Feeling lost in a sea of interview questions? Landed that dream interview for Hoop Coiler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hoop Coiler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

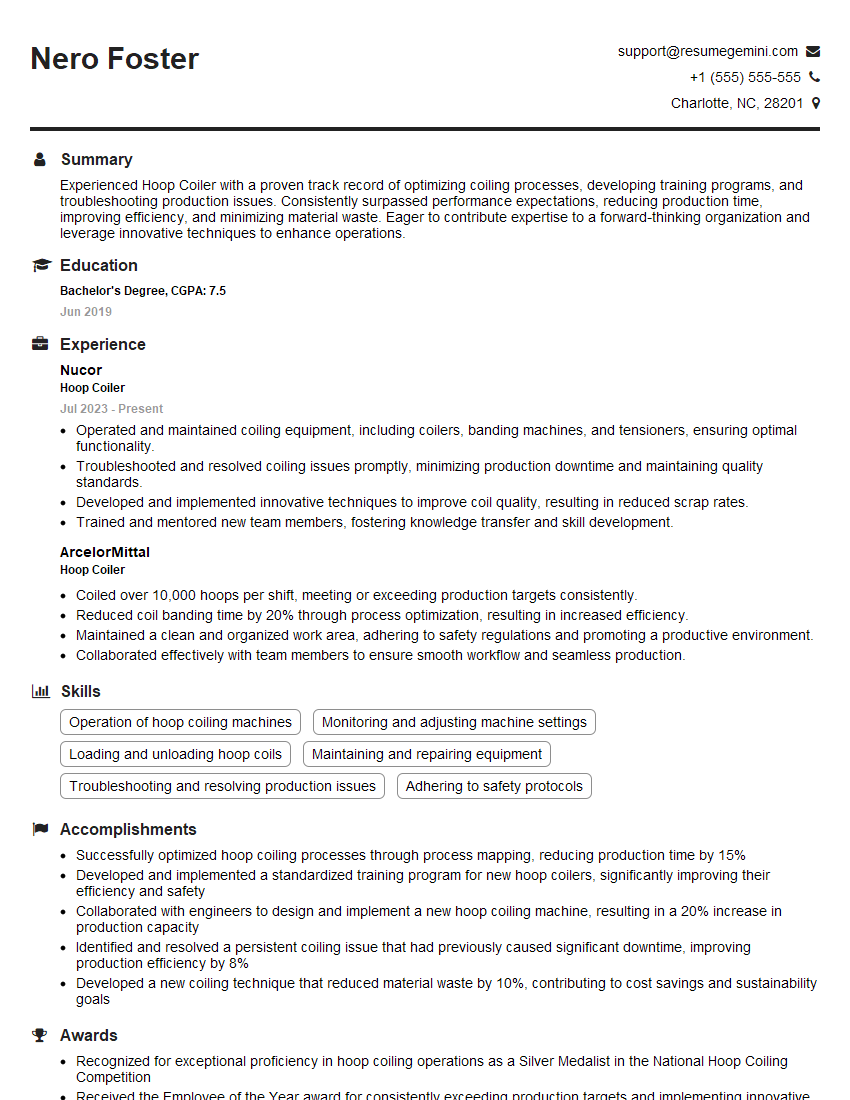

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hoop Coiler

1. What are the key responsibilities of a Hoop Coiler?

- Loading and unloading reels of material onto the coiling machine.

- Monitoring the coiling process to ensure that the hoops are produced to the correct specifications.

- Maintaining and troubleshooting the coiling machine.

- Inspecting the finished hoops for defects.

- Following all safety procedures.

2. What experience do you have in operating a hoop coiling machine?

Experience in hoop coiling

- I have 5 years of experience operating a hoop coiling machine in a manufacturing environment.

- I am proficient in all aspects of the coiling process, from loading and unloading the reels to monitoring the machine and inspecting the finished hoops.

Knowledge in hoop coiling machine

- I have a thorough understanding of the hoop coiling machine, including its components, operation, and maintenance procedures.

- I am also familiar with the different types of hoops that can be produced on the machine, as well as the various materials that can be used.

3. What are some of the challenges you have faced in your previous role as a Hoop Coiler?

- One of the challenges I faced in my previous role was meeting the high production demands while maintaining the quality of the hoops.

- Another challenge was working with a variety of materials, each with its own unique properties and requirements.

4. How do you ensure that the hoops you produce meet the required specifications?

- I follow a strict set of procedures to ensure that the hoops meet the required specifications.

- These procedures include checking the material, setting up the machine, and monitoring the coiling process.

- I also perform regular inspections of the finished hoops to ensure that they are free of defects.

5. What are your strengths and weaknesses as a Hoop Coiler?

Strengths

- My strengths include my attention to detail, my ability to work independently, and my commitment to quality.

- I am also a team player and I am always willing to help out my colleagues.

Weaknesses

- One of my weaknesses is that I can be a bit of a perfectionist at times.

- I also have a tendency to be hard on myself when I make mistakes.

6. What are your career goals as a Hoop Coiler?

- My career goal is to become a lead Hoop Coiler.

- I would like to continue to develop my skills and knowledge in the field of hoop coiling, and I am confident that I have the potential to become a valuable asset to any company.

7. What are the different types of hoops that can be produced on a hoop coiling machine?

- The different types of hoops that can be produced on a hoop coiling machine include round hoops, oval hoops, and square hoops.

- Round hoops are the most common type of hoop, and they are used in a variety of applications, such as packaging, construction, and agriculture.

- Oval hoops are used in applications where a more oval shape is required, such as in the manufacture of barrels and drums.

- Square hoops are used in applications where a square shape is required, such as in the manufacture of window frames and doors.

8. What are the different materials that can be used to make hoops?

- The different materials that can be used to make hoops include steel, aluminum, and plastic.

- Steel hoops are the most common type of hoop, and they are used in a variety of applications because of their strength and durability.

- Aluminum hoops are lighter than steel hoops, and they are often used in applications where weight is a factor, such as in the aerospace industry.

- Plastic hoops are the most flexible type of hoop, and they are often used in applications where flexibility is required, such as in the packaging industry.

9. What are some of the common problems that can occur during the hoop coiling process?

- Some of the common problems that can occur during the hoop coiling process include:

- Material tangling

- Machine jams

- Hoop defects

- These problems can be caused by a variety of factors, such as improper machine setup, worn or damaged parts, and operator error.

10. What are some of the safety precautions that should be taken when operating a hoop coiling machine?

- Some of the safety precautions that should be taken when operating a hoop coiling machine include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Keeping the work area clean and free of debris.

- Being aware of the location of all controls and emergency stops.

- Following all manufacturer’s instructions for safe operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hoop Coiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hoop Coiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hoop Coilers are responsible for the production and maintenance of steel hoops and are essential to the smooth operation of the mill. Their primary duties involve setting up and operating the Hoop Coiler machine and related equipment, monitoring production, and performing preventative maintenance tasks.

1. Machine Operation and Setup

Hoop Coilers are proficient in operating and setting up the Hoop Coiler machine. They ensure that the machine is in optimal working condition, calibrating and adjusting settings as needed. Additionally, they monitor the machine’s performance and troubleshoot any issues that may arise.

- Operate the Hoop Coiler machine to produce steel hoops according to specifications.

- Set up the machine, including adjusting tension, speed, and other parameters.

2. Production Monitoring and Quality Control

Hoop Coilers are responsible for monitoring the production process and ensuring that the hoops meet the required quality standards. They visually inspect the hoops for defects, such as cracks, breaks, or improper dimensions, and take corrective actions when necessary. Additionally, they maintain records of production data, monitor scrap rates, and participate in quality improvement initiatives.

- Monitor the production process to ensure that hoops are being produced according to specifications.

- Inspect hoops for defects and take corrective action as necessary.

- Maintain production records and monitor scrap rates.

3. Maintenance and Troubleshooting

Hoop Coilers perform preventative maintenance tasks on the Hoop Coiler machine and related equipment to ensure reliable operation. They clean, lubricate, and adjust components as necessary, and troubleshoot and repair any equipment malfunctions. Additionally, they maintain an inventory of spare parts and consumables to minimize downtime.

- Perform preventative maintenance tasks on the Hoop Coiler machine and related equipment.

- Troubleshoot and repair equipment malfunctions.

- Maintain an inventory of spare parts and consumables.

4. Safety and Compliance

Hoop Coilers are committed to maintaining a safe work environment and adhering to all safety regulations. They follow established safety protocols, use personal protective equipment (PPE), and participate in safety training programs. Additionally, they are familiar with environmental regulations and ensure that their work complies with these standards.

- Follow established safety protocols and use PPE.

- Participate in safety training programs.

- Ensure that their work complies with environmental regulations.

Interview Tips

Preparing for an interview for a Hoop Coiler position requires thorough knowledge of the job responsibilities and industry-specific skills. Here are some tips to help you ace your interview and showcase your qualifications:

1. Research the Company and Position

Before the interview, take the time to research the company, its products, and its values. Familiarize yourself with the specific role and its responsibilities. This knowledge will enable you to tailor your answers and demonstrate your understanding of the company and the position.

- Visit the company’s website and social media platforms to learn about its culture, mission, and recent developments.

- Review the job description carefully and identify the key skills and qualifications required for the role.

2. Highlight Relevant Skills and Experience

During the interview, focus on highlighting your relevant skills and experience that align with the job requirements. Provide specific examples of your work that demonstrate your abilities in machine operation, production monitoring, maintenance, and safety. Use the STAR method (Situation, Task, Action, Result) to structure your answers and convey your impact.

- Quantify your accomplishments whenever possible to provide tangible evidence of your contributions.

- Be prepared to discuss your experience with different types of Hoop Coiler machines and equipment.

3. Emphasize Safety and Quality Control

Hoop Coilers play a crucial role in ensuring safety and maintaining product quality. In your interview, emphasize your commitment to safety and your understanding of quality control procedures. Highlight your experience in following safety protocols, using PPE, and participating in safety training programs.

- Share examples of how you have identified and mitigated potential hazards in the workplace.

- Describe your experience in conducting quality inspections and maintaining production records.

4. Prepare Questions to Ask

At the end of the interview, be prepared to ask thoughtful questions that show your interest in the company and the position. Asking intelligent questions can demonstrate your enthusiasm and engagement. Consider questions about the company’s growth plans, industry trends, or specific projects related to the role.

- Avoid asking questions that are easily answered by referring to the company’s website or job description.

- Prepare questions that are specific to the company and the position to demonstrate your interest in the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hoop Coiler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!