Are you gearing up for an interview for a Hose Mender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hose Mender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

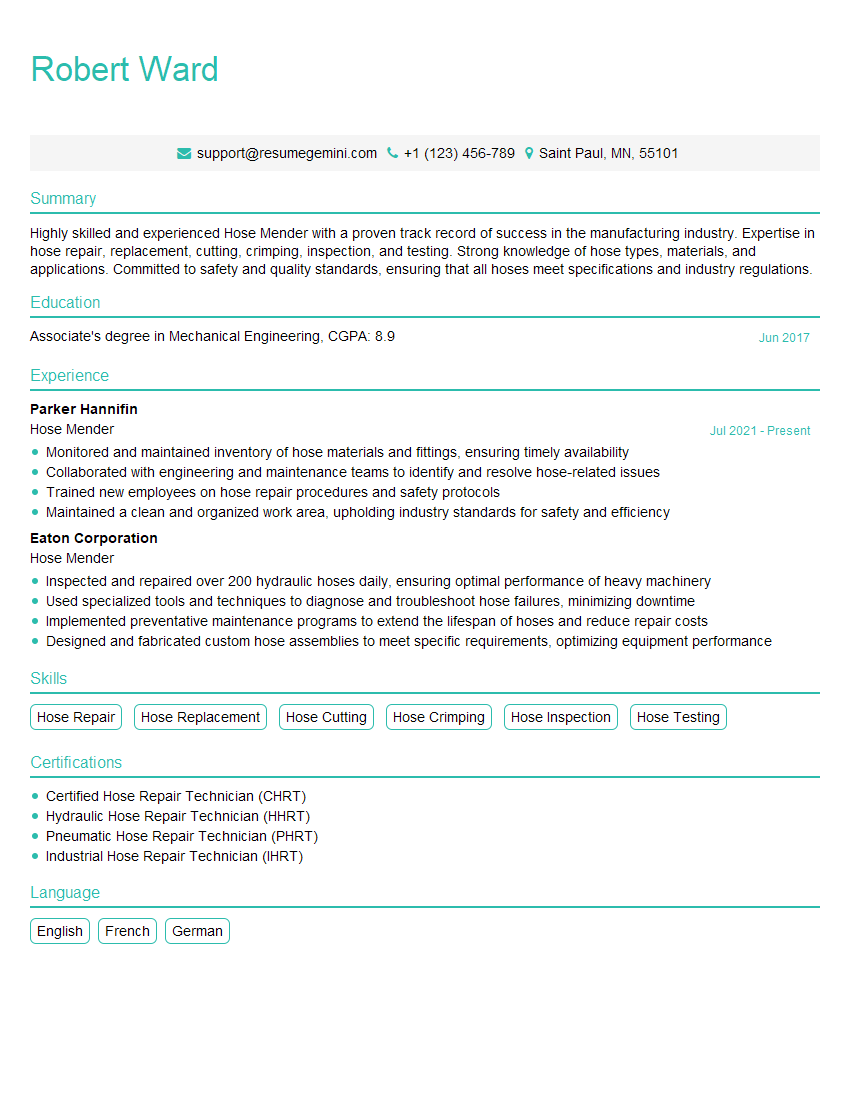

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hose Mender

1. Describe the different types of hose materials and their applications.

Different types of hose materials are used in a variety of applications, such as:

- Rubber: Used for a wide range of applications, including water, air, and oil.

- Polyurethane: Used for applications requiring flexibility, durability, and resistance to chemicals.

- Nylon: Used for high-pressure applications, such as hydraulic lines.

- Stainless steel: Used for applications requiring high strength and resistance to corrosion.

- Teflon: Used for applications requiring high temperature and chemical resistance.

When selecting a hose material, it is important to consider the specific application requirements, such as pressure, temperature, and chemical compatibility.

2. Explain the process of crimping a hose fitting.

Preparing the hose

- Cut the hose to the desired length.

- Remove any burrs or sharp edges from the cut end of the hose.

- Insert the hose into the fitting.

Crimping the fitting

- Place the crimping tool over the fitting.

- Close the crimping tool to crimp the fitting onto the hose.

- Remove the crimping tool.

It is important to crimp the fitting properly to ensure a secure and leak-free connection.

3. What are the different types of hose fittings?

There are many different types of hose fittings, each designed for a specific application.

- Barbed fittings: Used for low-pressure applications.

- Compression fittings: Used for medium-pressure applications.

- Flare fittings: Used for high-pressure applications.

- Push-to-connect fittings: Used for quick and easy connections.

- Quick-disconnect fittings: Used for applications where frequent disconnection is required.

When selecting a hose fitting, it is important to consider the specific application requirements, such as pressure, temperature, and chemical compatibility.

4. What are the safety precautions that should be taken when working with hoses?

When working with hoses, it is important to take the following safety precautions:

- Never use a hose that is damaged or leaking.

- Always inspect hoses before use.

- Do not exceed the maximum pressure rating of the hose.

- Do not use hoses for applications they are not designed for.

- Store hoses in a dry and protected area.

By following these safety precautions, you can help prevent accidents and injuries.

5. What are the benefits of using a hose reel?

Using a hose reel offers several benefits, including:

- Organization: Keeps hoses organized and out of the way.

- Safety: Prevents hoses from becoming tangled or damaged.

- Convenience: Makes it easy to deploy and retract hoses.

- Durability: Protects hoses from wear and tear.

- Space saving: Stores hoses in a compact manner.

Hose reels are available in a variety of sizes and styles to meet the specific needs of any application.

6. What are the common problems that can occur with hoses and how can they be prevented?

Common problems that can occur with hoses include:

- Leaks: Caused by damaged or loose fittings.

- Burst hoses: Caused by exceeding the maximum pressure rating.

- Abrasion: Caused by contact with sharp objects.

- Chemical degradation: Caused by exposure to corrosive chemicals.

- Heat damage: Caused by exposure to excessive heat.

These problems can be prevented by taking the following precautions:

- Inspect hoses before use.

- Do not exceed the maximum pressure rating of the hose.

- Protect hoses from abrasion.

- Avoid exposure to corrosive chemicals.

- Do not expose hoses to excessive heat.

By following these precautions, you can help extend the life of your hoses and prevent costly repairs.

7. What are the different types of hose clamps and how are they used?

There are many different types of hose clamps, each designed for a specific application.

- Worm gear clamps: Used for a wide range of applications.

- Band clamps: Used for applications requiring high torque.

- Oetiker clamps: Used for applications where space is limited.

- Spring clamps: Used for applications where quick and easy installation is required.

When selecting a hose clamp, it is important to consider the specific application requirements, such as pressure, temperature, and chemical compatibility.

8. How do you troubleshoot a leaking hose?

To troubleshoot a leaking hose, follow these steps:

- Inspect the hose for damage or loose fittings.

- Tighten any loose fittings.

- Replace any damaged hoses.

- If the leak persists, contact a professional.

It is important to troubleshoot a leaking hose promptly to prevent further damage or injury.

9. What are the benefits of using a hose with a quick-disconnect fitting?

Using a hose with a quick-disconnect fitting offers several benefits, including:

- Convenience: Makes it easy to connect and disconnect hoses.

- Speed: Reduces the time it takes to connect and disconnect hoses.

- Safety: Prevents spills and leaks.

- Versatility: Allows for multiple hoses to be connected to a single source.

Quick-disconnect fittings are available in a variety of sizes and styles to meet the specific needs of any application.

10. What are the advantages of using a high-pressure hose?

Using a high-pressure hose offers several advantages, including:

- Greater efficiency: High-pressure hoses can transfer more fluid with less energy.

- Smaller size: High-pressure hoses can be smaller than low-pressure hoses for the same flow rate.

- Greater durability: High-pressure hoses are more resistant to wear and tear.

- Reduced maintenance: High-pressure hoses require less maintenance than low-pressure hoses.

High-pressure hoses are used in a variety of applications, such as hydraulic systems, power washers, and air compressors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hose Mender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hose Mender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hose Mender is responsible for inspecting, repairing, and replacing hoses used in various industries, including automotive, industrial, and construction. Their primary duty is to ensure that hoses are functioning properly and safely.

1. Inspection

Inspect hoses for damage, leaks, and wear using visual and tactile methods.

- Examine hoses for cracks, cuts, bulges, or other abnormalities.

- Check for leaks by pressurizing hoses and using a leak detector.

- Measure hose dimensions and fittings to ensure proper fit.

2. Repair

Repair damaged hoses using appropriate tools and techniques.

- Cut and remove damaged sections of hose.

- Install new hose sections and fittings.

- Vulcanize or glue hoses to create a durable bond.

3. Replacement

Replace hoses that cannot be repaired or are beyond their useful life.

- Remove old hoses from equipment or machinery.

- Select and install new hoses that meet the required specifications.

- Tighten fittings and connections to ensure a secure seal.

4. Maintenance

Perform regular maintenance on hoses to prevent failures.

- Inspect hoses for signs of wear or damage.

- Clean hoses and fittings to remove dirt and debris.

- Lubricate fittings to prevent corrosion and ensure smooth operation.

Interview Tips

Preparing for a Hose Mender interview can increase your chances of success. Here are some interview tips to help you ace the interview:

1. Research the Company and Position

Before the interview, research the company, their industry, and the specific role of a Hose Mender within their organization. This knowledge will demonstrate your interest and help you answer questions intelligently.

- Visit the company’s website to learn about their products, services, and values.

- Read industry news and articles to stay informed about current trends and best practices.

- Review the job description carefully to identify the essential qualifications and responsibilities.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and qualifications. Practice answering these questions clearly and concisely, highlighting your relevant abilities and accomplishments.

- Describe your experience in hose inspection, repair, and replacement.

- How do you ensure the quality of your work and meet industry standards?

- Tell us about a challenging hose repair you successfully completed.

3. Showcase Your Technical Skills

Demonstrate your technical skills and knowledge of hose materials, fittings, and repair techniques. Employers will want to know that you have the necessary expertise to perform the job effectively.

- Discuss your experience with different types of hoses, including rubber, plastic, and metal.

- Explain how you identify and repair common hose failures, such as leaks, cracks, and bulges.

- Describe your understanding of hose safety regulations and industry standards.

4. Emphasize Your Safety Awareness

In this role, safety is paramount. Highlight your commitment to safety by explaining how you follow safety protocols and procedures, wear appropriate protective gear, and ensure the safety of yourself and others in the workplace.

- Discuss your knowledge of OSHA regulations and industry best practices for hose handling and repair.

- Explain how you identify potential safety hazards and take appropriate measures to mitigate them.

- Share any experience or training you have in emergency response or accident prevention.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hose Mender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!