Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Hoop Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Hoop Machine Operator so you can tailor your answers to impress potential employers.

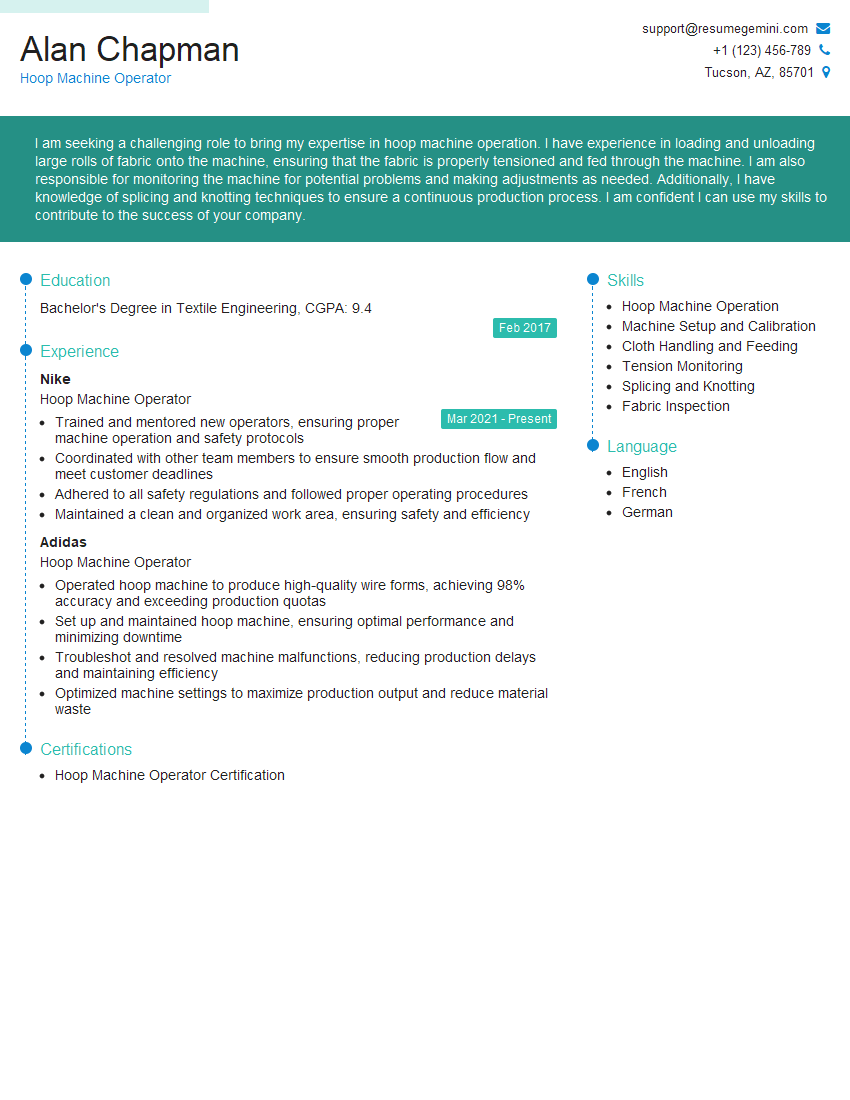

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hoop Machine Operator

1. What are the key responsibilities of a Hoop Machine Operator?

As a Hoop Machine Operator, my primary responsibilities encompass:

- Operating and maintaining hoop machines to produce seamless hoops

- Setting up and adjusting machine parameters, such as temperature, speed, and tension

- Loading and unloading hoops into the machine

- Monitoring the production process and making adjustments as needed

- Inspecting hoops for defects and ensuring quality standards are met

- Maintaining a clean and safe work environment

2. Describe the different types of hoop machines and their applications.

Manual Hoop Machines

- Require manual operation

- Typically used for small-scale production or specialized applications

Semi-Automatic Hoop Machines

- Combine manual and automated processes

- Offer higher production rates than manual machines

Fully Automatic Hoop Machines

- Completely automated, requiring minimal operator intervention

- Capable of high-volume production

3. How do you troubleshoot common problems with hoop machines?

Troubleshooting common problems with hoop machines involves a systematic approach:

- Identifying the symptoms of the problem

- Checking the machine’s settings and parameters

- Inspecting the machine’s components for any visible issues

- Referring to technical manuals or consulting with experienced operators

- Performing necessary adjustments or repairs to resolve the problem

4. What safety precautions should be taken when operating a hoop machine?

To ensure safety when operating a hoop machine, it is crucial to adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs

- Follow lockout/tagout procedures before performing any maintenance or repairs

- Keep the work area clean and free of debris

- Be aware of moving parts and potential hazards

- Never operate the machine under the influence of alcohol or drugs

5. How do you maintain hoop machines to ensure optimal performance?

Maintaining hoop machines for optimal performance requires a combination of routine tasks and preventive measures:

- Regularly cleaning and lubricating the machine’s components

- Inspecting and replacing worn or damaged parts as needed

- Calibrating the machine according to manufacturer’s specifications

- Performing scheduled maintenance and repairs to prevent breakdowns

- Following manufacturer’s recommendations for proper operation and maintenance of the equipment

6. What experience do you have with different types of hoop materials and their properties?

Throughout my experience as a Hoop Machine Operator, I have worked with various types of hoop materials, including:

- Steel: Durable, strong, suitable for heavy-duty applications

- Stainless Steel: Corrosion-resistant, ideal for food and beverage industries

- Aluminum: Lightweight, corrosion-resistant, used in aerospace and automotive applications

- Plastics: Different types of plastics offer unique properties, such as flexibility, impact resistance, and chemical resistance

- Composite Materials: Combinations of materials, providing a range of properties tailored to specific applications

7. How do you ensure the accuracy and consistency of hoop dimensions?

Ensuring the accuracy and consistency of hoop dimensions is crucial for product quality and functionality. I employ the following measures:

- Calibrating the hoop machine regularly using precision measuring instruments

- Monitoring the machine’s performance and making adjustments as needed

- Inspecting hoops throughout the production process to identify any deviations

- Using statistical process control (SPC) techniques to track and analyze hoop dimensions

- Following established quality control procedures and standards

8. What techniques do you use to minimize scrap and waste during hoop production?

Minimizing scrap and waste is essential for cost-effectiveness and sustainability. I utilize various techniques, such as:

- Optimizing machine settings to reduce material usage

- Reusing scrap material for non-critical applications

- Implementing preventive maintenance to minimize breakdowns and production losses

- Training operators on proper material handling and machine operation

- Working closely with quality control personnel to identify and address potential sources of defects

9. Describe your experience with automation and process improvement in hoop production.

In my previous role, I actively participated in automation and process improvement initiatives to enhance productivity:

- Implemented a new automated loading system, reducing labor costs and increasing production efficiency

- Developed a data-driven approach to identify bottlenecks and optimize production processes

- Trained operators on lean manufacturing principles to minimize waste and improve overall performance

- Collaborated with engineers to design and implement custom tooling for specific hoop applications

- Consistently sought opportunities to improve safety and ergonomics in the workplace

10. How do you stay up-to-date on the latest advancements in hoop machine technology?

To stay abreast of the latest advancements in hoop machine technology, I engage in ongoing professional development:

- Attending industry conferences and workshops

- Reading technical publications and industry journals

- Networking with other professionals in the field

- Participating in online forums and discussion groups

- Seeking opportunities to collaborate with equipment manufacturers and technology providers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hoop Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hoop Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hoop Machine Operator is responsible for operating a hoop machine to produce hoops for various purposes, such as barrels, drums, or other cylindrical containers. The key job responsibilities include:

1. Machine Operation

Operate the hoop machine to bend and shape metal or wooden strips into hoops of specified dimensions.

- Set up and adjust the machine according to production requirements.

- Monitor the machine’s operation to ensure proper functioning.

2. Material Handling

Load and unload metal or wooden strips onto the machine.

- Inspect materials for defects and ensure they meet specifications.

- Handle heavy materials safely and efficiently.

3. Quality Control

Inspect finished hoops for accuracy, dimensions, and quality.

- Identify and correct any defects in the hoops.

- Maintain records of production and quality control.

4. Maintenance

Perform basic maintenance on the hoop machine, such as cleaning, lubrication, and minor repairs.

- Report any major mechanical issues to supervisors.

- Participate in preventive maintenance programs.

Interview Tips

To ace an interview for a Hoop Machine Operator position, it is essential to prepare thoroughly and demonstrate your relevant skills. Here are some interview tips to help you succeed:

1. Research the Company and Industry

Learn about the company’s history, products or services, and industry trends. This will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

2. Highlight Your Relevant Skills

Emphasize your experience in operating hoop machines, handling materials, and maintaining equipment. Quantify your accomplishments whenever possible.

- Discuss specific examples of how you improved production efficiency or reduced defects.

- Mention any certifications or training programs you have completed.

3. Practice Common Interview Questions

Prepare for typical interview questions, such as “Tell me about yourself” or “Why are you interested in this position?”.

- Develop concise and engaging answers that showcase your skills and alignment with the job requirements.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

4. Ask Thoughtful Questions

Asking insightful questions shows your engagement and interest in the role and company. Prepare a few thoughtful questions about the position, the team you would be working with, or the company’s future plans.

- Avoid asking about salary or benefits at this stage.

- Show that you are curious and eager to learn more about the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hoop Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hoop Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.