Feeling lost in a sea of interview questions? Landed that dream interview for Horizontal Boring Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Horizontal Boring Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

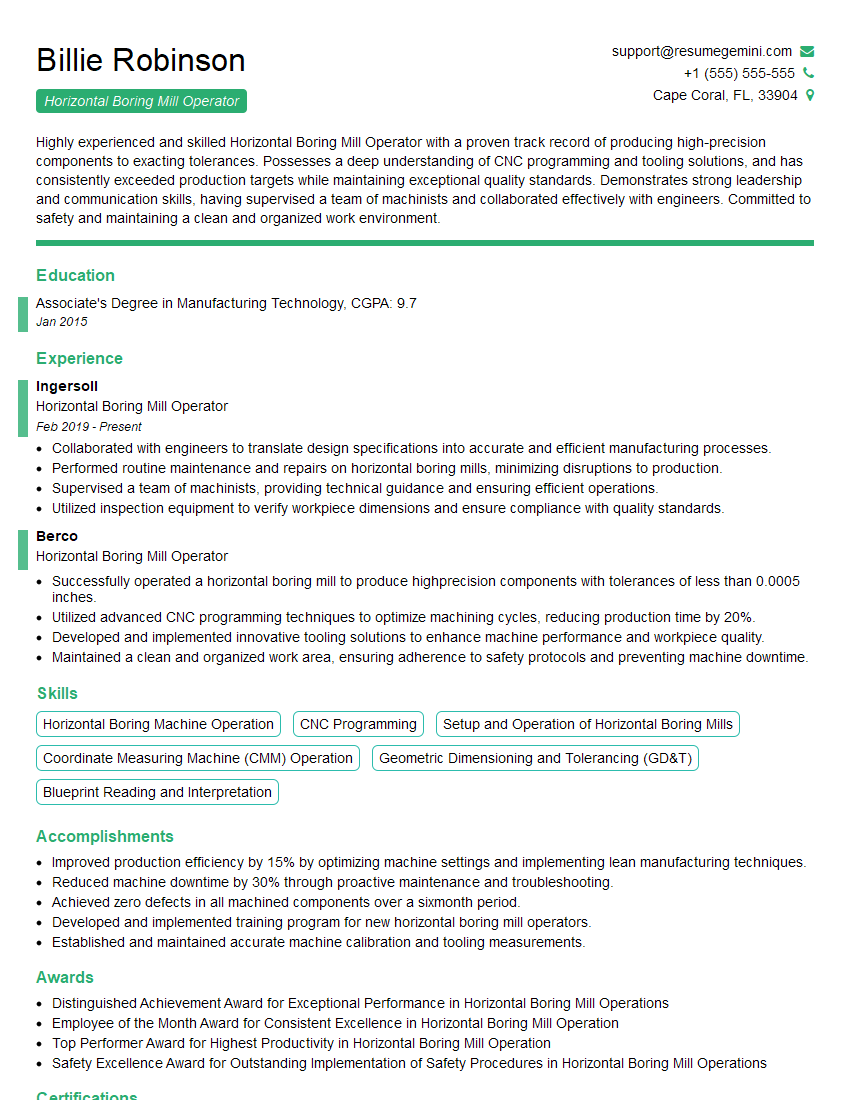

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Horizontal Boring Mill Operator

1. What are the key responsibilities of a Horizontal Boring Mill Operator?

- Operate, adjust, and maintain horizontal boring mills to bore, cut, and finish cylindrical and contoured surfaces of metal workpieces.

- Inspect and set up workpieces on rotary tables, chucks, and fixtures.

- Use precision measuring tools and gauges to ensure accuracy.

- Follow blueprints, diagrams, and work orders to perform specific operations.

- Monitor and adjust cutting tools, speeds, and feeds during operation.

2. Describe the different types of boring mills and their applications.

Horizontal Boring Mills

- Used for machining large and heavy workpieces.

- Have a horizontal spindle that can rotate and move along the X, Y, and Z axes.

Vertical Boring Mills

- Used for machining smaller and lighter workpieces.

- Have a vertical spindle that can rotate and move along the X and Y axes.

Floor-Type Boring Mills

- Used for machining very large and heavy workpieces.

- Have a spindle that is mounted on a base plate and can move in all three axes.

3. What are the important safety precautions to follow when operating a horizontal boring mill?

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and a hard hat.

- Ensure that the machine is properly grounded and the work area is well-lit.

- Inspect the machine before each use and report any problems to a supervisor.

- Keep hands and loose clothing away from moving parts.

- Never operate the machine while under the influence of drugs or alcohol.

4. How do you ensure the precision and accuracy of your work?

- Use precision measuring tools and gauges to calibrate the machine and measure workpieces.

- Follow blueprints, diagrams, and work orders accurately.

- Monitor and adjust cutting tools, speeds, and feeds during operation to maintain tolerances.

- Inspect finished workpieces for accuracy and correct any errors before proceeding to the next step.

5. What is the role of coolants in horizontal boring operations?

- Cool the cutting tool and workpiece to prevent overheating.

- Lubricate the cutting tool to reduce friction and wear.

- Remove chips and debris from the cutting area.

- Improve the surface finish of the workpiece.

6. Describe the different types of cutting tools used in horizontal boring mills.

- Boring bars

- Boring heads

- Fly cutters

- End mills

- Twist drills

7. What are the key factors to consider when selecting a cutting tool for a horizontal boring operation?

- The material of the workpiece.

- The type of operation (boring, facing, turning, etc.).

- The desired surface finish.

- The available horsepower and spindle speed of the machine.

8. How do you adjust the speed and feed rates of a horizontal boring mill?

- Use the machine’s control panel to set the desired speed and feed rates.

- Consider the material of the workpiece, the type of cutting tool, and the desired surface finish when selecting the speed and feed rates.

- Adjust the speed and feed rates during operation as needed to maintain optimal cutting conditions.

9. What is the purpose of using a rotary table on a horizontal boring mill?

- Allows for rotating the workpiece around a horizontal axis.

- Enables machining of cylindrical and contoured surfaces.

- Improves accuracy and efficiency by reducing the need for multiple setups.

10. Describe the different types of fixtures used in horizontal boring operations.

- Chucks

- Vises

- Clamps

- Angle plates

- Custom-designed fixtures

- The type of fixture used depends on the shape and size of the workpiece, the operation being performed, and the required accuracy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Horizontal Boring Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Horizontal Boring Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Horizontal Boring Mill Operators are responsible for operating and maintaining horizontal boring mills, which are used to create precise holes and other features in metal workpieces. Some of their key responsibilities include:

1. Setup and Operation

Setting up and operating the horizontal boring mill, including mounting the workpiece, selecting the appropriate tooling, and setting the machine parameters.

- Interpreting blueprints and technical drawings to determine the required machining operations.

- Selecting and installing cutting tools and accessories.

2. Machining

Performing various machining operations, such as boring, drilling, reaming, and tapping, to create the desired features in the workpiece.

- Monitoring the machining process to ensure that the workpiece is being machined to the correct specifications.

- Making adjustments to the machine or tooling as needed to maintain accuracy and efficiency.

3. Inspection and Measurement

Inspecting and measuring the machined workpiece to ensure that it meets the required specifications.

- Using precision measuring instruments, such as calipers and micrometers, to verify dimensions and tolerances.

- Identifying and correcting any errors or defects in the machined workpiece.

4. Maintenance

Performing preventive maintenance and repairs on the horizontal boring mill, including cleaning, lubrication, and troubleshooting.

- Following established maintenance schedules and procedures.

- Troubleshooting and resolving any mechanical or electrical problems that may arise.

Interview Tips

Preparing well for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Horizontal Boring Mill Operator position:

1. Research the Company and Position

Take the time to learn about the company you are applying to, including their history, products or services, and culture. Research the specific position you are applying for to understand the key responsibilities and qualifications required.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Think about the common interview questions you may be asked and prepare your answers in advance. Practice delivering your answers out loud to improve your fluency and confidence.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experiences.

- Focus on highlighting your relevant skills and qualifications, and how they align with the requirements of the position.

3. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally and arrive on time for your interview. This shows that you respect the company’s time and that you are serious about the position.

- Wear clean, pressed clothing that is appropriate for an office environment.

- Be punctual and allow yourself plenty of time to get to the interview location.

4. Be Enthusiastic and Positive

Show the interviewer that you are genuinely interested in the position and the company. Be enthusiastic and positive throughout the interview, and ask thoughtful questions to demonstrate your engagement.

- Smile, make eye contact, and speak clearly and confidently.

- Ask questions about the company, the position, and the industry to show that you are interested and engaged.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Horizontal Boring Mill Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!