Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hose Inspector and Patcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

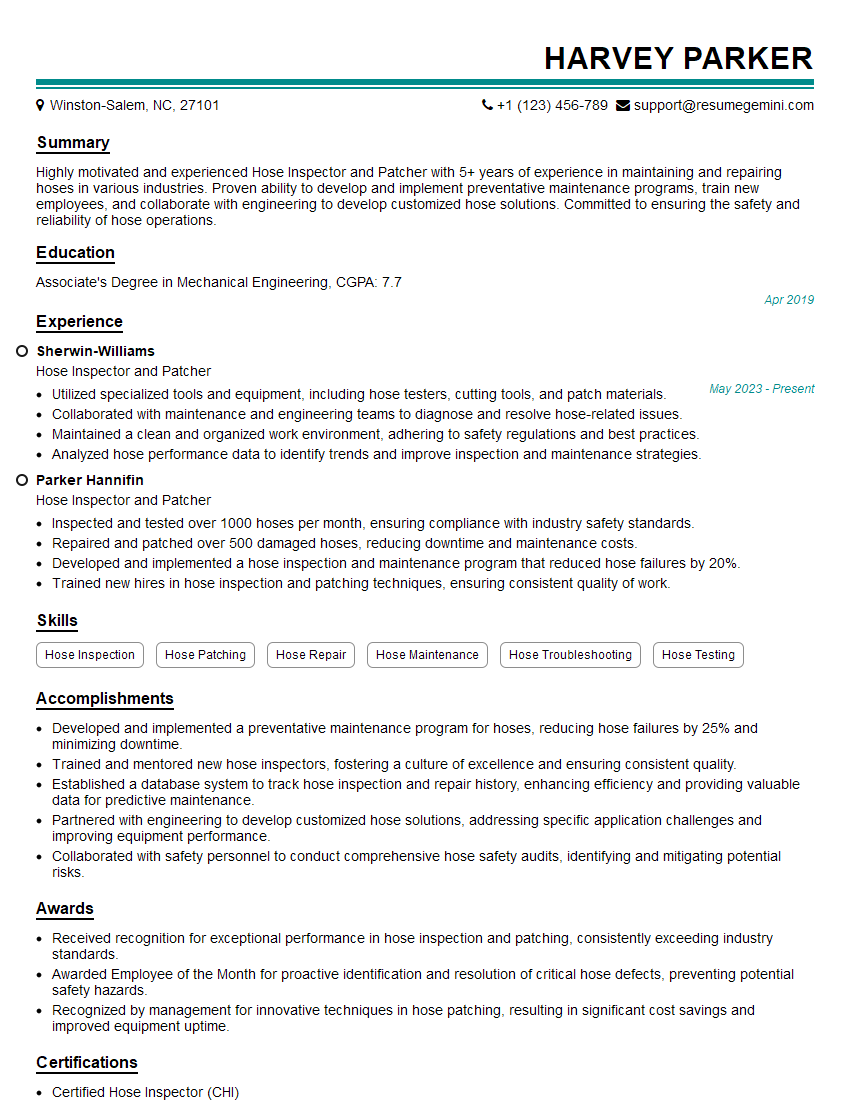

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hose Inspector and Patcher

1. Explain the different types of hose inspections and their purpose?

There are various types of hose inspections, each with a specific purpose:

- Visual Inspection: Examines the hose’s exterior for damages, cracks, bulges, or abrasions.

- Pressure Test: Tests the hose’s ability to withstand internal pressure, identifying leaks or weak points.

- Volumetric Expansion Test: Measures the hose’s ability to expand under pressure, indicating any potential defects.

- Electrical Testing: Verifies the electrical conductivity of hoses used in electrical applications.

- Hydrostatic Testing: Submerges the hose in water and pressurizes it to test its resistance to water penetration.

2. Describe the steps involved in patching a damaged hose?

Pre-Inspection:

- Identify the type of hose and damage present.

- Thoroughly clean and dry the damaged area.

Patch Preparation:

- Cut a patch material slightly larger than the damaged area.

- Apply a suitable adhesive to both the patch and hose surface.

Patching:

- Place the patch over the damaged area and firmly press it into place.

- Allow the adhesive to cure according to the manufacturer’s instructions.

Post-Inspection:

- Visually inspect the patch for proper adhesion and coverage.

- Consider a pressure test to ensure the integrity of the repair.

3. What are the key factors to consider when selecting the appropriate patching material?

- Hose Material: Ensure the patch material is compatible with the type of hose being repaired.

- Damage Severity: Choose a patch size and material that adequately covers and reinforces the damaged area.

- Pressure Requirements: Select a patch material that can withstand the operating pressure of the hose.

- Environmental Conditions: Consider the potential exposure to heat, chemicals, or moisture when selecting the patch material.

4. How do you ensure the safe handling and storage of hoses?

- Proper Storage: Store hoses in a cool, dry place protected from direct sunlight and extreme temperatures.

- Coiling Techniques: Coil hoses loosely to avoid kinks or damage to the inner tube.

- Handling Precautions: Avoid dragging or twisting hoses and use proper supports when transferring them.

- Regular Inspection: Conduct regular inspections to identify any potential damage or wear.

- Safety Training: Educate personnel on proper hose handling and safety guidelines.

5. Describe the maintenance procedures for hose assemblies to extend their lifespan?

- Regular Cleaning: Remove dirt, debris, and chemicals from hoses and fittings.

- Pressure Testing: Periodically conduct pressure tests to detect any leaks or weak spots.

- Visual Inspection: Regularly examine hoses for cracks, abrasions, or other damage.

- Hose Rotation: Regularly rotate hoses to different usage areas to distribute wear evenly.

- Storage Practices: Store hoses properly to prevent damage and prolong their lifespan.

6. What are the common causes of hose failures, and how can they be prevented?

- Abrasion: Protect hoses from sharp objects or excessive friction.

- Chemical Exposure: Use hoses compatible with the chemicals they convey.

- Excessive Pressure: Ensure hoses are used within their rated pressure limits.

- Improper Coiling: Avoid kinking or overtightening hoses.

- Temperature Extremes: Use hoses designed for the operating temperature range.

7. What are the different types of hose connectors and their applications?

- Threaded Connectors: NPT, BSP, and Camlock for secure and leak-proof connections.

- Quick-Disconnect Couplings: Push-to-connect or twist-lock couplers for fast and easy hose changes.

- Hose Barb Connectors: Barbed fittings that create a tight seal when inserted into a hose.

- Hydraulic Fittings: Designed for high-pressure hydraulic applications.

- Specialized Connectors: For specific applications, such as food-grade or anti-static hoses.

8. Describe the importance of regular hose certification and testing?

- Safety: Ensures hoses are operating safely and meet industry standards.

- Compliance: Adheres to regulatory requirements and industry best practices.

- Cost-Effectiveness: Early detection of potential failures prevents costly repairs or downtime.

- Reliability: Certified hoses provide peace of mind and minimize the risk of unplanned outages.

9. How do you prioritize hose inspection and repair needs?

- Critical Applications: Prioritize hoses used in life-safety or essential operations.

- Severity of Damage: Address hoses with significant damage or leaks immediately.

- Usage Frequency: Inspect and repair hoses used frequently more often.

- Historical Data: Consider the failure history of different hose types.

- Regulatory Requirements: Follow any industry- or company-specific inspection schedules.

10. What are the safety precautions you take when working with high-pressure hoses?

- Personal Protective Equipment: Wear appropriate clothing, gloves, and safety glasses.

- Pressure Relief: Release pressure from hoses before disconnecting or handling.

- Secure Connections: Ensure all connections are tight and free of leaks.

- Use Proper Tools: Use properly calibrated tools for pressure testing and inspection.

- Designated Work Areas: Conduct hose inspections and repairs in designated safe locations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hose Inspector and Patcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hose Inspector and Patcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hose Inspector and Patcher is responsible for maintaining and repairing hoses used in various industries, including manufacturing, construction, and firefighting. Their key job responsibilities include:

1. Hose Inspection

Inspect hoses for defects, damage, or wear using visual examination and specialized equipment like pressure gauges and borescopes.

2. Hose Patching

Repair damaged hoses by applying patches using specialized tools and materials, such as vulcanizing rubber or welding.

3. Fabrication

Fabricate new hoses or hose assemblies according to specifications, using materials like rubber, PVC, or metal.

4. Testing

Test repaired or fabricated hoses to ensure they meet industry standards and safety requirements.

5. Maintenance

Perform routine maintenance on hoses and hose systems, including cleaning, lubrication, and replacement of worn components.

6. Documentation

Maintain detailed records of hose inspections, repairs, and testing, ensuring compliance with regulations and quality standards.

Interview Tips

To ace an interview for a Hose Inspector and Patcher position, candidates should prepare thoroughly and highlight their relevant skills and experience.

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry, and research the specific job responsibilities you are applying for.

2. Highlight Relevant Experience

Emphasize your experience in hose inspection, patching, fabrication, and testing. Quantify your accomplishments using specific examples and metrics.

3. Demonstrate Technical Skills

Showcase your proficiency in using specialized equipment, such as pressure gauges, borescopes, and vulcanizing machines. Highlight your understanding of hose materials and industry standards.

4. Emphasize Safety and Quality

Stress your commitment to safety by describing your adherence to established procedures and industry best practices. Highlight your attention to detail and focus on delivering high-quality work.

5. Prepare for Common Interview Questions

Practice answering common interview questions, such as: “Why are you interested in this position?”, “What is your experience with hose inspection?”, and “How do you ensure the quality of your work?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hose Inspector and Patcher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!