Feeling lost in a sea of interview questions? Landed that dream interview for Hose Builder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hose Builder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

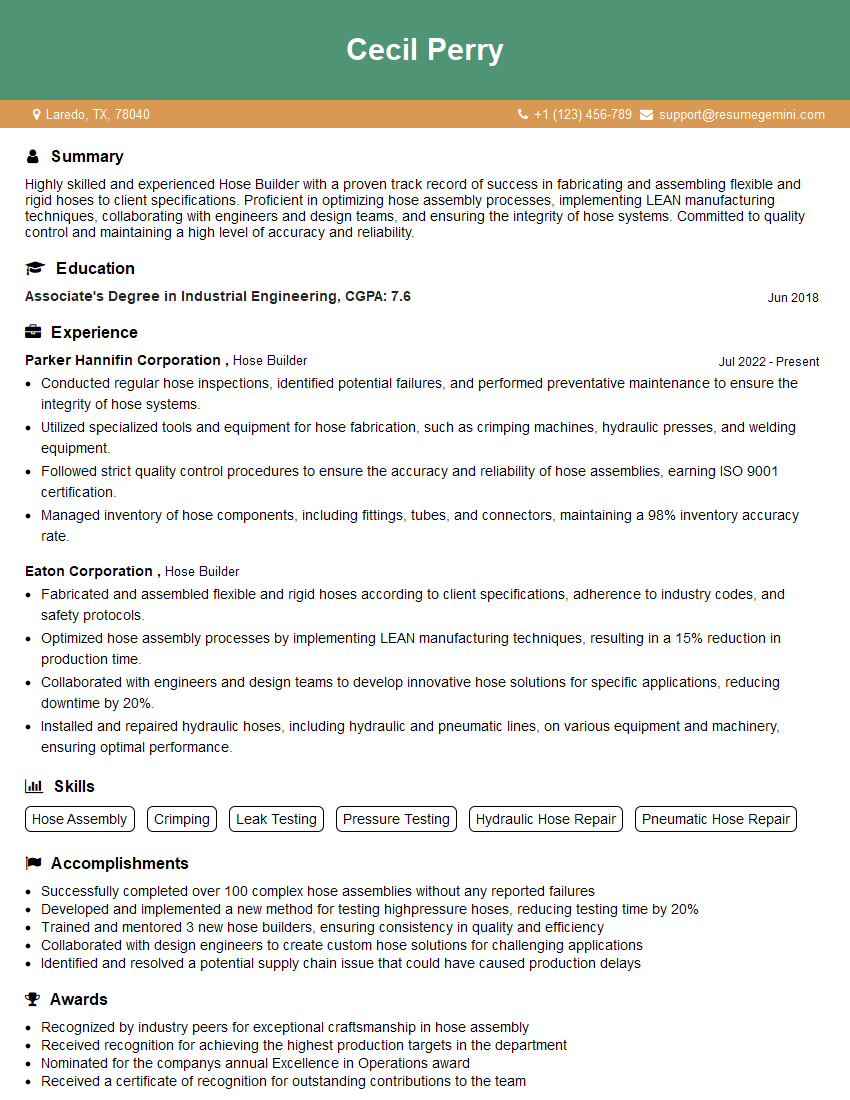

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hose Builder

1. What are the main types of hoses and what are their applications?

Hose Types and Applications:

- Rubber Hoses: General-purpose hoses for water, air, chemicals, and oil. Used in construction, agriculture, and industrial settings.

- PVC Hoses: Lightweight and flexible hoses for water, air, and chemicals. Used in irrigation, pool maintenance, and plumbing.

- Thermoplastic Hoses: Heat-resistant hoses for hot liquids, gases, and chemicals. Used in manufacturing, automotive, and pharmaceutical industries.

- Metal Hoses: Durable and flexible hoses for conveying gases, liquids, and dry materials. Used in chemical processing, power plants, and shipbuilding.

- Composite Hoses: Hoses constructed from multiple materials for specific applications. Provide advantages such as flexibility, durability, and chemical resistance.

2. Describe the process of selecting the correct hose for a specific application.

Factors to Consider:

- Fluid type and temperature

- Flow rate and pressure

- Environmental conditions

- Hose length and diameter

- Flexibility and durability requirements

- Cost and availability

Selection Process:

- Identify fluid properties and operating conditions.

- Determine flow requirements and pressure range.

- Consider environmental factors, such as temperature and UV exposure.

- Select hose materials compatible with the fluid and conditions.

- Choose appropriate hose size based on flow rate and pressure.

- Evaluate flexibility and durability requirements.

- Compare costs and availability of different options.

3. What are the common causes of hose failure and how can they be prevented?

- Overpressure: Exceeding hose pressure rating. Prevented by using correct pressure gauges and relief valves.

- Abrasion: Mechanical damage caused by friction. Prevented by using abrasion-resistant hoses and protective sleeves.

- Corrosion: Chemical attack on hose materials. Prevented by selecting corrosion-resistant hoses or using protective coatings.

- Heat Damage: Exposure to excessive temperatures. Prevented by using heat-resistant hoses and isolating from heat sources.

- Improper Installation: Inadequate support or incorrect mounting. Prevented by following manufacturer’s installation guidelines.

- Aging: Natural degradation over time. Prevented by regular inspection and replacement as per recommended intervals.

4. Describe the different types of hose fittings and when to use each type.

- Barbed Fittings: Used with rubber and PVC hoses, inserted into hose and secured with clamp.

- Cam Fittings: Quick-connect fittings for rapid hose attachment and detachment.

- Compression Fittings: Used with metal hoses, create a seal by compressing the hose.

- Flange Fittings: Connect large-diameter hoses for high-pressure applications.

- Quick-Disconnect Fittings: Allow easy hose removal without tools.

- Threaded Fittings: Used with hoses that have threaded ends.

5. What are the safety precautions to consider when working with hoses?

- Inspect hoses regularly for damage or wear before use.

- Never exceed hose pressure rating.

- Secure hoses properly to prevent movement or snagging.

- Use proper fittings and clamps to prevent leaks or blowouts.

- Handle hoses carefully to avoid kinks or damage.

- Wear appropriate protective gear, such as gloves and safety glasses.

- Be aware of potential hazards, such as corrosive fluids or hot liquids.

6. Describe the process of manufacturing a rubber hose.

- Compounding: Mixing rubber with other ingredients to create the desired properties.

- Extrusion: Forcing the rubber compound through a die to form the hose shape.

- Curing: Vulcanizing the rubber by heating under pressure to enhance its strength and durability.

- Reinforcement: Adding layers of reinforcement, such as fabric or wire, to improve hose strength.

- Final Inspection: Testing and inspecting the hose for quality and performance.

7. What are the latest advancements in hose technology?

- Lightweight and Durable Materials: Using advanced polymers and composites for improved flexibility and strength.

- Smart Hoses: Integrating sensors and electronics into hoses for monitoring pressure, temperature, and flow.

- Eco-Friendly Hoses: Developing bio-based materials and sustainable manufacturing processes to reduce environmental impact.

- High-Performance Hoses: Engineering hoses for extreme environments, such as ultra-high pressure or cryogenic applications.

- Customizable Hose Solutions: Tailoring hoses to meet specific customer requirements and applications.

8. Describe the quality control measures you implement to ensure the reliability of your hoses.

- Raw Material Inspection: Verifying the quality of incoming rubber and other materials.

- In-Process Inspection: Monitoring the manufacturing process and testing hoses at each stage.

- Final Testing: Conducting rigorous performance and durability tests on finished hoses.

- Documentation and Traceability: Maintaining detailed records of all quality checks and test results.

- Continuous Improvement: Regularly reviewing and updating quality control procedures based on data analysis.

9. What are the challenges you have faced in your role as a Hose Builder, and how did you overcome them?

Challenge: Developing a high-pressure hose for a new application

- Solution: Collaborated with engineers to research and design a reinforced hose with improved burst strength and durability.

Challenge: Meeting customer demand for eco-friendly hoses

- Solution: Explored innovative materials and processes, developing a line of biodegradable and recyclable hoses.

10. How do you stay up-to-date with the latest industry trends and advancements in hose technology?

- Attend industry conferences and exhibitions.

- Read trade publications and research papers.

- Engage in online forums and professional development courses.

- Network with other professionals in the field.

- Seek feedback from customers and industry experts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hose Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hose Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hose Builders are responsible for assembling and repairing hoses used in various industries, including automotive, construction, and manufacturing. They must have a thorough understanding of different hose types, materials, and fittings, as well as the ability to follow detailed instructions and work independently.

1. Assembly and Repair of Hoses

Hose Builders are responsible for assembling and repairing hoses according to customer specifications. This includes cutting hoses to length, attaching fittings, and testing for leaks. They must also be able to diagnose and repair any problems that may arise with hoses.

- Cut hoses to length using precision cutting tools.

- Attach fittings to hoses using specialized tools and techniques.

- Test hoses for leaks using pressure testing equipment.

- Diagnose and repair hose problems, such as leaks, kinks, and punctures.

2. Quality Control

Hose Builders are responsible for ensuring that all hoses they assemble or repair meet quality standards. They must inspect hoses for any defects, such as cracks, tears, or bubbles. They must also test hoses to ensure that they meet the required pressure and flow rates.

- Inspect hoses for defects using visual inspection techniques.

- Test hoses to ensure that they meet the required pressure and flow rates.

- Identify and correct any defects found during inspection or testing.

- Maintain a clean and organized work area.

3. Customer Service

Hose Builders may be required to provide customer service to customers who have questions about hoses or hose assemblies. They must be able to answer questions about hose types, materials, and fittings, as well as provide advice on hose selection and installation.

- Answer customer questions about hoses and hose assemblies.

- Provide advice on hose selection and installation.

- Resolve customer complaints and issues.

- Build and maintain positive relationships with customers.

4. Safety

Hose Builders must follow all safety regulations and procedures when working with hoses and hose assemblies. This includes wearing appropriate safety gear, such as gloves, safety glasses, and hearing protection. They must also be aware of the potential hazards associated with working with hoses, such as high pressure and leaks.

- Follow all safety regulations and procedures.

- Wear appropriate safety gear, such as gloves, safety glasses, and hearing protection.

- Be aware of the potential hazards associated with working with hoses.

- Take precautions to prevent accidents and injuries.

Interview Tips

Preparing for a Hose Builder interview can help you increase your chances of being successful.

1. Research the Company and the Position

Before your interview, take some time to research the company and the Hose Builder position. This will help you understand the company’s culture, values, and what they are looking for in a Hose Builder. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website.

- Read the company’s social media pages.

- Check out the company’s Glassdoor page.

- Talk to people who work at the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked in a Hose Builder interview. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with hose assembly and repair?

- What is your quality control process?

- How do you handle customer service issues?

- What are your safety procedures?

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also make sure that your shoes are clean and polished.

- Wear a suit or dress.

- Make sure your clothes are clean and pressed.

- Polish your shoes.

- Accessorize with a watch or jewelry.

4. Be Punctual

Punctuality is important for any interview, but it is especially important for a Hose Builder interview. This shows the interviewer that you are reliable and that you respect their time.

- Plan your route in advance.

- Leave early to allow for traffic and parking.

- Arrive at the interview location 5-10 minutes early.

5. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the position and who are positive about their abilities. Show the interviewer that you are excited about the opportunity to work as a Hose Builder and that you are confident in your abilities.

- Smile and make eye contact.

- Speak clearly and confidently.

- Be positive and enthusiastic about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hose Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!