Are you gearing up for an interview for a Hose Coupling Joiner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hose Coupling Joiner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

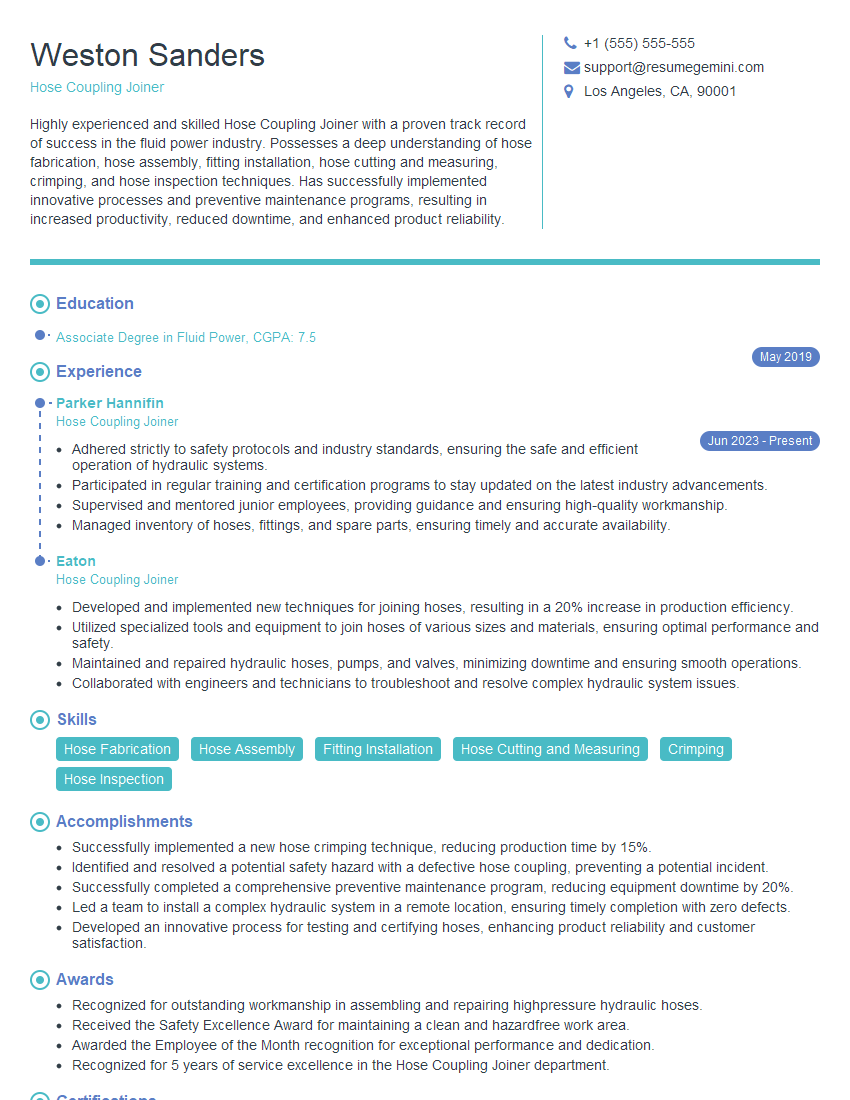

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hose Coupling Joiner

1. What are the different types of hose couplings?

There are various types of hose couplings, each designed for specific applications and industries. Some common types include:

- Camlock Couplings: Quick-connect and disconnect couplings used in fire fighting, irrigation, and construction.

- Thread-On Couplings: Screw-on couplings commonly used in plumbing, gardening, and compressed air applications.

- Quick-Release Couplings: Couplings that allow for fast and easy connection and disconnection, often used in hydraulic and pneumatic systems.

- Push-Fit Couplings: Couplings that connect hoses by simply pushing them together, providing an easy and secure connection.

- Banjo Couplings: Couplings that provide a leak-proof connection between a hose and a port, typically used in automotive and industrial applications.

2. What are the key considerations when selecting a hose coupling?

Material Compatibility

- Ensure that the coupling is made of a material that is compatible with the hose and the fluid being transferred.

- Consider factors such as pressure, temperature, and chemical resistance.

Pressure Rating and Flow Rate

- Select a coupling that can handle the operating pressure and flow rate of the system.

- Exceeding the pressure or flow capacity can lead to leaks or failures.

Coupling Type and Application

- Choose a coupling type that suits the specific application and requirements.

- Consider factors such as the frequency of connection/disconnection, ease of use, and operating environment.

Durability and Reliability

- Select a coupling that is durable and reliable, capable of withstanding environmental conditions and repeated use.

- Consider factors such as corrosion resistance, vibration, and temperature fluctuations.

3. How do you identify and troubleshoot common hose coupling problems?

Common hose coupling problems include leaks, blockages, and connection failures. To troubleshoot:

- Inspect the coupling for damage or defects, such as cracks, dents, or corrosion.

- Check for blockages due to debris or foreign objects in the coupling or hose.

- Ensure proper connection between the coupling and hose, check for loose fittings or misalignment.

- Test the coupling under pressure to identify leaks or failures.

- If necessary, replace or repair the coupling or hose to resolve the issue.

4. What techniques do you use to maintain and extend the lifespan of hose couplings?

To maintain and extend the lifespan of hose couplings:

- Regularly inspect couplings for wear, damage, or corrosion.

- Lubricate couplings according to manufacturer’s instructions to reduce friction and prevent seizing.

- Clean couplings and hoses to remove dirt, debris, or contaminants.

- Store couplings in a dry and protected environment when not in use.

- Avoid overtightening couplings, as this can damage the threads or coupling body.

5. How do you ensure that hose couplings are properly installed and tightened to prevent leaks or failures?

To ensure proper installation and tightening of hose couplings:

- Follow manufacturer’s instructions for the specific coupling type.

- Use the appropriate tools and equipment for tightening, such as a torque wrench.

- Tighten the coupling gradually and evenly to avoid overtightening or cross-threading.

- Check the tightness of the coupling before putting the system into operation.

- Consider using thread sealants or gaskets to enhance sealing and prevent leaks.

6. How do you handle situations where custom hose couplings are required?

When custom hose couplings are required:

- Collaborate with engineers or designers to determine the specific requirements.

- Research and identify manufacturers that specialize in custom hose couplings.

- Provide detailed specifications and drawings to the manufacturer.

- Inspect and test the custom couplings to ensure they meet the required standards.

- Maintain documentation and records of the custom couplings for future reference.

7. What are the safety precautions you take when working with high-pressure hose couplings?

When working with high-pressure hose couplings:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and ear protection.

- Inspect couplings and hoses regularly for damage or wear.

- Never exceed the pressure rating of the coupling or hose.

- Use proper techniques for connecting and disconnecting couplings.

- Keep clear of the hose and coupling during pressurization and operation.

8. How do you stay up-to-date with the latest advancements and best practices in hose coupling technology?

To stay up-to-date with advancements and best practices:

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Consult with manufacturers and industry experts.

- Participate in online forums and discussion groups.

- Conduct research and development to explore innovative solutions.

9. How do you ensure quality control when joining hose couplings?

To ensure quality control:

- Follow established procedures and standards for joining hose couplings.

- Use high-quality materials and components.

- Inspect each joint for proper alignment, tightness, and sealing.

- Pressure test completed assemblies to verify integrity and performance.

- Maintain records and documentation of inspections and tests.

10. How do you handle situations where there are discrepancies or conflicts with hose coupling specifications or standards?

When handling discrepancies or conflicts:

- Review the specifications and standards thoroughly to identify potential issues.

- Consult with suppliers, engineers, or industry experts to clarify requirements.

- Propose alternative solutions or modifications that adhere to safety and performance criteria.

- Document all decisions and actions taken to address the discrepancies.

- Maintain open communication with stakeholders to ensure alignment and resolution.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hose Coupling Joiner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hose Coupling Joiner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Hose Coupling Joiner is responsible for assembling, installing, and maintaining various types of hose couplings and related components, ensuring proper functioning and efficient operations of fluid systems in various industrial and commercial settings.

1. Assembly and Installation

Assembles and installs a range of hose couplings, adapters, and fittings to connect and seal hoses securely.

- Follows established procedures and specifications to ensure proper assembly and installation.

- Uses appropriate tools and equipment, including crimping machines, torque wrenches, and leak detectors.

2. Troubleshooting and Repair

Troubleshoots and repairs faulty hose couplings and assemblies to prevent leaks and maintain system integrity.

- Inspects hose couplings for damage, wear, or leaks, using visual and diagnostic techniques.

- Replaces or repairs defective components, including hose clamps, seals, and O-rings.

3. Quality Control and Maintenance

Conducts quality control inspections and performs regular maintenance tasks to ensure the reliability and longevity of hose couplings.

- Tests and certifies hose couplings to meet required specifications and standards.

- Lubricates, cleans, and inspects hose couplings and related components to prevent corrosion and extend their lifespan.

4. Safety and Compliance

Adheres to all safety regulations and industry standards related to hose coupling assembly and installation.

- Wears appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Follows proper handling and storage procedures for hazardous materials, such as solvents and adhesives.

Interview Tips

Preparing thoroughly for a Hose Coupling Joiner interview is essential to showcase your skills and increase your chances of success. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Position

Research the company’s website, industry publications, and social media platforms to gain insight into their business operations, culture, and the specific requirements of the Hose Coupling Joiner position.

- Review the job description carefully to identify key responsibilities and qualifications.

- Tailor your resume and cover letter to highlight your relevant skills and experience that align with the position.

2. Practice Your Answers to Common Interview Questions

Prepare thoughtful and concise answers to common interview questions related to your skills, experience, and motivations.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples that demonstrate your capabilities.

- Practice delivering your answers out loud to improve your articulation and confidence.

3. Emphasize Your Technical Skills and Experience

Highlight your expertise in assembling, installing, and maintaining various types of hose couplings and related components.

- Quantify your experience by providing specific numbers and metrics, such as the number of hose couplings you have assembled or the number of systems you have maintained.

- Demonstrate your proficiency in using relevant tools and equipment, such as crimping machines, torque wrenches, and leak detectors.

4. Showcase Your Problem-Solving Abilities

Employers value candidates who can effectively troubleshoot and resolve issues. Highlight your analytical skills and ability to identify and fix faulty hose couplings and assemblies.

- Describe specific situations where you successfully diagnosed and resolved hose coupling problems.

- Emphasize your systematic approach to troubleshooting and your ability to work independently or as part of a team.

5. Prepare Questions for the Interviewers

Prepare thoughtful questions to ask the interviewers at the end of the interview. This demonstrates your interest in the position and the company.

- Inquire about the company’s growth plans and industry outlook.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hose Coupling Joiner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!