Are you gearing up for an interview for a Hoist Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hoist Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

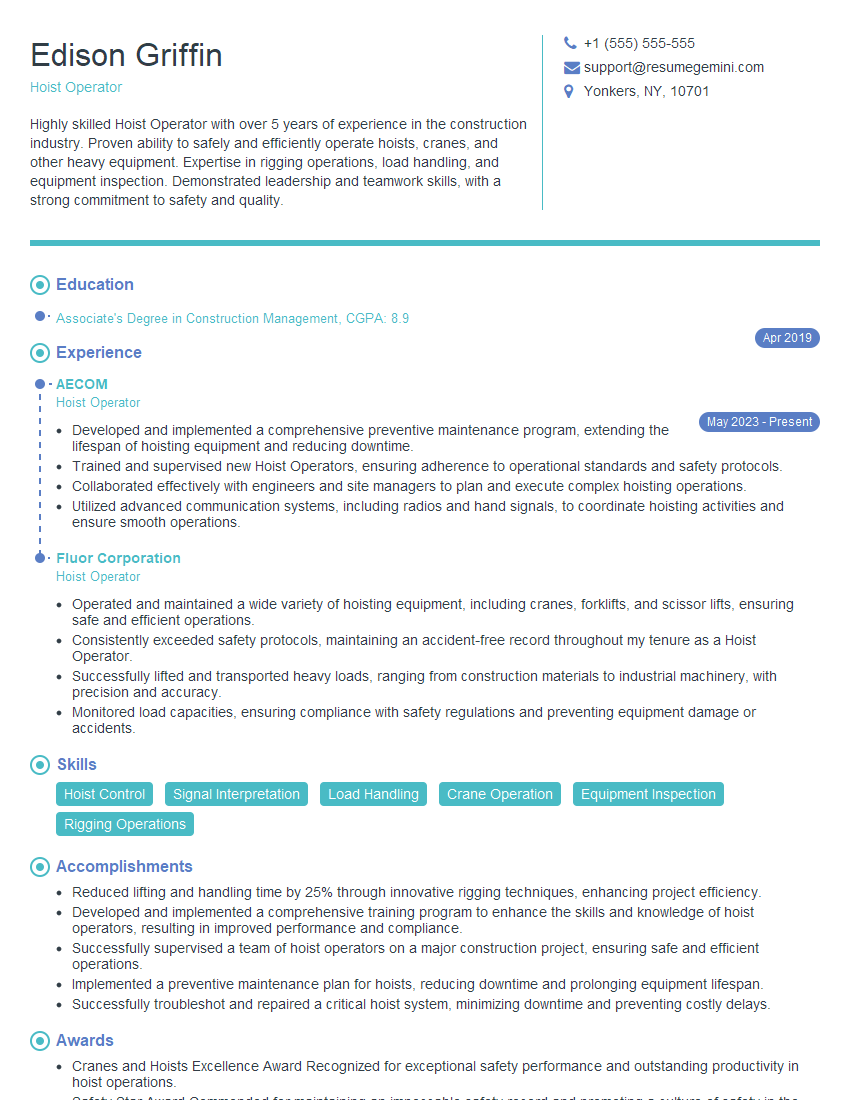

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hoist Operator

1. What are the different types of hoists and their uses?

- Chain hoists: These hoists use a chain to lift and lower loads. They are typically used in industrial settings, such as factories and warehouses.

- Wire rope hoists: These hoists use a wire rope to lift and lower loads. They are typically used in construction and mining applications.

- Air hoists: These hoists use compressed air to lift and lower loads. They are typically used in hazardous environments, such as chemical plants and refineries.

- Electric hoists: These hoists use an electric motor to lift and lower loads. They are typically used in industrial and commercial settings.

2. What are the safety precautions that should be taken when operating a hoist?

- Always inspect the hoist and load before operating it.

- Never overload the hoist.

- Never operate the hoist under the influence of drugs or alcohol.

- Always wear appropriate safety gear, such as gloves and a hard hat.

- Never leave the hoist unattended while it is in operation.

3. What are the different types of loads that can be lifted by a hoist?

- Solid objects, such as crates, boxes, and machinery.

- Liquids, such as water, oil, and chemicals.

- Gases, such as propane and natural gas.

- People, such as construction workers and window washers.

4. What are the different types of rigging that can be used with a hoist?

- Slings: Slings are used to attach the load to the hoist. They can be made of a variety of materials, such as nylon, wire rope, and chain.

- Hooks: Hooks are used to attach slings to the hoist. They can be made of a variety of materials, such as steel, aluminum, and titanium.

- Shackles: Shackles are used to connect slings and hooks together. They can be made of a variety of materials, such as steel, aluminum, and bronze.

- Eyebolts: Eyebolts are used to provide a secure anchor point for slings and hooks. They can be made of a variety of materials, such as steel, aluminum, and stainless steel.

5. What are the different types of inspections that should be performed on a hoist?

- Daily inspections: Daily inspections should be performed before each use of the hoist. They should include a visual inspection of the hoist and load, as well as a functional test of the hoist.

- Weekly inspections: Weekly inspections should be performed in addition to daily inspections. They should include a more thorough inspection of the hoist and load, as well as a load test of the hoist.

- Monthly inspections: Monthly inspections should be performed in addition to daily and weekly inspections. They should include a detailed inspection of the hoist and load, as well as a load test of the hoist.

- Annual inspections: Annual inspections should be performed in addition to daily, weekly, and monthly inspections. They should include a comprehensive inspection of the hoist and load, as well as a load test of the hoist.

6. What are the different types of maintenance that should be performed on a hoist?

- Preventive maintenance: Preventive maintenance is performed on a regular basis to prevent breakdowns and extend the life of the hoist. It includes tasks such as lubrication, cleaning, and adjustments.

- Corrective maintenance: Corrective maintenance is performed to repair breakdowns and restore the hoist to working order. It includes tasks such as replacing parts, welding, and machining.

7. What are the different types of training that should be provided to hoist operators?

- Basic training: Basic training should cover the fundamentals of hoist operation, including safety procedures, inspection procedures, and maintenance procedures.

- Advanced training: Advanced training should cover more specialized topics, such as load handling techniques, rigging techniques, and troubleshooting procedures.

8. What are the different types of certifications that are available for hoist operators?

- National Commission for the Certification of Crane Operators (NCCCO): NCCCO offers a variety of certifications for hoist operators, including the CCO (Crane Operator Certification) and the RCCO (Rigging and Crane Operator Certification).

- American Society of Mechanical Engineers (ASME): ASME offers the QEI (Qualified Elevator Inspector) certification for hoist operators who inspect and maintain elevators.

- Occupational Safety and Health Administration (OSHA): OSHA offers the OHS (Occupational Health and Safety) certification for hoist operators who work in construction and other hazardous industries.

9. What are the different types of jobs that are available for hoist operators?

- Construction: Hoist operators are responsible for lifting and lowering materials and equipment on construction sites.

- Manufacturing: Hoist operators are responsible for lifting and lowering materials and products in manufacturing facilities.

- Mining: Hoist operators are responsible for lifting and lowering materials and equipment in mines.

- Warehousing: Hoist operators are responsible for lifting and lowering materials and products in warehouses.

- Transportation: Hoist operators are responsible for lifting and lowering materials and equipment on ships, trains, and airplanes.

10. What are the different types of skills that are required for hoist operators?

- Mechanical skills: Hoist operators must have a good understanding of mechanical systems, including hoists, rigging, and loads.

- Electrical skills: Hoist operators must have a basic understanding of electrical systems, including motors, controllers, and wiring.

- Hydraulic skills: Hoist operators must have a basic understanding of hydraulic systems, including pumps, valves, and cylinders.

- Welding skills: Hoist operators must have basic welding skills to repair and maintain hoists and rigging.

- Communication skills: Hoist operators must have good communication skills to interact with other workers, including supervisors, engineers, and maintenance personnel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hoist Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hoist Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hoist Operators are responsible for operating hoists, cranes, and other lifting equipment to move materials, equipment, and personnel. They typically work in industrial settings, such as construction sites, factories, and warehouses. Their primary duties include:

1. Operating hoists and cranes

Hoist Operators must be able to safely and efficiently operate hoists and cranes. This includes knowing how to load and unload materials, as well as how to move them safely and securely.

- Loading and unloading materials

- Moving materials safely and securely

2. Maintaining equipment

Hoist Operators are also responsible for maintaining their equipment. This includes performing regular inspections, making repairs, and lubricating the equipment as needed.

- Performing regular inspections

- Making repairs

- Lubricating the equipment

3. Inspecting loads

Before lifting a load, Hoist Operators must inspect it to ensure that it is safe to move. This includes checking the weight of the load, the condition of the load, and the rigging.

- Checking the weight of the load

- Checking the condition of the load

- Checking the rigging

4. Following safety procedures

Hoist Operators must always follow safety procedures when operating hoists and cranes. This includes wearing appropriate safety gear, using proper hand signals, and being aware of their surroundings.

- Wearing appropriate safety gear

- Using proper hand signals

- Being aware of their surroundings

Interview Tips

To ace an interview for a Hoist Operator position, it is important to be prepared. Here are a few tips:

1. Research the company and the position

Before the interview, research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing clothing that is too revealing or too casual.

- Wear clean, pressed clothes

- Wear shoes that are comfortable and appropriate for the workplace

- Avoid wearing clothing that is too revealing or too casual

4. Be confident and positive

Confidence is key in any interview. Believe in yourself and your abilities, and let the interviewer know that you are enthusiastic about the position. Maintain eye contact, smile, and speak clearly and confidently. A positive attitude will go a long way in making a good impression.

- Believe in yourself and your abilities

- Let the interviewer know that you are enthusiastic about the position

- Maintain eye contact, smile, and speak clearly and confidently

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hoist Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.