm).

- Cutting speed is measured in feet per minute (fpm).

- Number of teeth on the hob is the number of cutting teeth on the hob.

- Number of starts on the hob is the number of cutting starts on the hob.

- Hob diameter is measured in inches.

10. How do you maintain a hobbing press?

- Clean the press regularly.

- Lubricate the moving parts of the press.

- Inspect the press for wear and damage.

- Replace worn or damaged parts as needed.

- Follow all manufacturer’s instructions for maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hobbing Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hobbing Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hobbing Press Operators are responsible for operating and maintaining hobbing presses, which are used to create gears and other precision components. Their primary duties include:

1. Setup and Operation

Operators set up and operate hobbing presses according to specifications, ensuring proper tooling and workpiece alignment.

- Adjust machine settings, including speed, feed, and depth of cut.

- Load and secure workpieces into the press.

- Monitor the hobbing process and make necessary adjustments.

2. Quality Inspection

Operators inspect finished parts to ensure they meet quality specifications, using measuring tools and gauges.

- Check dimensions, tolerances, and surface finish.

- Identify and correct any defects or inconsistencies.

3. Maintenance and Repair

Operators perform routine maintenance and minor repairs on hobbing presses, ensuring optimal performance.

- Lubricate and clean machines.

- Troubleshoot and resolve common problems.

- Report major issues to supervisors.

4. Safety Compliance

Operators follow established safety protocols to minimize risks in the workplace.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures.

- Maintain a clean and organized work area.

Interview Tips

To prepare for a hobbing press operator interview, candidates should focus on demonstrating their technical skills, attention to detail, and safety awareness. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Research the company’s industry, products, and culture to understand their business objectives. Review the job description thoroughly to identify specific requirements and qualifications.

- Visit the company website and social media pages.

- Read industry news and articles.

2. Highlight Relevant Experience

Emphasize your previous experience operating hobbing presses or similar equipment. Quantify your accomplishments using specific metrics whenever possible.

- Describe the types of gears or components you have produced.

- Explain your role in quality control and defect prevention.

- Share examples of successful maintenance and repair tasks.

3. Demonstrate Technical Knowledge

Demonstrate your understanding of hobbing press principles, tooling, and cutting parameters. Be prepared to discuss your knowledge of different types of gears and gear manufacturing processes.

- Explain the difference between spur gears, helical gears, and bevel gears.

- Describe the process of hobbing a gear, including setup and tooling selection.

- Discuss common problems encountered during hobbing and troubleshooting techniques.

4. Emphasize Safety and Quality

Highlight your commitment to safety and quality assurance. Discuss your experience with safety protocols and quality control procedures in previous roles.

- Describe your understanding of OSHA regulations for hobbing press operation.

- Explain your methods for ensuring product quality and minimizing defects.

- Share examples of how you have improved safety or efficiency in a previous work environment.

5. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer demonstrates your interest in the position and company. It also gives you an opportunity to clarify any aspects of the job or company culture.

- Ask about the company’s current projects or plans for growth.

- Inquire about the safety record and training opportunities available.

- Ask for details about the team you would be working with.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hobbing Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.