Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hopper Feeder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

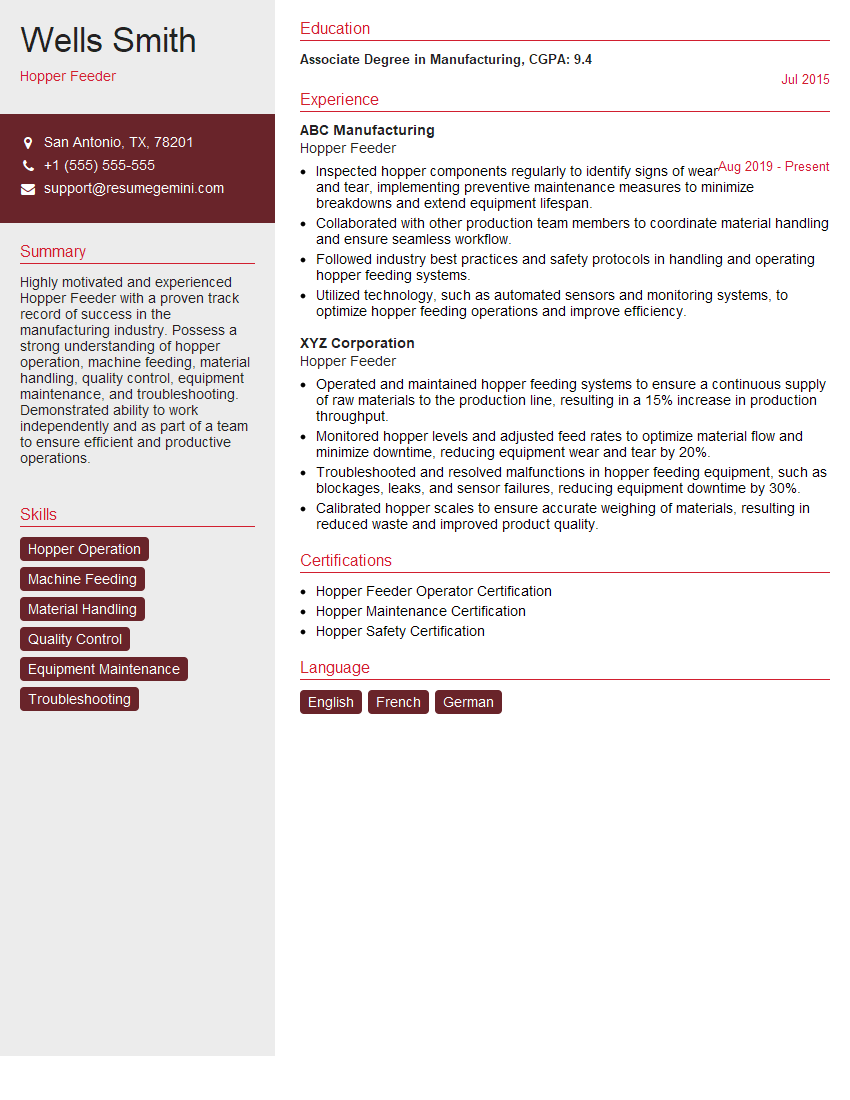

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hopper Feeder

1. Describe the types of hoppers you have worked with and their key features?

I have worked with various types of hoppers, including:

- Vibratory hoppers: These hoppers use vibrations to induce material flow. They are commonly used in bulk handling applications and have adjustable vibration frequency and amplitude to optimize material movement.

- Screw feeders: These hoppers utilize a screw conveyor to move material out of the hopper. They are suitable for handling fine powders and bridging materials, and the screw speed can be controlled to regulate material flow.

- Belt feeders: These hoppers employ a conveyor belt to transport material. They are often used in high-volume applications and can be equipped with sensors to monitor material flow rate.

- Surge hoppers: These hoppers are designed to accommodate temporary fluctuations in material flow. They act as a buffer between the hopper and downstream equipment, preventing disruptions in the process.

2. Discuss the factors that affect material flow in a hopper?

The following factors influence material flow in a hopper:

- Hopper geometry: The shape, size, and angle of the hopper walls impact material flow. A steep-angled hopper with smooth walls promotes flow, while a shallow-angled hopper with rough walls can hinder it.

- Material properties: The particle size, shape, and cohesion of the material affect its flowability. Fine, cohesive materials are more prone to bridging and flow problems.

- Hopper discharge: The size and type of discharge opening influence material flow. A large discharge opening allows for faster flow, while a small opening can restrict flow.

- Flow aids: Devices like vibrators, agitators, and baffles can improve material flow by reducing bridging and promoting uniformity.

3. Explain the role of hopper lining in preventing material buildup and wear?

Hopper lining plays a crucial role in preventing material buildup and wear:

- Non-stick properties: Hopper linings are often made of materials with low surface adhesion, such as Teflon or polyethylene. These materials reduce material buildup on hopper walls, ensuring smooth material flow.

- Wear resistance: Hoppers handling abrasive materials require linings with high wear resistance to prevent abrasion and damage to the hopper walls. Linings made of materials like stainless steel or ceramic provide excellent wear protection.

- Corrosion resistance: Hoppers used in corrosive environments need linings that can withstand chemical attack. Linings made of corrosion-resistant materials like fiberglass or rubber protect the hopper from deterioration.

4. Describe the maintenance procedures you have performed on hoppers?

Hopper maintenance involves several key procedures:

- Inspection: Regular inspection of the hopper for any signs of damage, wear, or buildup is crucial. This includes checking the hopper walls, discharge opening, and lining.

- Cleaning: Hoppers should be cleaned periodically to remove any accumulated material or debris. This can be done manually or through automated cleaning systems.

- Lining replacement: If the hopper lining becomes worn or damaged, it needs to be replaced to ensure proper material flow and prevent wear on the hopper walls.

- Calibration: Hoppers equipped with sensors or controllers should be calibrated regularly to ensure accurate material flow measurement and control.

5. Discuss the safety measures to be followed when working with hoppers?

Safety is paramount when working with hoppers:

- Lockout/Tagout: Isolate the hopper from power and other energy sources before performing any maintenance or repairs.

- Confined space entry: If the hopper is enclosed, ensure proper ventilation and follow confined space entry procedures before entering.

- Material hazards: Be aware of the potential hazards of the material being handled, such as toxicity, flammability, or explosiveness.

- Personal protective equipment: Wear appropriate personal protective equipment, such as gloves, eye protection, and hearing protection.

6. Explain the importance of hopper capacity in material handling systems?

Hopper capacity is crucial in material handling systems because it affects:

- Process continuity: A hopper with sufficient capacity ensures a continuous supply of material to the downstream process, minimizing interruptions and downtime.

- Material storage: Hoppers act as temporary storage for materials, allowing for surges in material flow or variations in demand.

- System efficiency: Optimizing hopper capacity can improve overall system efficiency by reducing the frequency of hopper refills and minimizing material handling costs.

7. Describe the process of selecting the appropriate hopper size for a particular material handling application?

Selecting the appropriate hopper size involves several steps:

- Material flow rate: Determine the maximum and average material flow rate required for the application.

- Material properties: Consider the flowability and bulk density of the material being handled, as these factors affect the hopper’s capacity.

- Hopper discharge type: The type of discharge opening and its dimensions influence the hopper’s discharge rate.

- Hopper geometry: The shape and angle of the hopper walls affect material flow and capacity.

8. Discuss the advantages and disadvantages of different hopper designs?

Different hopper designs offer varying advantages and disadvantages:

- Conical hoppers: Conical hoppers provide good material flow and are relatively easy to manufacture. However, they may have a smaller capacity compared to other designs.

- Pyramidal hoppers: Pyramidal hoppers offer increased capacity and can handle materials with poor flowability. However, they are more complex to manufacture.

- Rectangular hoppers: Rectangular hoppers are suitable for handling large volumes of material and can be easily integrated into modular systems. They may require additional flow aids to ensure proper material flow.

9. Explain the concept of hopper dead zones and how to minimize their impact?

Hopper dead zones are areas within the hopper where material does not flow due to frictional forces or bridging. To minimize their impact:

- Hopper geometry: Design the hopper with steep walls and a smooth surface to promote material flow.

- Flow aids: Utilize vibrators, agitators, or baffles to reduce friction and prevent material buildup.

- Hopper discharge: Ensure the discharge opening is large enough and positioned to minimize dead zones.

10. Describe the role of sensors in hopper monitoring and control systems?

Sensors play a crucial role in hopper monitoring and control systems:

- Level sensors: Monitor the material level inside the hopper and provide signals to control material flow.

- Flow sensors: Measure the material flow rate and provide feedback for flow rate control.

- Temperature sensors: Monitor the temperature inside the hopper, particularly important for materials that are sensitive to temperature changes.

- Vibration sensors: Detect vibrations in the hopper, which can indicate material bridging or flow problems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hopper Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hopper Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hopper Feeder is responsible for performing a range of tasks in the manufacturing environment, ensuring that the production line is running smoothly. This role plays a vital role in ensuring that the production process is efficient and effective.

1. Loading and Unloading Materials

Hopper Feeders are responsible for loading raw materials into hoppers and unloading finished products. They use a variety of equipment to perform these tasks, including forklifts, cranes, and conveyor belts.

- Operate forklifts and other equipment to move materials

- Load raw materials into hoppers and unload finished products

2. Monitoring Equipment

Hopper Feeders monitor equipment to ensure that it is operating properly. They inspect equipment for damage and make adjustments as needed. They also report any problems to their supervisor.

- Monitor equipment to ensure that it is operating properly

- Inspect equipment for damage and make adjustments as needed

- Report any problems to their supervisor

3. Cleaning and Maintaining Equipment

Hopper Feeders clean and maintain equipment to ensure that it is in good working condition. They perform routine maintenance tasks, such as cleaning, lubricating, and inspecting equipment. They also make repairs as needed.

- Clean and maintain equipment to ensure that it is in good working condition

- Perform routine maintenance tasks, such as cleaning, lubricating, and inspecting equipment

- Make repairs as needed

4. Maintaining a Safe Work Environment

Hopper Feeders follow safety procedures to ensure that they and their coworkers are safe. They wear appropriate safety gear and use equipment properly. They also report any safety hazards to their supervisor.

- Follow safety procedures to ensure that they and their coworkers are safe

- Wear appropriate safety gear and use equipment properly

- Report any safety hazards to their supervisor

Interview Tips

Preparing for a Hopper Feeder interview can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the Company

Before the interview, take some time to research the company. This will help you understand their culture, values, and what they’re looking for in a Hopper Feeder. You can find this information on the company’s website, social media pages, and Glassdoor.

- Visit the company’s website

- Read the company’s social media pages

- Check out the company on Glassdoor

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Practice answering common interview questions

- Deliver your answers confidently and concisely

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This doesn’t mean that you need to wear a suit and tie, but you should dress in clean, pressed clothes that are appropriate for the workplace.

- Dress professionally for your interview

- Wear clean, pressed clothes that are appropriate for the workplace

4. Be On Time

Punctuality is important in any job, but it’s especially important in a manufacturing environment. Make sure to arrive for your interview on time, or even a few minutes early.

- Arrive for your interview on time, or even a few minutes early

- Being punctual shows that you’re reliable and respectful of the interviewer’s time

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hopper Feeder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.