Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hollow Handle Bench Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

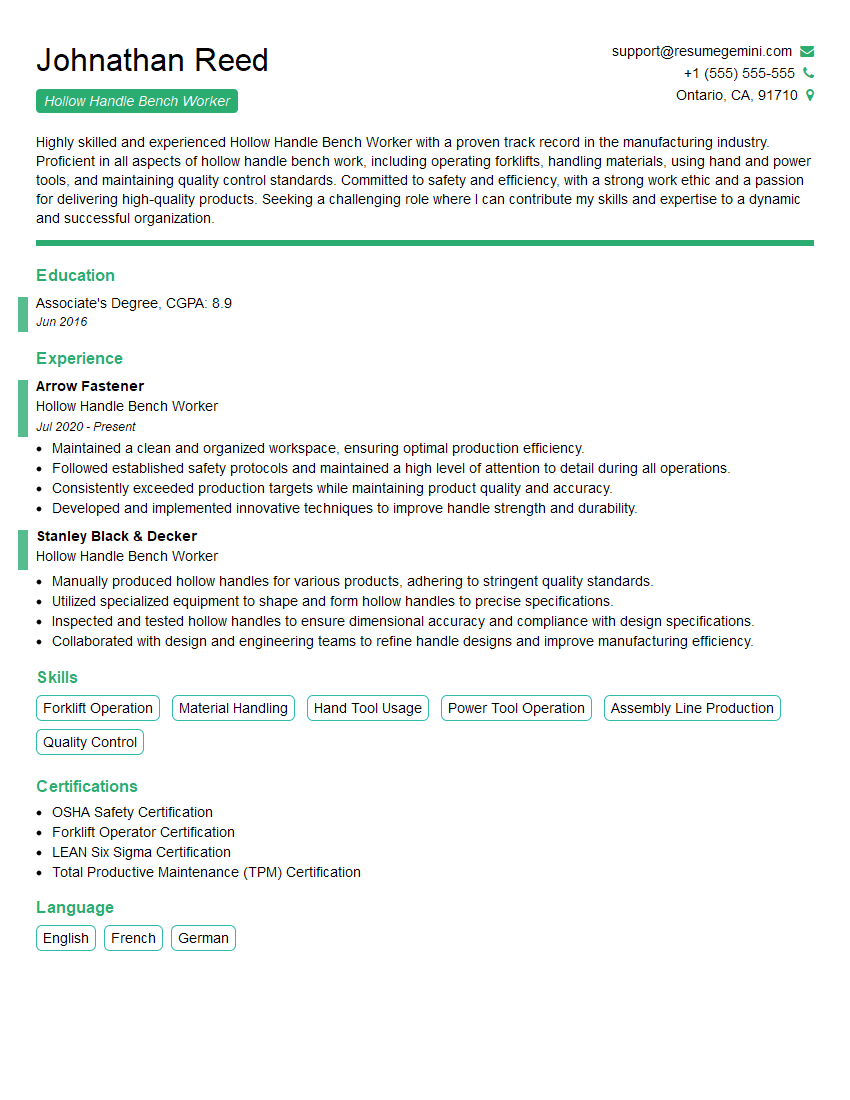

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hollow Handle Bench Worker

1. What are the key responsibilities of a Hollow Handle Bench Worker?

- Prepare and assemble hollow handles for various tools and equipment.

- Cut and shape raw wood or plastic materials to create handles.

- Drill holes, sand, and finish handles according to specifications.

- Install and align handle components, such as grips and ferrules.

- Inspect finished handles for quality and adherence to standards.

2. What are the different types of hollow handle materials and their properties?

Wood

- Lightweight and easy to work with.

- Durable and resistant to wear and tear.

- Available in various species with different grain patterns and colors.

Plastic

- Synthetic material that is lightweight and durable.

- Resistant to chemicals and moisture.

- Available in a wide range of colors and finishes.

3. What are the safety precautions that must be taken when working with hollow handle materials?

- Wear appropriate safety gear such as gloves, eye protection, and earplugs.

- Use sharp cutting tools carefully and follow proper cutting techniques.

- Ensure that the work area is well-ventilated and free of dust and debris.

- Handle chemicals and adhesives with care and follow instructions for proper disposal.

- Report any accidents or injuries promptly and seek medical attention if necessary.

4. How do you measure and ensure the accuracy of hollow handle dimensions?

- Use precision measuring tools such as calipers, rulers, and gauges.

- Follow engineering drawings and specifications carefully.

- Check measurements at multiple points to ensure accuracy.

- Use jigs or fixtures to maintain consistency and precision.

- Inspect finished handles thoroughly before assembly to identify any errors.

5. What are the common defects that can occur in hollow handle production and how do you prevent them?

- Cracks or splits: Use proper drying techniques and prevent excessive stress during assembly.

- Uneven or misaligned components: Ensure proper alignment of parts and use precision jigs or fixtures.

- Defective materials: Inspect materials thoroughly before use and follow guidelines for proper storage.

- Insufficient glue bond: Use appropriate adhesives and apply them evenly, allowing sufficient curing time.

- Poor surface finish: Use high-quality finishing materials and follow recommended sanding and polishing techniques.

6. How do you maintain and calibrate the machinery and tools used in hollow handle production?

- Follow manufacturer’s instructions for maintenance and calibration.

- Inspect machines and tools regularly for wear or damage.

- Clean and lubricate machines as necessary.

- Use calibration standards and devices to ensure accuracy.

- Keep maintenance records and report any issues to supervisors.

7. What are the quality control measures used in hollow handle production?

- Regular inspection of raw materials and finished products.

- Use of gauges and measuring devices to ensure dimensional accuracy.

- Testing for strength and durability.

- Visual inspection for defects and deviations from specifications.

- Implementation of quality control procedures and documentation.

8. How do you ensure efficient and lean production of hollow handles?

- Streamline production processes and eliminate bottlenecks.

- Optimize layout and workflow for maximum efficiency.

- Use jigs and fixtures to reduce setup times and improve accuracy.

- Implement standardized work instructions and training.

- Monitor production and identify areas for improvement.

9. What is the importance of teamwork and communication in hollow handle production?

- Facilitates efficient problem-solving and decision-making.

- Improves coordination between different production units.

- Enhances employee engagement and job satisfaction.

- Reduces errors and improves product quality.

- Promotes a positive and collaborative work environment.

10. How do you stay updated with the latest developments and best practices in hollow handle production?

- Attend industry conferences and exhibitions.

- Read trade publications and research papers.

- Consult with experts and professionals in the field.

- Participate in online forums and discussions.

- Experiment with new techniques and materials to improve production efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hollow Handle Bench Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hollow Handle Bench Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hollow Handle Bench Workers are responsible for a variety of tasks in the production of hollow handles. These tasks include:

1. Forming the Handle

Using a variety of tools and equipment, Bench Workers form the handle from raw materials.

- Inspecting raw materials to ensure they meet specifications

- Operating machines to bend, shape, and cut materials

- Assembling components to create the handle

2. Finishing the Handle

Once the handle is formed, Bench Workers finish it to prepare it for use.

- Sanding and smoothing the handle to remove any rough edges

- Applying a finish to the handle to protect it from wear and tear

- Inspecting the finished handle to ensure it meets quality standards

3. Packaging the Handle

Once the handle is finished, Bench Workers package it for shipment.

- Wrapping the handle in protective material

- Boxing or crating the handle for shipment

- Labeling the handle with the appropriate shipping information

4. Maintaining the Work Area

Bench Workers are also responsible for maintaining their work area.

- Keeping the work area clean and organized

- Inspecting equipment regularly and making necessary repairs

- Following safety protocols to prevent accidents

Interview Tips

To ace an interview for a Hollow Handle Bench Worker position, follow these tips:

1. Research the Company and the Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position.

- Visit the company’s website to learn about its history, products, and services.

- Read online reviews of the company to get an idea of its reputation.

- Look up the job description for the position you are applying for to identify the key responsibilities and qualifications.

2. Prepare Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience in working with hollow handles?

Take some time to prepare answers to these questions in advance. Be clear, concise, and specific in your answers, and be sure to highlight your skills and experience that are most relevant to the position.

3. Be Enthusiastic and Professional

First impressions matter, so it is important to be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and be polite and respectful to the interviewer.

- Make eye contact with the interviewer and smile.

- Speak clearly and confidently.

- Be prepared to ask questions about the company and the position.

4. Follow Up

After the interview, send a thank-you note to the interviewer. This is a great way to express your appreciation for their time and to reiterate your interest in the position. You can also use this opportunity to clarify any questions you may have about the position or the company.

- Keep your thank-you note brief and to the point.

- Thank the interviewer for their time and consideration.

- Reiterate your interest in the position.

- Ask any questions you may have.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hollow Handle Bench Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hollow Handle Bench Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.