Are you gearing up for a career in Hollow Ware Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Hollow Ware Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

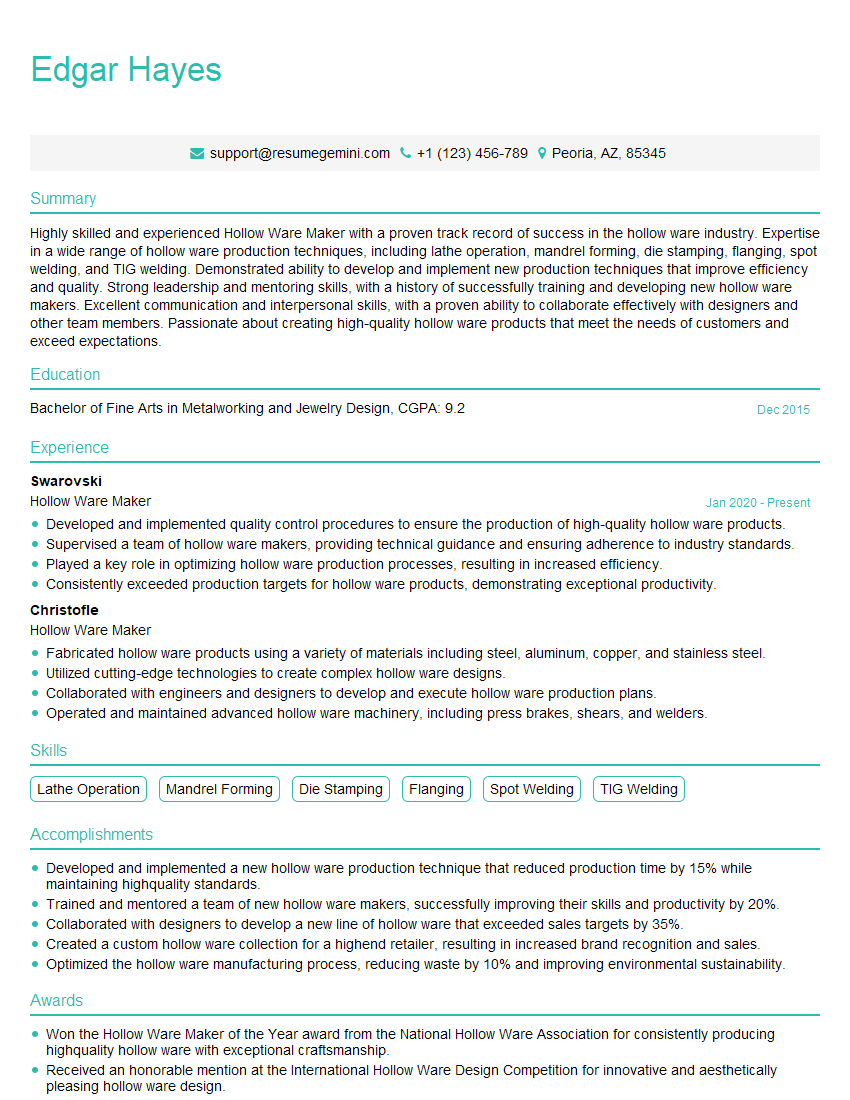

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hollow Ware Maker

1. What is your understanding of the Hollow Ware Making process?

The Hollow Ware Making process involves creating hollow metalware items, such as pots, pans, and bowls. It requires a combination of metalworking skills, such as cutting, shaping, and welding, and an understanding of metal properties and fabrication techniques. It typically involves:

- Pattern making to create a mold or template for the desired shape.

- Cutting and shaping the metal using tools such as shears, brakes, and rollers.

- Joining the metal pieces using welding, soldering, or brazing techniques.

- Finishing the item by polishing, buffing, or applying a coating.

2. Describe the different types of materials used in Hollow Ware Making.

Metals

- Stainless steel: Durable, corrosion-resistant, and easy to clean.

- Aluminum: Lightweight, corrosion-resistant, and good heat conductor.

- Copper: Excellent heat conductor, but prone to tarnishing.

- Cast iron: Durable, retains heat well, but heavy and prone to rust.

Non-Metals

- Plastic: Lightweight, durable, and available in various colors.

- Glass: Heat-resistant, but fragile and can shatter.

- Ceramics: Durable, heat-resistant, but heavy and can chip.

3. Explain the safety precautions that should be taken while working with hollow ware making machinery.

- Wear appropriate safety gear, including gloves, safety glasses, and a mask.

- Inspect machinery regularly and ensure it is in good working order.

- Operate machinery only if trained and authorized.

- Keep the work area clean and free of debris.

- Follow lockout/tagout procedures when servicing or repairing machinery.

4. What are the key factors to consider when designing a hollow ware product?

- Function: The intended use of the product and its required features.

- Materials: Selecting materials that meet the desired properties, such as durability, heat resistance, and aesthetics.

- Shape: Designing a shape that is both functional and visually appealing.

- Size: Determining the appropriate size for the intended use and target market.

- Cost: Considering the materials, manufacturing process, and labor involved to ensure affordability.

5. Describe the process of creating a prototype for a hollow ware product.

- Develop a design based on sketches, drawings, or computer-aided design (CAD) software.

- Select materials and determine the fabrication techniques to be used.

- Create a physical prototype using techniques such as metalworking, molding, or 3D printing.

- Test the prototype to assess its functionality, durability, and aesthetics.

- Refine the design based on testing results and user feedback.

6. What are the different methods used to finish hollow ware products?

- Polishing: Smoothing and brightening the surface using abrasive materials.

- Buffing: Bringing out the shine of the metal using polishing wheels.

- Electroplating: Coating the surface with a thin layer of metal, such as chrome or nickel, to enhance durability and aesthetics.

- Anodizing: Creating a protective and decorative oxide layer on aluminum surfaces.

- Powder coating: Applying a durable and corrosion-resistant coating using electrostatically charged powder.

7. Explain the importance of quality control in Hollow Ware Making.

- Ensures the products meet the desired specifications and standards.

- Detects and prevents defects, minimizing customer complaints and product recalls.

- Maintains product consistency and reliability, enhancing brand reputation.

- Optimizes production processes, reducing waste and improving efficiency.

- Protects consumers from faulty or unsafe products.

8. Describe your experience with using computer-aided design (CAD) software in Hollow Ware Making.

- Proficient in software such as SolidWorks, AutoCAD, or Blender.

- Ability to create 3D models and technical drawings for product design.

- Experience in using CAD for prototyping, simulation, and production planning.

- Understanding of CAD principles, including geometry, dimensions, and tolerances.

- Ability to translate design concepts into precise digital models.

9. Explain how you stay updated on the latest trends and advancements in Hollow Ware Making.

- Attend industry events, conferences, and workshops.

- Read trade publications, technical journals, and online resources.

- Network with other professionals in the field.

- Experiment with new techniques and materials.

- Engage in continuing education courses or certifications.

10. Describe a challenging Hollow Ware Making project you worked on and how you overcame the obstacles.

In a recent project, I encountered challenges in creating a complex hollow ware design with intricate curves and thin walls. To overcome these obstacles, I:

- Utilized advanced forming techniques, such as roll forming and hydroforming, to achieve the desired shapes.

- Developed custom jigs and fixtures to ensure precision and consistency.

- Collaborated with engineers to optimize the design for manufacturability.

- Implemented rigorous quality control measures to monitor the production process.

- Ultimately, we successfully produced the hollow ware item to the client’s exact specifications, demonstrating our ability to handle complex projects and deliver exceptional results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hollow Ware Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hollow Ware Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Hollow Ware Maker, you will be responsible for utilizing your exceptional skills in the crafting of hollow ware items, from concept development to completion. Your responsibilities will encompass:

1. Design and Development

Collaborate with designers and product development teams to create innovative and functional hollow ware designs.

- Sketch and develop design concepts, considering both aesthetic appeal and practicality.

- Create prototypes and test designs to ensure optimal functionality and durability.

2. Manufacturing Expertise

Demonstrate proficiency in various manufacturing techniques to produce high-quality hollow ware items.

- Utilize specialized tools and equipment, such as lathes, mills, and welding machines, to shape and assemble metal components.

- Apply specialized techniques like spinning, raising, and forming to create intricate and seamless hollow ware pieces.

3. Quality Control and Finishing

Ensure the highest quality standards for all produced hollow ware items.

- Inspect finished products for defects and adherence to design specifications.

- Perform finishing processes, such as polishing, plating, and lacquering, to enhance the aesthetic and protective qualities of the items.

4. Research and Innovation

Stay abreast of industry trends and advancements in hollow ware manufacturing.

- Explore new materials, techniques, and technologies to improve efficiency and enhance product quality.

- Collaborate with research and development teams to develop innovative manufacturing processes.

Interview Tips

To ace your Hollow Ware Maker interview, consider the following tips and hacks:

1. Research the Company and Role

Demonstrate your interest and preparation by thoroughly researching the company, its values, and the specific role you’re applying for. This shows the interviewer that you’re genuinely interested in the opportunity and have taken the time to understand the company’s culture and goals.

- Visit the company’s website, LinkedIn page, and Glassdoor profile to learn about their mission, products/services, and employee reviews.

- Review the job description carefully and identify the key responsibilities, qualifications, and skills required for the role.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the key responsibilities of the Hollow Ware Maker role. Showcase your expertise in design, manufacturing, and quality control.

- Quantify your accomplishments whenever possible using specific metrics. For example, instead of saying “I have experience in hollow ware manufacturing,” you could say, “I have manufactured over 500 high-quality hollow ware items using various techniques.”

- Prepare examples of your best work and be ready to discuss your design inspirations, challenges you’ve overcome, and lessons you’ve learned.

3. Demonstrate Your Passion

Convey your genuine interest and passion for hollow ware making during the interview. This enthusiasm will set you apart from other candidates and demonstrate your commitment to the craft.

- Share your personal projects or hobbies related to hollow ware or metalworking, if any.

- Express your admiration for the company’s hollow ware products and how you’re eager to contribute your skills to their team.

4. Ask Thoughtful Questions

At the end of the interview, prepare a few thoughtful questions to ask the interviewer. This shows that you’re engaged and interested in learning more about the role and company.

- Ask about the company’s future plans for hollow ware production.

- Inquire about opportunities for professional development and growth within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hollow Ware Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.