Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hoist Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

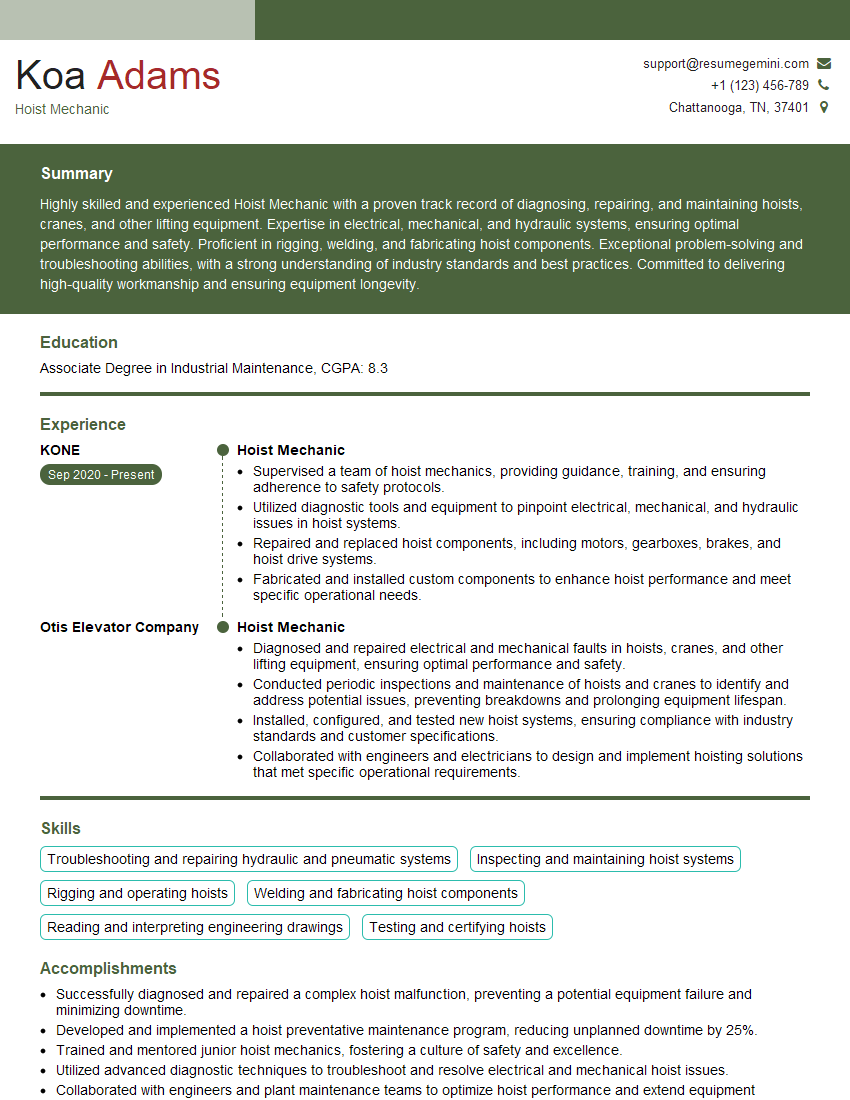

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hoist Mechanic

1. What is the purpose of a hoist limit switch?

The purpose of a hoist limit switch is to prevent the hoist from over traveling in either the up or down direction. It is a safety device that helps to protect the hoist, the load, and the personnel working in the area.

2. How do you troubleshoot a hoist that is not lifting?

Electrical troubleshooting

- Check the power supply to the hoist.

- Check the fuses and circuit breakers.

- Check the wiring for any loose connections or damage.

Mechanical troubleshooting

- Check the hoist brake for proper operation.

- Check the hoist motor for any damage or overheating.

- Check the hoist gearbox for any damage or leaks.

3. What is the difference between a wire rope hoist and a chain hoist?

Wire rope hoists are typically used for heavier loads, while chain hoists are used for lighter loads. Wire rope hoists are more durable and can withstand higher temperatures than chain hoists. Chain hoists are less expensive and easier to maintain than wire rope hoists.

4. What are the different types of hoist brakes?

- Mechanical brakes

- Hydraulic brakes

- Electric brakes

- Pneumatic brakes

5. What are the safety precautions that must be taken when working with hoists?

- Inspect the hoist before each use.

- Do not overload the hoist.

- Do not operate the hoist in a hazardous environment.

- Do not leave the hoist unattended while it is operating.

- Follow the manufacturer’s instructions for operating and maintaining the hoist.

6. What is the purpose of a hoist gearbox?

The purpose of a hoist gearbox is to reduce the speed of the hoist motor and to increase the torque. This allows the hoist to lift heavy loads with a relatively small motor.

7. How do you calculate the safe working load of a hoist?

The safe working load of a hoist is determined by the manufacturer and is based on the following factors:

- The type of hoist

- The capacity of the hoist

- The condition of the hoist

- The environment in which the hoist is being used

8. What are the different types of hoist controls?

- Pendant controls

- Radio controls

- Wired controls

- Remote controls

9. What is the difference between a single-speed hoist and a two-speed hoist?

A single-speed hoist has one speed, while a two-speed hoist has two speeds. Two-speed hoists are more versatile and can be used for a wider range of applications.

10. What is the importance of regular hoist maintenance?

Regular hoist maintenance is important for the following reasons:

- To ensure the safety of the hoist and the personnel working with it.

- To extend the life of the hoist.

- To prevent costly repairs.

- To maintain the hoist’s efficiency and performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hoist Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hoist Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hoist Mechanics, also known as Crane Mechanics, play a crucial role in maintaining and repairing various types of hoists and cranes used in industrial settings. Their primary responsibility is to ensure the safe and efficient operation of these essential equipment.

1. Maintenance and Inspection

Hoist Mechanics conduct regular inspections of hoists and cranes to identify potential problems and prevent breakdowns. They check for any signs of wear, damage, or misalignment in components such as cables, sheaves, motors, and brakes. They also perform routine maintenance tasks to keep the equipment in optimal condition, including lubrication, cleaning, and adjustments.

2. Repair and Troubleshooting

When problems occur with hoists or cranes, Hoist Mechanics are responsible for diagnosing the issue and performing necessary repairs. They use their knowledge and expertise to identify the root cause of the problem and determine the appropriate repair procedures. They may replace damaged components, adjust settings, or recalibrate sensors to restore the equipment to working order.

3. Installation and Commissioning

Hoist Mechanics are involved in the installation and commissioning of new hoists and cranes. They ensure that the equipment is properly assembled, aligned, and calibrated according to specifications. They also conduct thorough testing to verify that the equipment is functioning safely and efficiently before it is put into operation.

4. Documentation and Record Keeping

Hoist Mechanics maintain detailed records of all inspections, repairs, and maintenance work performed on hoists and cranes. This documentation is essential for tracking the equipment’s history, identifying trends, and ensuring compliance with safety regulations. They may also use computerized systems to manage work orders and track maintenance schedules.

Interview Tips

Preparing for a Hoist Mechanic interview requires a combination of technical knowledge and effective communication skills. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Before the interview, take the time to learn about the company you are applying to. Research their website, industry news, and social media pages to gain insights into their business operations, values, and recent developments. This will demonstrate your interest in the company and help you tailor your answers to align with their needs.

For example, if the company specializes in heavy machinery manufacturing, highlight your experience in repairing and maintaining large-scale industrial equipment.

2. Review Technical Concepts

Hoist Mechanics are expected to have a strong understanding of mechanical and electrical systems. Review basic concepts in mechanics, electricity, hydraulics, and rigging. Study the principles of hoist and crane operation, including load capacities, safety devices, and control systems.

For instance, be prepared to discuss the importance of load distribution and the factors that affect the stability of a crane.

3. Practice Troubleshooting Scenarios

During the interview, you may be asked about your troubleshooting skills. Practice common troubleshooting scenarios that you may encounter when repairing hoists or cranes. Think about the steps you would take to identify the problem, isolate the cause, and determine the appropriate repair solution.

For example, you could describe a situation where you diagnosed an electrical fault in a hoist and replaced a faulty component to resolve the issue.

4. Highlight Safety Knowledge and Compliance

Safety is paramount in the hoisting industry. Emphasize your knowledge of relevant safety regulations and standards, such as OSHA and ASME guidelines. Explain how you prioritize safety in your work and ensure that hoists and cranes are operated safely.

For instance, share an example where you implemented a new safety protocol to reduce the risk of accidents at a previous workplace.

5. Showcase Your Communication and Teamwork Skills

Hoist Mechanics often work in teams and interact with operators, engineers, and maintenance personnel. Demonstrate your ability to communicate effectively, both verbally and in writing. Highlight your teamwork skills and ability to collaborate with others to achieve common goals.

For example, describe a situation where you worked with a team to diagnose a complex problem with a crane and successfully resolved it.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hoist Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.